Preparation of magnesium-aluminum bimetal oxide modified straw biomass charcoal composite material and application of magnesium-aluminum bimetal oxide modified straw biomass charcoal composite material to removal of phosphorus in wastewater

A bimetallic oxide, straw biomass carbon technology, applied in water pollutants, other chemical processes, water/sewage treatment, etc., can solve the problems of secondary pollution, low efficiency, large amount of chemical reagents, etc. performance, energy saving, environmental protection and recycling, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of magnesium-aluminum double metal oxide modified rice straw biomass charcoal composite material (Mg-Al / SF), comprises the steps:

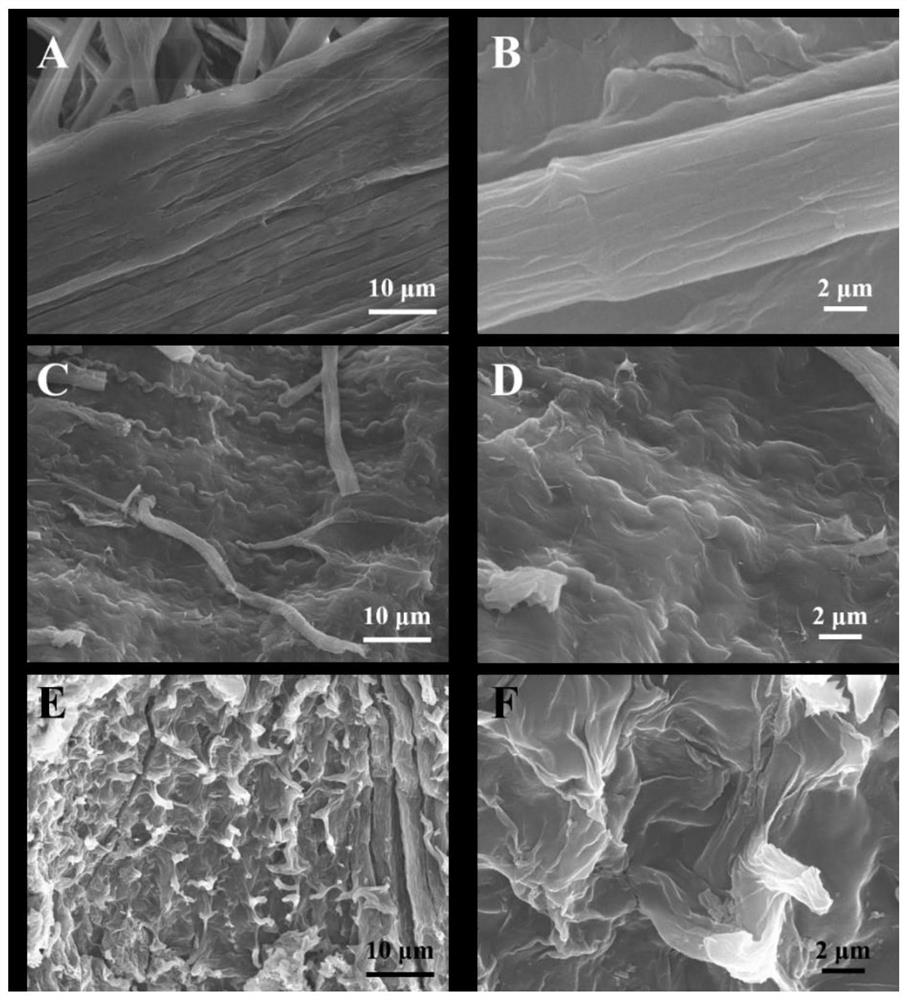

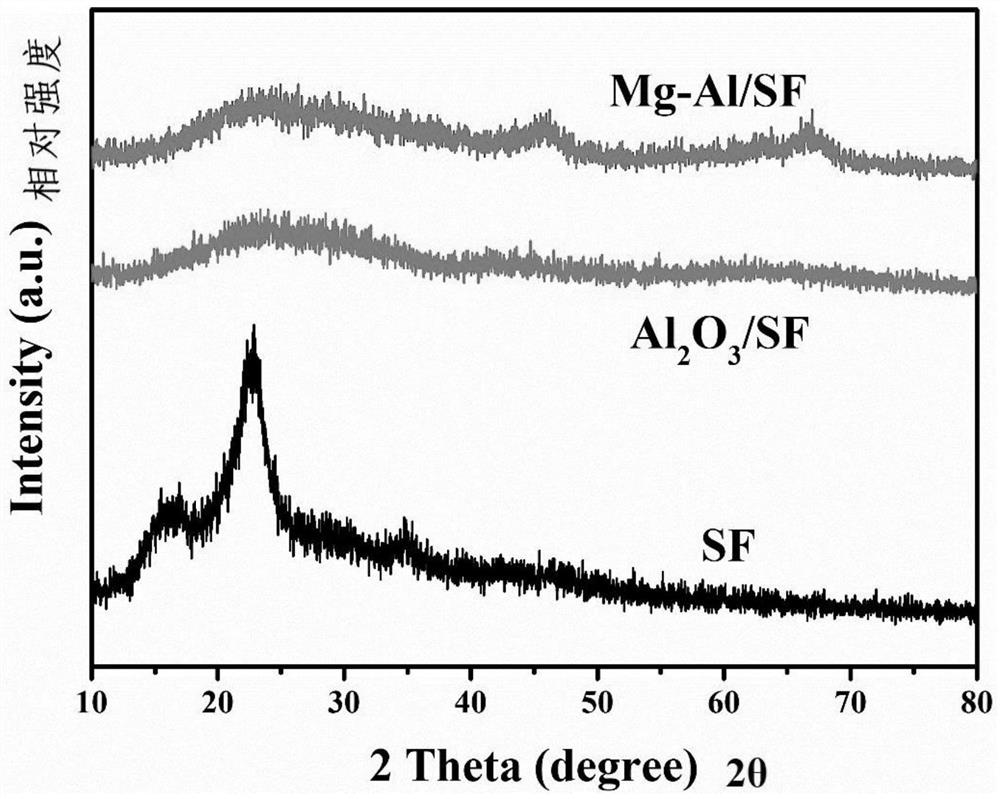

[0031] a) Soak the crushed rice straw in 0.1M sodium hydroxide solution, stir at 40°C for 1 hour, after removing impurities, wash the obtained yellow filamentous fibers with deionized water, and then add acetic acid acidified sodium chlorite solution ( mass fraction 5%), carry out decolorization treatment, then the decolorized biomass is cleaned with deionized water, and dried to obtain straw fiber (SF);

[0032] b) Prepare 0.15M aluminum nitrate nonahydrate solution, soak the obtained straw fiber (SF) for 4h and filter, dry the obtained sample and calcinate at 200°C for 2h under nitrogen to obtain alumina-coated straw fiber (Al 2 o 3 / SF);

[0033] c) According to the solid-to-liquid ratio of 0.3g:0.2g:0.05g:50mL, magnesium nitrate hexahydrate, Al 2 o 3 / SF, hexamethylenetetramine was dissolved in deionized...

Embodiment 2

[0038] A kind of preparation method of magnesium-aluminum double metal oxide modified rice straw biomass charcoal composite material (Mg-Al / SF), comprises the steps:

