A kind of preparation method and application of grease that can customize sn-2 position fatty acid

A sn-2, fatty acid technology, applied in the field of oils and fats, can solve the problem of uncontrollable sn-2 fatty acid, etc., and achieve the effect of easy industrial production, cost reduction, and stable fatty acid composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

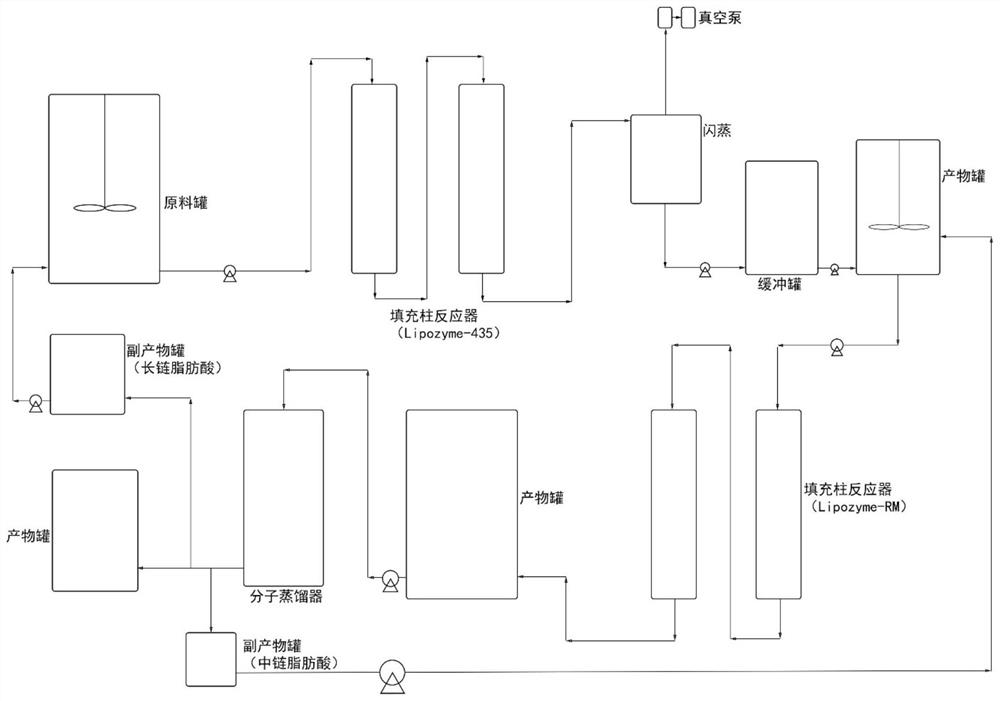

[0045] A kind of preparation method of the grease of the present embodiment that can customize sn-2 position fatty acid, comprises the following steps:

