Novel process for purifying crude product and commercial 2-mercaptobenzothiazole by CO2 method

A technology of mercaptobenzothiazole and new process, which is applied in the refining field of 2-mercaptobenzothiazole, can solve the problems of high production cost, difficulty in solvent extraction, influence on the quality of finished products, etc., achieves low requirements for equipment, simple and direct judgment, The effect of extracting large sample volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

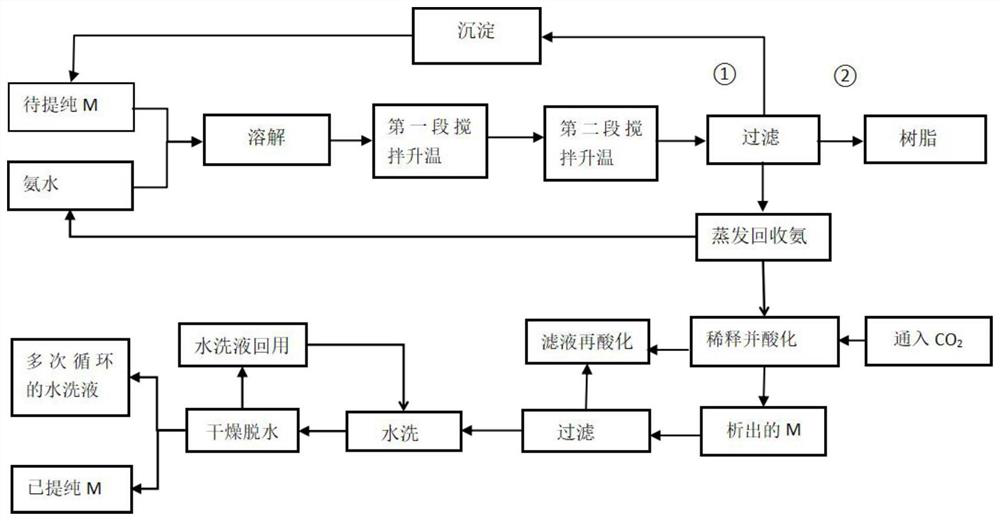

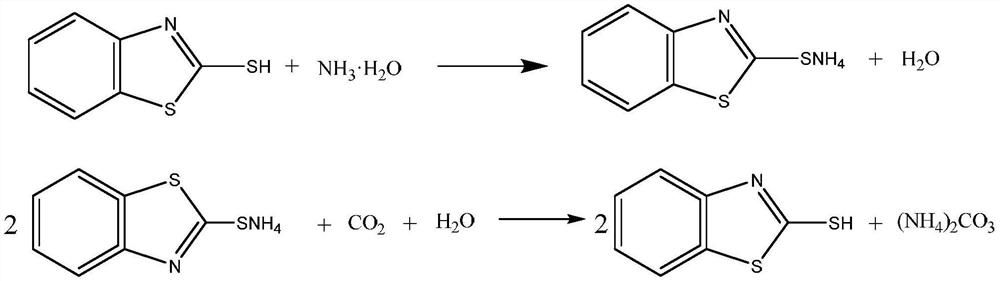

[0034] Such as figure 1 CO shown 2 The new technique of method purification crude product and commodity 2-mercaptobenzothiazole comprises the following steps:

[0035] (1) Add the unpurified M (initial melting point: 119°C) directly produced by the M production plant and containing a large amount of crude resin into ammonia water for mixing and dissolving in 6 times, and stir at a stirring rate of 60r / min , quickly raised the temperature to 30°C, and maintained the temperature for 10 minutes, then continued to heat up to 60°C, after a period of time, the solution gradually became clear until there were obvious brown viscous precipitates and dark yellow clear liquids, and the precipitates were removed by filtration (at this time Precipitation is all resin, as shown in (2) in the accompanying drawing), obtain the dark yellow clear liquid containing M ammonium salt, wherein the concentration of ammoniacal liquor is 5wt%, and the mol ratio of M and ammoniacal liquor is 1:2.25;

...

Embodiment 2

[0040] Such as figure 1 CO shown 2 The new technique of method purification crude product and commodity 2-mercaptobenzothiazole comprises the following steps:

[0041](1) Add the commercial product M (initial melting point: 166.5°C) purified by solvent extraction into ammonia water all at once for mixing and dissolving, stir at a stirring speed of 200r / min, rapidly raise the temperature to 40°C, and keep the temperature for 20 minutes, and then continue to heat up to 55°C. After a period of time, the solution gradually becomes clear until there are obvious brown precipitates and dark yellow clear liquids, and the precipitates are removed by filtration (all the precipitates at this time are resins, as shown in ② in the attached drawing. ), obtain the dark yellow clear liquid containing M ammonium salt, wherein the concentration of ammoniacal liquor is 10wt%, and the mol ratio of M and liquefied ammonia is 1:4;

[0042] (2) After diluting the above-mentioned clarified liquid w...

Embodiment 3

[0046] Such as figure 1 CO shown 2 The new technique of method purification crude product and commodity 2-mercaptobenzothiazole comprises the following steps:

[0047] (1) The commercial product M (initial melting point: 167°C) purified by the traditional acid-base method was added into ammonia water three times for mixing and dissolving, stirred at a stirring rate of 400r / min, rapidly raised to 70°C, and kept The temperature was 3h, and then continued to heat up to 90°C. After a period of time, the solution gradually became clear until obvious light yellow precipitate and dark yellow clear liquid appeared, and the precipitate was removed by filtration (the precipitate at this time included resin and part of undissolved M, As shown in ① in the accompanying drawing), obtain the deep yellow clear liquid containing M ammonium salt, wherein the concentration of ammoniacal liquor is 25wt%, and the mol ratio of M and ammoniacal liquor is 1:1;

[0048] (2) Dilute the above clarifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com