[0039]a) Soak the crushed rice straw in 0.5M sodium hydroxide solution, stir at 80°C for 5h, remove impurities, wash the obtained yellow filamentous fibers with deionized water, and then add acetic acid acidified sodium chlorite solution ( Mass fraction 5%) is decolorized, then the decolorized biomass is cleaned with deionized water, and dried to obtain straw fiber (SF);

[0040] b) Prepare 0.45M aluminum nitrate nonahydrate solution, soak the obtained straw fiber (SF) for 14h and filter, dry the obtained sample and calcinate at 350°C for 6h under nitrogen to obtain alumina-coated straw fiber (Al 2 o 3 / SF);

[0041] c) According to the solid-to-liquid ratio of 0.6g:0.4g:0.75g:120mL, magnesium nitrate hexahydrate, Al 2 o 3 / SF, hexamethylenetetramine dissolved in deionized water, after fully stirring, the su...

Embodiment 3

[0046] A kind of preparation method of magnesium-aluminum double metal oxide modified rice straw biomass charcoal composite material (Mg-Al / SF), comprises the steps:

[0047] a) Soak the crushed straw in 1M sodium hydroxide solution, stir for 3 hours at 80°C, remove impurities, wash the obtained yellow filamentous fibers with deionized water, and then add acetic acid acidified sodium chlorite solution (mass Fraction 5%) for decolorization, then the decolorized biomass is cleaned with deionized water, and dried to obtain straw fiber (SF);

[0048] b) Prepare a 0.5M nonahydrate aluminum nitrate solution, soak the obtained straw fiber (SF) for 8 hours, filter it, dry the obtained sample and calcinate it at 400°C for 4 hours in nitrogen to obtain alumina-coated rice straw fiber (Al 2 o 3 / SF);

[0049] c) According to the solid-to-liquid ratio of 1.2g:0.5g:0.65g:75mL, magnesium nitrate hexahydrate, Al 2 o 3 / SF, hexamethylenetetramine was dissolved in deionized water, after fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com