Continuous polymerization reaction process of polyamide

A technology for polymerization reaction and polyamide, which is applied in the field of continuous polymerization reaction process of polyamide, can solve problems such as expensive steam, and achieve the effects of high purity, guaranteed quality, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

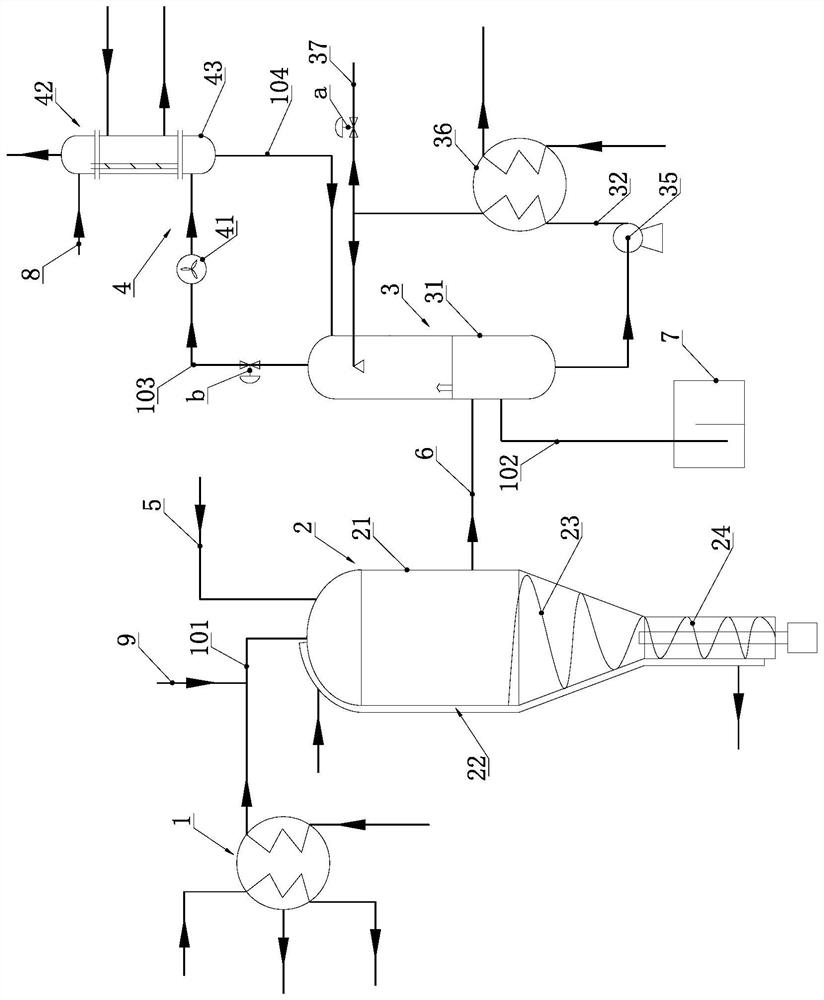

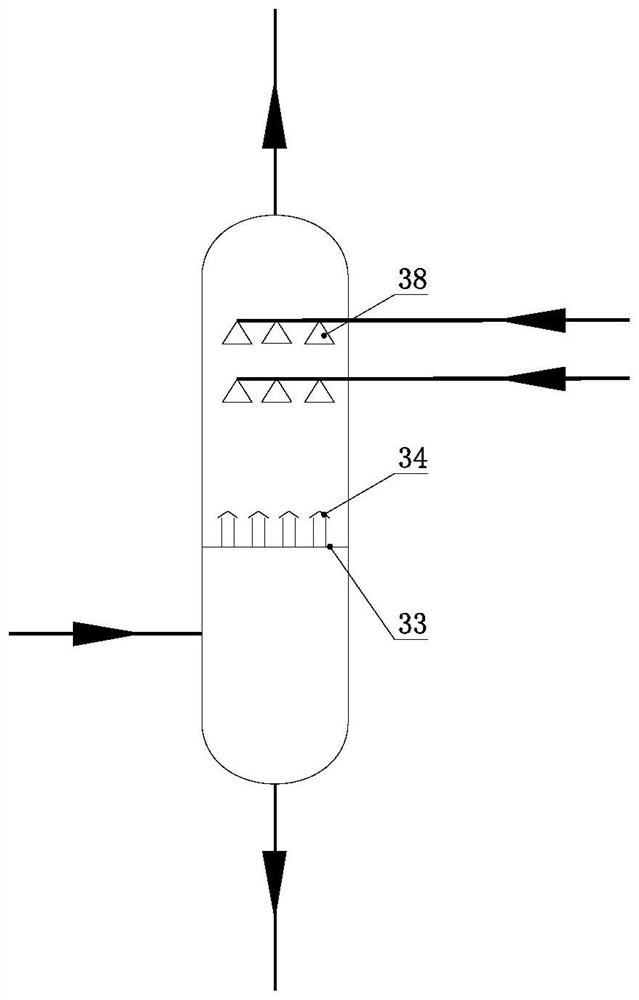

[0036] see figure 1 , image 3 and Figure 4 , is a specific embodiment of the polymerization device used in the continuous polymerization process of the present invention. The polymerization device includes a raw material preheating system 1, a polymerization reaction system 2, a steam condensation system 3, and a vacuum system 4. In this embodiment, the shell side of the raw material preheating system 1 is a heat medium channel, and the tube of the raw material preheating system 1 The tube side is a material channel, and the tube side is one or two tubes, and each tube is serpentine and extends through the shell side. The polymerization reaction system 2 includes a reaction tank body 21, the tank wall of the reaction tank body 21 is provided with a heat medium interlayer 22, and the reaction tank body 21 is provided with a stirring device 23, and the material inlet of the reaction tank body 21 passes through the first The pipeline 101 is connected to the material outlet o...

Embodiment 2

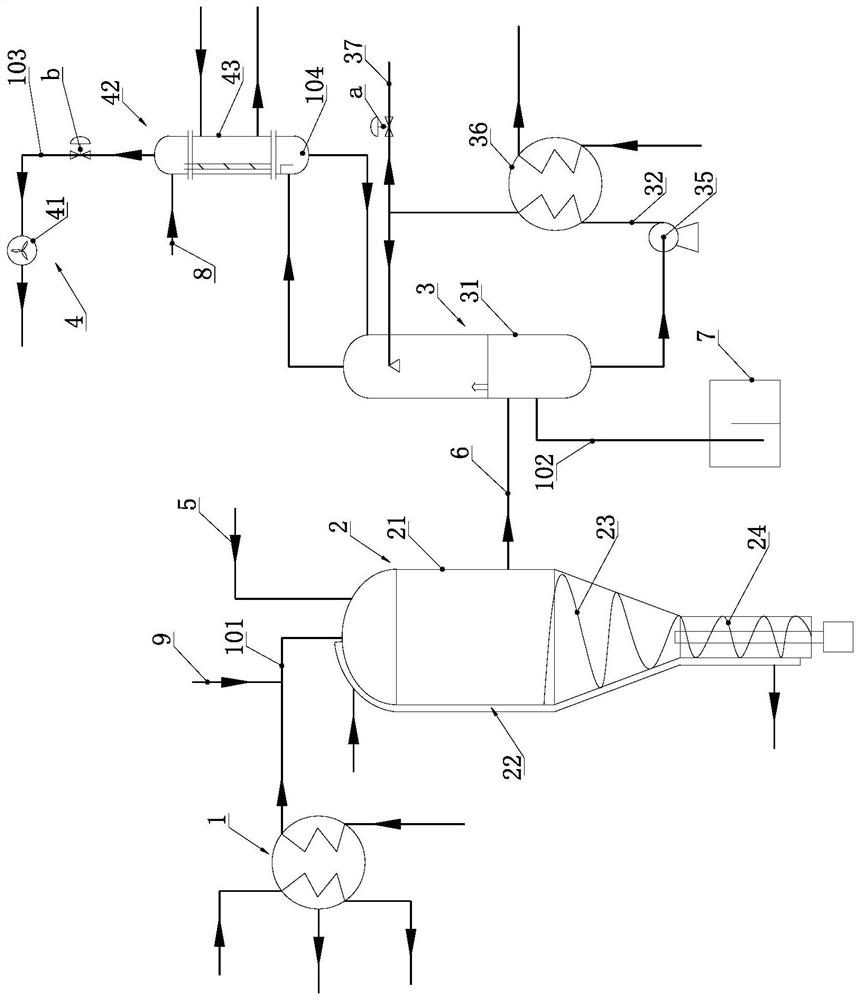

