A processing method and production line for a lightweight protective door

A processing method and technology of protective doors, applied to other household appliances, household appliances, household components, etc., can solve the problems of heavy protective door structure, cumbersome transportation process, high transportation cost, etc., and achieve flexible and changeable structural configuration design. Low transportation cost and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

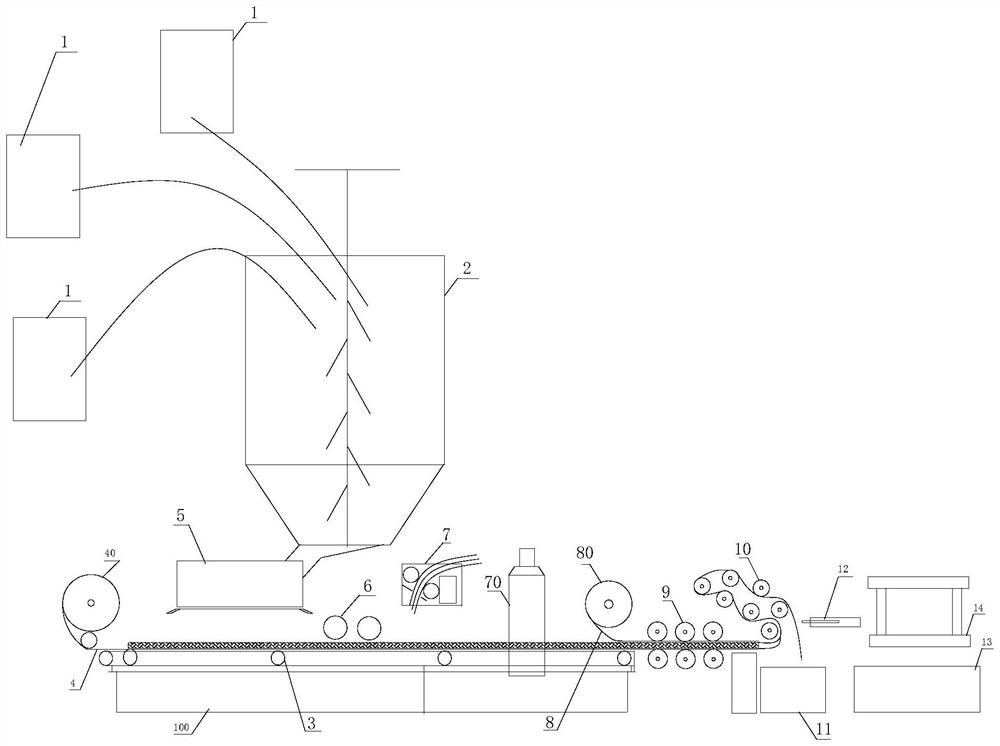

[0029] Example 1, such as figure 1 As shown, the present embodiment provides a processing method for a lightweight protective door. The lightweight protective door is made of base materials and fillers through mixing, extrusion and high-temperature stamping. The processing method includes the following steps:

[0030] Step 1: Mixing materials, adding the base material into the material distribution cylinder 1 and dissolving and diluting with water, and then sending it into the mixing cylinder 2 for stirring and mixing evenly to obtain the diluted mixed base material;

