A method for purifying pea albumin pa1a using negatively charged polysaccharides

A negatively charged, albumin technology, applied in the field of protein extraction, can solve the problems of high cost, high price, low separation speed, etc., and achieve the effects of easy scale, low equipment requirements, and less polysaccharide consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

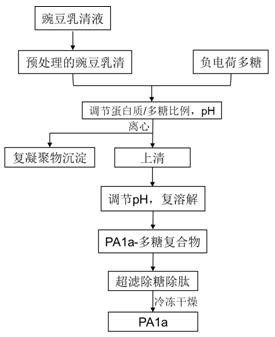

Method used

Image

Examples

Embodiment 1

[0025] (1) Pretreatment of pea whey: adjust the pH of pea whey to 4.5 with 2 mol / L hydrochloric acid, let it stand at 4°C for 48 hours, centrifuge at 8000rpm for 20 minutes, remove the precipitate, and add 1 mol / L NaOH solution to adjust The pH of the supernatant was adjusted to 7.0 to obtain the pretreated pea whey liquid.

[0026] (2) Negatively charged polysaccharide complex coacervation and precipitation of PA2 and lectin in pea whey protein: Weigh 400 mg of carboxymethylcellulose powder (molecular weight 250 kDa), dissolve it in 100 mL of deionized water, and stir it magnetically for 2 h. It dissolves completely. Add 20% (v / v) carboxymethyl cellulose solution to the pea whey, mix well, adjust the pH to 4.12, stir magnetically for 15 minutes, and centrifuge (4000 rpm, 20 minutes) to remove complex aggregates and precipitates , to collect the supernatant to obtain the crude protein extract of PA1a and carboxymethyl cellulose.

[0027] (3) Purification of PA1a pea albumin:...

Embodiment 2

[0034](1) Pretreatment of pea whey: adjust the pH of pea whey to 4.6, let it stand at 4°C for 24 h, centrifuge at 4000 rpm for 30 min, remove the precipitate, add 1 mol / L NaOH solution to adjust the pH of the supernatant to 7.5, obtaining the pretreated pea whey liquid.

[0035] (2) Negatively charged polysaccharide complex coacervation and precipitation of PA2 and lectin in pea whey protein: Weigh 450 mg of dextran sulfate powder (molecular weight 500 kDa), dissolve it in 100 mL of deionized water, and stir it magnetically for 1 h to make it completely dissolved. Add 10% (v / v) dextran sulfate solution to the pea whey, mix well, adjust the pH to 4.60, stir magnetically for 25 min, and centrifuge (6000 rpm, 15 min) to remove the precipitate of complex aggregates, Collect the supernatant to obtain the crude protein extract of PA1a and dextran sulfate.

[0036] (3) Purification of PA1a pea albumin: adjust the pH of the above solution to 7.5, remove polysaccharides by ultrafiltr...

Embodiment 3

[0041] (1) Pretreatment of pea whey: adjust the pH of pea whey to 4.8, let it stand at 4°C for 48 h, centrifuge at 6000 rpm for 15 min, remove the precipitate, add 1 mol / L NaOH solution to adjust the pH of the supernatant to 7.0, to obtain the pretreated pea whey.

[0042] (2) Negatively charged polysaccharide complex coacervation and precipitation of PA2 and lectin in pea whey protein: Weigh 500 mg of sodium alginate powder (molecular weight 390 kDa), dissolve it in 100 mL of deionized water, and stir it magnetically for 2 h to make it completely dissolve. Add 20% (v / v) sodium alginate solution to the pea whey, mix well, adjust the pH to 3.9, stir magnetically for 30 min, and centrifuge (4000 rpm, 20 min) to remove complex aggregates and precipitates, collect The supernatant is the crude protein extract of PA1a and sodium alginate.

[0043] (3) Purification of PA1a pea albumin: adjust the pH of the above solution to 8.0, remove polysaccharides by ultrafiltration (100 kDa) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com