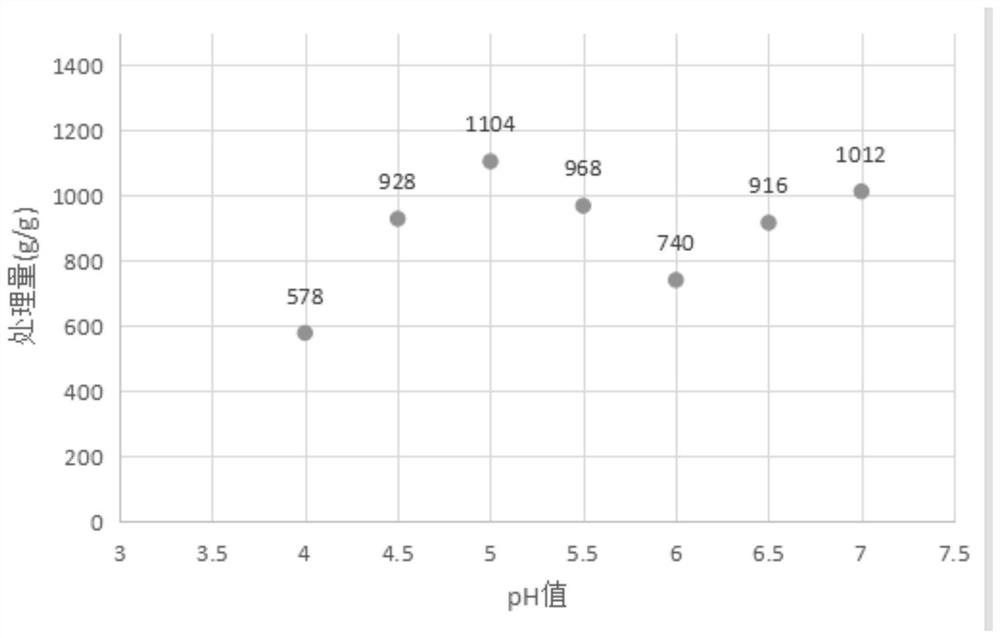

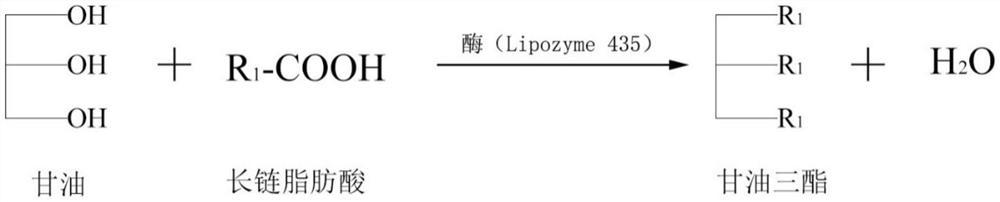

[0046] (1) Glycerin and oleic acid are mixed evenly, and the molar ratio of glycerol and oleic acid is 1:3, pass through the reactor of the packed column that immobilized lipase is housed, and described immobilized lipase is Lipozyme-435, carries out Esterification reaction, the temperature of the esterification reaction is 50°C, the pH value is 5.0, and the flow rate is 1 times the amount of immobilized lipase to obtain triolein and water, and the water in the product is removed by distillation;

[0047] (2) The glyceryl trioleate is mixed with caprylic acid, the molar ratio of glyceryl trioleate and caprylic acid is 1:2, by a packed column reactor equipped with 1,3-specific lipase, the The 1,3-specific lipase is Lipozyme-RM, and the transesterification reaction is carried out. The temperature of the transesterification reac...

Embodiment 2

[0052] A kind of preparation method of the grease of the present embodiment that can customize sn-2 position fatty acid, comprises the following steps:

[0053] (1) Glycerin and docosahexaenoic acid are mixed evenly, and the molar ratio of glycerol and docosahexaenoic acid is 1:4, by the reactor of the packed column that immobilized lipase is housed, described The immobilized lipase is Lipozyme-435, and the esterification reaction is carried out. The temperature of the esterification reaction is 60°C, the pH value is 6.0, and the flow rate is 2.5 times the amount of the immobilized lipase to obtain triglyceride and water. The water in the product removal by distillation;

[0054] (2) The triglyceride is mixed with capric acid, the molar ratio of triglyceride and capric acid is 1:5, and the 1,3-specific lipase is passed through a packed column reactor, and the 1 ,3-specific lipase is Lipozyme-RM, for transesterification reaction, the temperature of transesterification reaction...

Embodiment 3

[0059] A kind of preparation method of the grease of the present embodiment that can customize sn-2 position fatty acid, comprises the following steps:

[0060] (1) Glycerol and linolenic acid are mixed evenly, the molar ratio of glycerol and linolenic acid is 1:5, pass through the reactor of the packed column that immobilized lipase is housed, and described immobilized lipase is Lipozyme-435, carries out Esterification reaction, the temperature of the esterification reaction is 70°C, the pH value is 7.0, and the flow rate is 4 times the amount of immobilized lipase to obtain triglyceride and water, and the water in the product is removed by distillation;

[0061] (2) The triglyceride is mixed with lauric acid, the molar ratio of triglyceride and lauric acid is 1:8, and the 1,3-specific lipase is passed through a packed column reactor, and the 1 ,The 3-specific lipase is Lipozyme-RM, and the transesterification reaction is carried out. The temperature of the transesterificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com