Preparation method of plant essential oil mosquito-repellent microcapsule

A technology of plant essential oils and microcapsules, applied in botany equipment and methods, animal repellants, plant growth regulators, etc., can solve the problems of short repellent time and easy volatility, and achieve the effect of improving the sustained release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

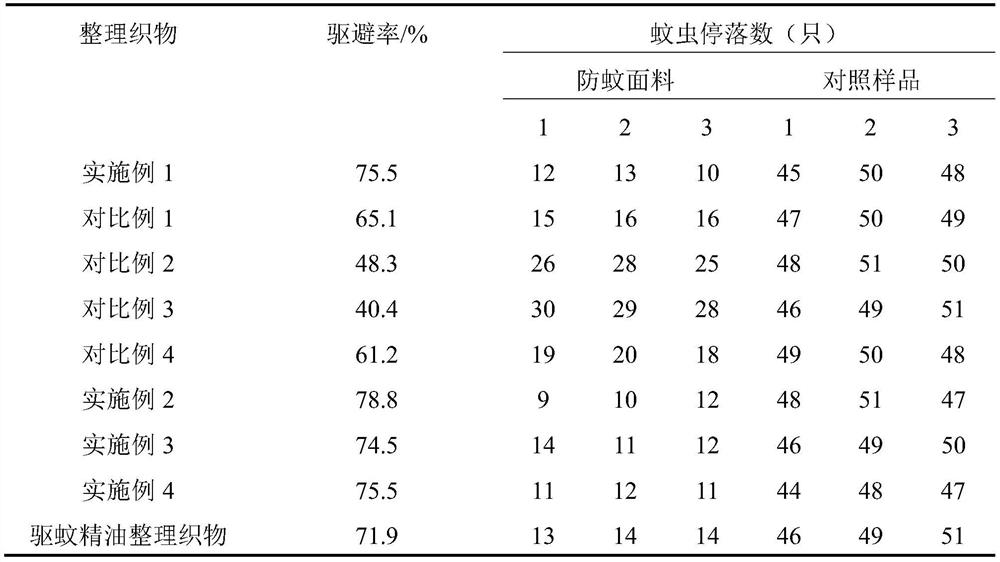

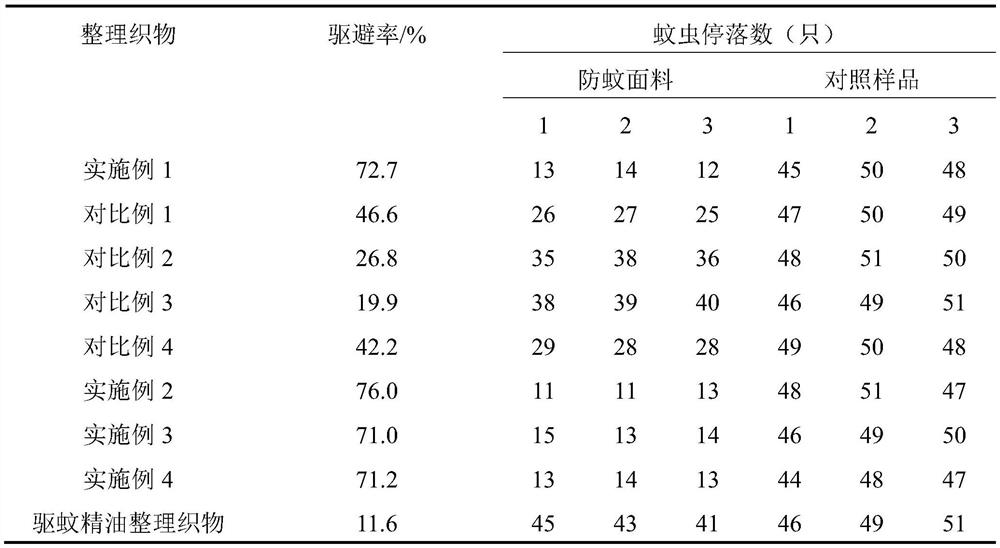

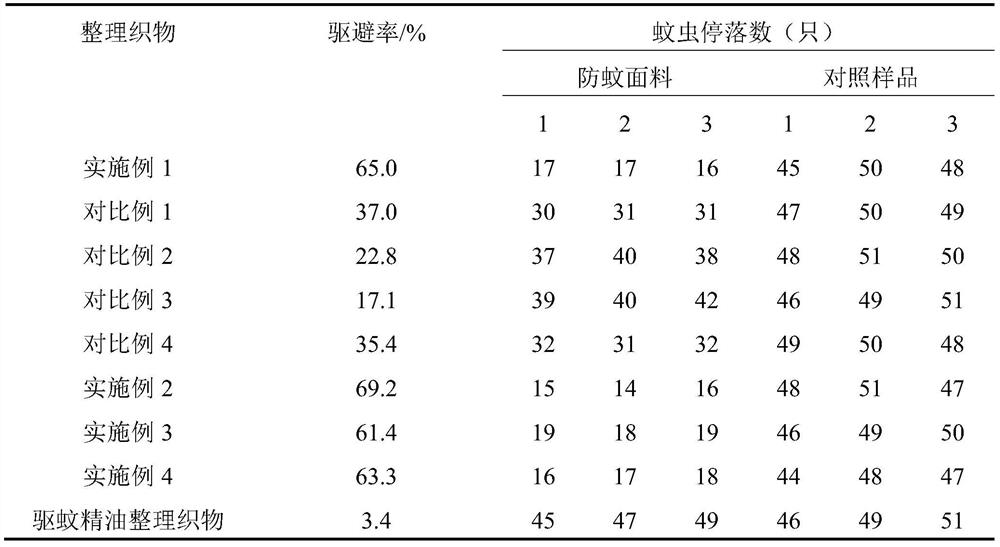

Examples

Embodiment 1

[0028] (1) After fully dissolving sodium alginate with deionized water, adjust the pH to 8 with a NaOH solution with a mass fraction of 10%, and add a mechanical stirring device, N 2 In the four-necked flask of the inlet, thermometer and reflux condensing device, add N-isopropylacrylamide, the mass ratio of sodium alginate to N-isopropylacrylamide is 1:5; 2 After 15 minutes, add the initiator azodicyanovaleric acid, the amount of which accounts for 1% of the mass of N-isopropylacrylamide monomer; under the protection of nitrogen, react at 60°C for 6 hours, add mercaptoacetic acid, whose amount accounts for N- 5% of the mass of isopropylacrylamide monomer; continue to react for 1 hour, after the reaction is completed, cool to room temperature, add absolute ethanol to precipitate the crude product, and dry it in vacuum; extract the crude product with acetone for 24 hours to remove the homopolymer and unreacted monomers, vacuum-dried to a constant amount to obtain carboxyl-termi...

Embodiment 2

