A method for the comprehensive recovery of all elements by roasting biomass to reduce oceanic cobalt-rich crusts

A technology for cobalt-rich crusts and biomass, applied in the direction of improving process efficiency, can solve the problems of slow reduction rate of oceanic cobalt-rich crusts and high energy consumption for roasting, and achieve the effects of improving metal leaching rate and reducing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

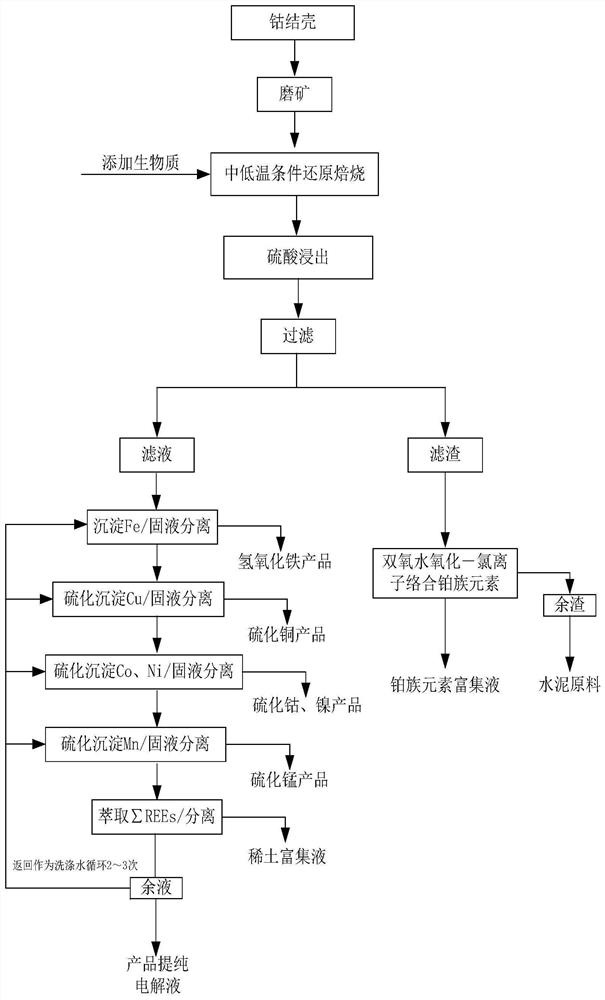

[0070] Such as figure 1 Shown, a kind of biomass roasting reduction oceanic cobalt-rich crust comprehensively recovers the method for all elements, comprising the following steps:

[0071] Step 1. Dry-grind the oceanic cobalt-rich crust until -200 mesh accounts for more than 90%;

[0072] Step 2. Mix the fine-grained cobalt-rich crusts obtained in step 1 with 15% to 20% of dried biomass, and roast in a roasting device at 450 to 500°C for 6 to 10 minutes. Nitrogen gas is introduced at a certain flow rate during the roasting process. Prevent oxidation of reduced products;

[0073] Step 3, leaching the roasted slag obtained by pyrolysis of step 2 at room temperature, in a sulfuric acid solution with a liquid-solid ratio of 3:1 to 5:1, and a sulfuric acid concentration of 1.0 to 1.4 mol / L, at a stirring speed of 300 to 400 rpm / min for 40 Filter after ~60min;

[0074] Step 4, adjust the pH value of the filtrate obtained in step 2 with 0.1mol / L NaOH solution to be 2 to 3.2, after...

Embodiment 2

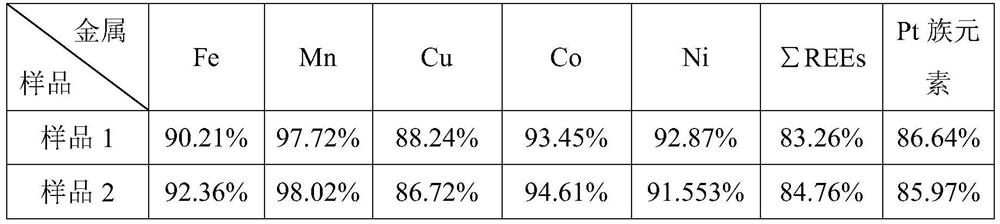

[0082] A method for comprehensively recovering all elements by roasting biomass to reduce oceanic cobalt-rich crusts. The samples of cobalt-rich crusts from two different stations on the ocean floor are respectively taken, and experiments are carried out according to the method described in Example 1.

[0083] Grind samples 1 and 2 to -200 mesh, accounting for more than 90%, and dry them for later use, and dry the sawdust for later use. Samples 1 and 2 were mixed evenly with 15% dried sawdust, and roasted in a roasting device at 4500°C for 60 minutes. Nitrogen gas was introduced at a certain flow rate during the roasting process to prevent the reduction products from being oxidized.

[0084] The roasted slag was leached for 40 minutes at room temperature, in a sulfuric acid solution with a liquid-solid mass ratio of 3:1 and a sulfuric acid concentration of 1.0 mol / L, and filtered at a stirring speed of 350 rpm / min for 40 minutes to obtain filtrate 1 and filter residue 1. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com