Method for preparing fermented soybean-flavored sparerib-flavored spice

A rib-flavored, soy-flavored technology, which is applied in the field of food processing, can solve the problems of insufficient characteristic aroma, unfull mouthfeel, and weak aroma intensity, and achieve the effects of full mouthfeel, avoiding burnt taste, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

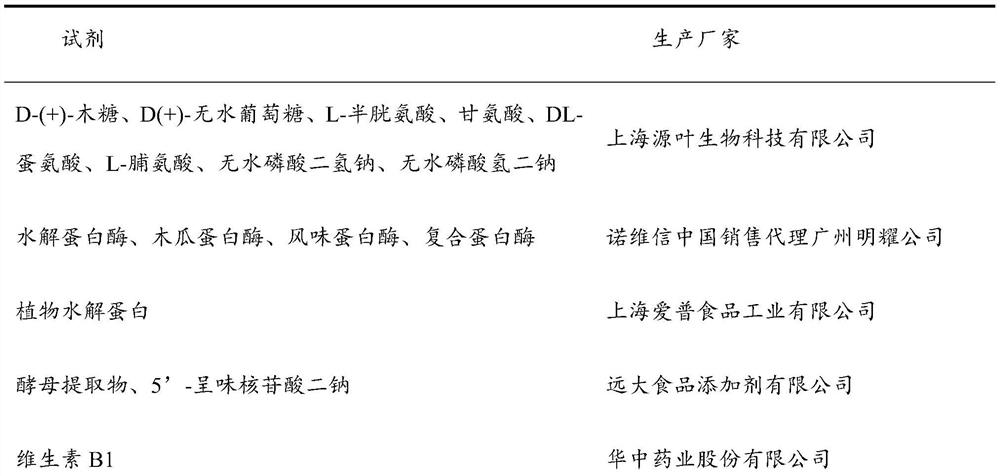

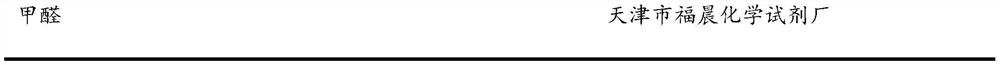

Method used

Image

Examples

Embodiment 1

[0045] The kind of embodiment 1 protease is on the influence of aroma production effect

[0046]Add 10g of minced and heat-treated pork as a substrate to five 50ml conical flasks, add water with a solid-to-liquid ratio of 1:1, and adjust the pH to 7.0. Add 2% papaya to each of the five conical flasks Protease and compound protease, papain and protease hydrolysis, papain and flavor protease, flavor protease and protease hydrolysis, flavor protease and compound protease, placed in a shaking incubator (55°C, 120r / min), after reacting for 2 hours, the triangular Place the bottle in a constant temperature water bath (90°C, 15min) to inactivate the enzyme to obtain an enzymatic hydrolysis solution. The Maillard reaction substrate, that is, 3% xylose, 1.5% glucose, 0.5% VB1, 0.1% L-cysteine, 0.5% glycine, 0.5% plant hydrolyzed protein, 0.5% yeast extract , 4% salt, 2.5% ginger powder, 1% onion powder, 0.1% star anise, 0.2% 5'-flavored nucleotide disodium, 3.5% soy sauce were added ...

Embodiment 2

[0054] The addition amount of embodiment 2 protease is on the influence of aroma production effect

[0055] In five 50ml conical flasks, add 10g of minced and heat-treated pork as a substrate, add water with a material-to-liquid ratio of 1:1, and adjust the pH to 7.0. Each of the five conical flasks is added with 50% of pork mass 1%, 1.5%, 2%, 2.5%, 3% papain and flavor protease were placed in a shaking incubator (55°C, 120r / min), and after reacting for 2h, the triangular flask was placed in a constant temperature water bath (90 ℃, 15min) to inactivate the enzyme. The Maillard reaction substrate, that is, 3% xylose, 1.5% glucose, 0.5% VB1, 0.1% L-cysteine, 0.5% glycine, 0.5% plant hydrolyzed protein, 0.5% yeast extract , 4% salt, 2.5% ginger powder, 1% onion powder, 0.1% star anise, 0.2% 5'-flavored nucleotide disodium, 3.5% soy sauce were added to the enzymolysis solution, reacted at 100°C for 1h, cooled to 35°C -45℃, to be tested.

[0056] The amount of protease added h...

Embodiment 3

[0062] Embodiment 3 The influence of enzymolysis temperature on the effect of aroma production

[0063] Add 10g of minced and heat-treated pork as a substrate to six 50ml conical flasks, add water with a solid-to-liquid ratio of 1:1, and adjust the pH to 7.0. Add 2% papaya to each of the six conical flasks Protease and flavor protease were placed in a shaking incubator (120r / min), and reacted at 40°C, 45°C, 50°C, 55°C, 60°C, and 65°C for 2 hours, and then placed the triangular flask in a constant temperature water bath (90°C, 15min) to inactivate the enzyme. The Maillard reaction substrate, that is, 3% xylose, 1.5% glucose, 0.5% VB1, 0.1% L-cysteine, 0.5% glycine, 0.5% plant hydrolyzed protein, 0.5% yeast extract , 4% salt, 2.5% ginger powder, 1% onion powder, 0.1% star anise, 0.2% 5'-flavored nucleotide disodium, 3.5% soy sauce were added to the enzymolysis solution, reacted at 100°C for 1h, cooled to 35°C -45℃, to be tested.

[0064] The catalysis of enzymes is greatly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com