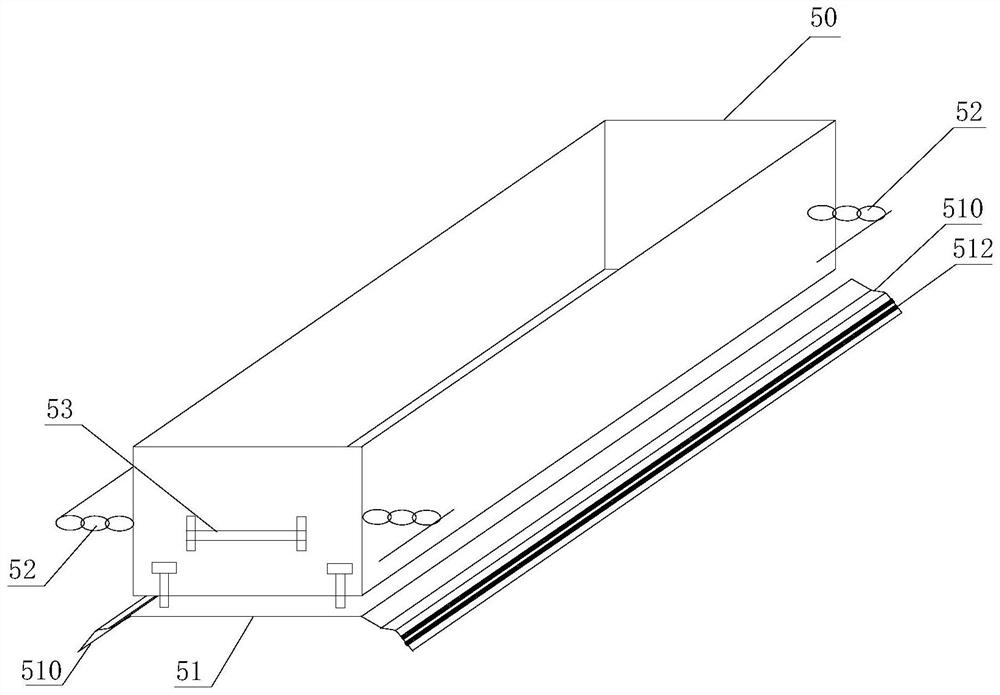

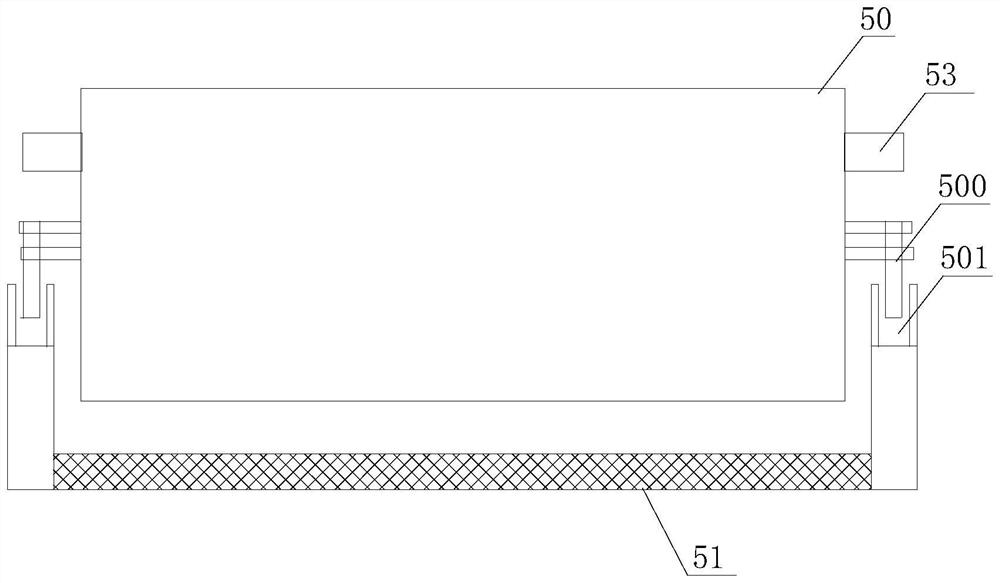

[0031] Step 2: spreading the material, laying the conveying material belt 3 on the conveying support frame 100, laying the supporting material film 4 on the conveying material belt 3, and flowing the diluted mixed base material into the distribution tank device 5 from the bottom of the mixing cylinder 2, The diluted mixed base material is evenly distributed from the distribution tank device 5 and spread flat on ...

Embodiment 2

[0036] Example 2, such as figure 1 As shown, this embodiment provides a light-weight protective door processing method. The lightweight protective door is made of base materials and fillers through mixing, extrusion and high-temperature stamping. In this embodiment, the sealing Sealing is sealed and sealed at 50°C for 96 hours; high-temperature stamping in the door panel stamping die is carried out at a temperature not lower than 150°C for more than 1 hour; the lightweight protective door is made of base material and added inorganic fiber or Organic fibers are used as fillers through compound processing of mixing, extrusion and high-temperature stamping; the base material is composed of the following raw materials: 400 kg of stone powder, 200 kg of unsaturated polyester resin, 90 kg of nano-magnesium salt whiskers, and 80 kg of solvent , shrinkage additive 120 kg, release agent 25 kg, color paste 15 kg, curing agent 8 kg, polymerization inhibitor 4 kg, anti-phase separation ag...

Embodiment 3

[0037] Example 3, such as figure 1 As shown, this embodiment provides a light-weight protective door processing method. The lightweight protective door is made of base materials and fillers through mixing, extrusion and high-temperature stamping. In this embodiment, the sealing Sealing is sealed and sealed at 65°C for 100-120 hours; the high-temperature stamping of the stamping die is carried out at a temperature of 170°C for more than 5-10 hours, and the lightweight protective door is made of base material and added inorganic fiber or organic fiber As a filler, it is made through compound processing of mixing, extrusion and high-temperature stamping; the base material is composed of the following raw materials: 445 kg of stone powder, 180 kg of unsaturated polyester resin, 75 kg of nano-magnesium salt whiskers, 70 kg of solvent, shrinkage additive 108 kg, release agent 17.5 kg, color paste 11 kg, curing agent 5.1 kg, polymerization inhibitor 2 kg, anti-phase separation agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com