[0046] (1) After fully dissolving sodium alginate with deionized water, adjust the pH to 9 with a NaOH solution with a mass fraction of 10%, and add a mechanical stirring device, N 2 Into the four-necked flask of the inlet, thermometer and reflux condensing device, add N-isopropylacrylamide, the mass ratio of sodium alginate to N-isopropylacrylamide is 1:10; 2 After 15 minutes, add the initiator azodicyanovaleric acid, the amount of which accounts for 3% of the mass of N-isopropylacrylamide monomer; under nitrogen protection, react at 75°C for 3 hours, add mercaptoacetic acid, whose amount accounts for N- 10% of the mass of isopropylacrylamide monomer; continue to react for 1 hour, after the reaction is completed, cool to room temperature, add absolute ethanol to precipitate the crude product, and dry it in vacuum; extract the crude product with acetone for 24 hours to remove the homopolymer and unreacted monomers, vacuum-dried to a constant amount to obtain carboxyl-terminat...

Embodiment 3

[0050] (1) After fully dissolving sodium alginate with deionized water, adjust the pH to 8.5 with a NaOH solution with a mass fraction of 10%, and add a mechanical stirring device, N 2 Into the four-necked flask of the inlet, thermometer and reflux condensing device, add N-isopropylacrylamide, the mass ratio of sodium alginate to N-isopropylacrylamide is 1:6; 2After 15 minutes, add the initiator azodicyanovaleric acid, the amount of which accounts for 2% of the mass of N-isopropylacrylamide monomer; under the protection of nitrogen, react at 65°C for 4 hours, add mercaptoacetic acid, whose amount accounts for N- 6% of the mass of isopropylacrylamide monomer; continue to react for 1 hour, after the reaction is completed, cool to room temperature, add absolute ethanol to precipitate the crude product, and dry it in vacuum; extract the crude product with acetone for 24 hours to remove the homopolymer and unreacted monomers, vacuum-dried to a constant amount to obtain carboxyl-ter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com