[0038] see figure 2 , is another specific embodiment of the polymerization device used in the continuous polymerization process of the present invention. In this embodiment, the washing tank body 43 is located upstream of the dry vacuum pump 41, the top of the condensation tower body 31 is connected to the washing tank body 43 through a pipeline, and is located below the second partition 45, and the top of the washing tank body 43 is connected to the washing tank body 43 through a pipe Road is connected with the inlet of dry vacuum pump 41. All the other structures are the same as in Embodiment 1.

Embodiment 3

[0039] Embodiment three uses the polymerization device of embodiment one to carry out continuous polymerization reaction

[0040] The nitrogen source provides nitrogen to the polymerization reaction system through the nitrogen pipeline, so that the polymerization reaction system is in a protective atmosphere, and the vacuum system evacuates the polymerization reaction system to form a negative pressure environment of 30-50KPaA, and the desalted water enters the washing tank, and After passing through several rows of tubes, it enters the condensation tank from the fourth pipeline, forms a circulation in the condensation tank and the condensed water circulation pipeline, and the liquid seal tank forms a liquid seal on the downstream end of the second pipeline. The pre-polymerized material (mixed with dicarboxylic acid and organic diamine) at 230°C has an average molar molecular weight of 230. It is heated to 273°C through the raw material preheating system, and then enters the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com