Ketene concrete glue reducing agent and preparation method thereof

A technology of ketene and concrete, which is applied in the field of ketene concrete reducer and its preparation, can solve the problems of side reactions, unstable effect of reducer, and no obvious improvement in the strength of concrete in the later stage, so as to reduce free energy, Reduce secondary agglomeration and good cement dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

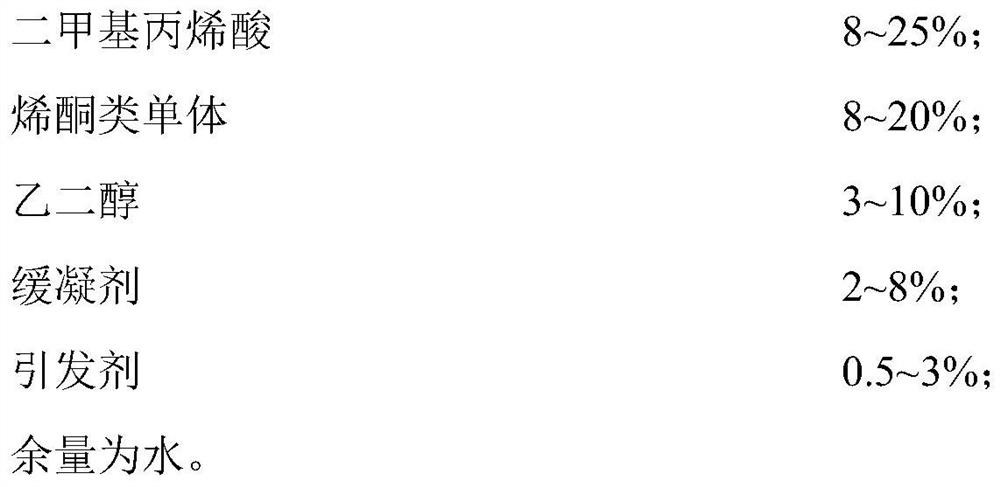

[0029] A kind of ketene type concrete reducer and preparation method thereof, comprising the following raw materials in weight percentage:

[0030]

[0031] The preparation method of a ketene-based concrete glue reducer according to the present invention is realized by the following steps: 1) adding diketene, dimethacrylic acid, and ethylene glycol into a reflux reaction tank, starting to stir and gradually heating up, Finally, the temperature was raised to 110°C, and the heating time was controlled at 40 minutes;

[0032] 2) After the temperature is raised to 110°C, start to drop 1 part of ammonium persulfate solution with a mass percentage concentration of 6% in the solution system, control the dropping speed, and ensure that the dropping time is 2 hours, and the temperature of the solution system remains constant during the dropping process. Keep constant, continue the constant temperature reaction for 5 hours after the dropwise addition;

[0033] 3) After the polymeriz...

Embodiment 2

[0035] A kind of ketene type concrete reducer and preparation method thereof, comprising the following raw materials in weight percentage:

[0036]

[0037] The preparation method of a ketene-based concrete glue reducer according to the present invention is realized by the following steps: 1) adding diketene, dimethacrylic acid, and ethylene glycol into a reflux reaction tank, starting to stir and gradually heating up, Finally, the temperature was raised to 120°C, and the heating time was controlled at 40 minutes;

[0038] 2) After the temperature is raised to 120°C, start to drop 1.5 parts of ammonium persulfate solution with a mass percent concentration of 6% in the solution system, control the rate of addition, and ensure that the addition time is 2.5 hours, and the temperature of the solution system remains constant during the addition process. Keep constant, continue the constant temperature reaction for 4 hours after the dropwise addition;

[0039] 3) After the polym...

Embodiment 3

[0041] A kind of ketene type concrete reducer and preparation method thereof, comprising the following raw materials in weight percentage:

[0042]

[0043] The preparation method of a ketene-based concrete adhesive reducer according to the present invention is realized by the following steps: 1) adding methyl ketene, dimethacrylic acid, and ethylene glycol into the reflux reaction tank, starting to stir and gradually heating up , and finally raised the temperature to 115°C, and controlled the heating time to 35 minutes;

[0044] 2) After the temperature is raised to 115°C, start to drop 1.2 parts of ammonium persulfate solution with a mass percent concentration of 5% in the solution system, control the rate of addition, and ensure that the addition time is 2 hours, and the temperature of the solution system remains constant during the addition process. Keep constant, continue the constant temperature reaction for 4.5 hours after the dropwise addition;

[0045] 3) After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com