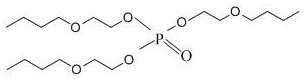

Micro-channel reaction equipment and preparation method of halogen-free organophosphorus flame retardant

A microchannel reaction and equipment technology, applied in organic chemistry, chemical instruments and methods, chemical/physical/physical chemical reactors, etc., can solve the problems of consumption of phosphorus oxychloride, prolongation of reaction cycle, side reactions, etc., to achieve Effects of increased purity and production efficiency, improved reaction efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

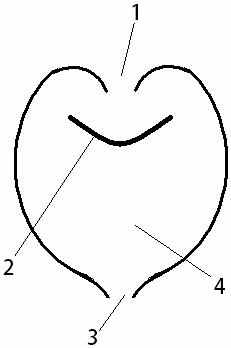

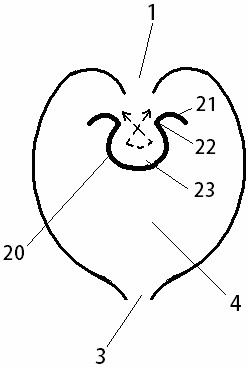

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, take by weighing 1.5g titanium tetrachloride and join in the 150g phosphorus oxychloride bottle, take by weighing 378g isooctyl alcohol in the second bottle, with diaphragm pump at 15g / min, with Hanbang pump at 37.8g / min speed, into the module of the microchannel reactor, the temperature of the reaction module is set to 40 ℃, after passing through 5 reaction modules, it is collected in a closed container, and after alkali washing, water washing, steam distillation and filtration, the content of 99.8%, yield 94%.

Embodiment 2

[0052] Embodiment 2, take by weighing 1.5g titanium tetrachloride and join in the 150g phosphorus oxychloride bottle, take by weighing 382g isooctyl alcohol in the second bottle, use diaphragm pump at 20g / min, use Hanbang pump at 50.93g / min speed, into the module of the microchannel reactor, the temperature of the reaction module is set to 60 ℃, after passing through 5 reaction modules, it is collected in a closed container, and after alkali washing, water washing, steam distillation and filtration, the content of 99.7%, yield 98.5%.

Embodiment 3

[0053] Embodiment 3, get 1.5g titanium tetrachloride and join in the 150g phosphorus oxychloride bottle, take by weighing 390g isooctyl alcohol in the second bottle, with diaphragm pump at 30g / min, with Hanbang pump at 78 g / min The speed of min is injected into the module of the microchannel reactor, and the temperature of the reaction module is set at 70°C. After passing through 5 reaction modules, it is collected in a closed container, washed with alkali, washed with water, steam distilled, filtered, and the content is 99.5 %, yield 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com