Preparation method of ferroferric oxide coated diamond Fenton-like catalyst

A technology of triiron tetroxide and diamond is applied in the field of preparation of Fenton-like catalysts, which can solve the problems of unrecyclable catalysts, human and animal teratogenic and carcinogenic, and complex dye structures, so as to reduce secondary pollution and reduce red mud. The effect of simple production, preparation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a

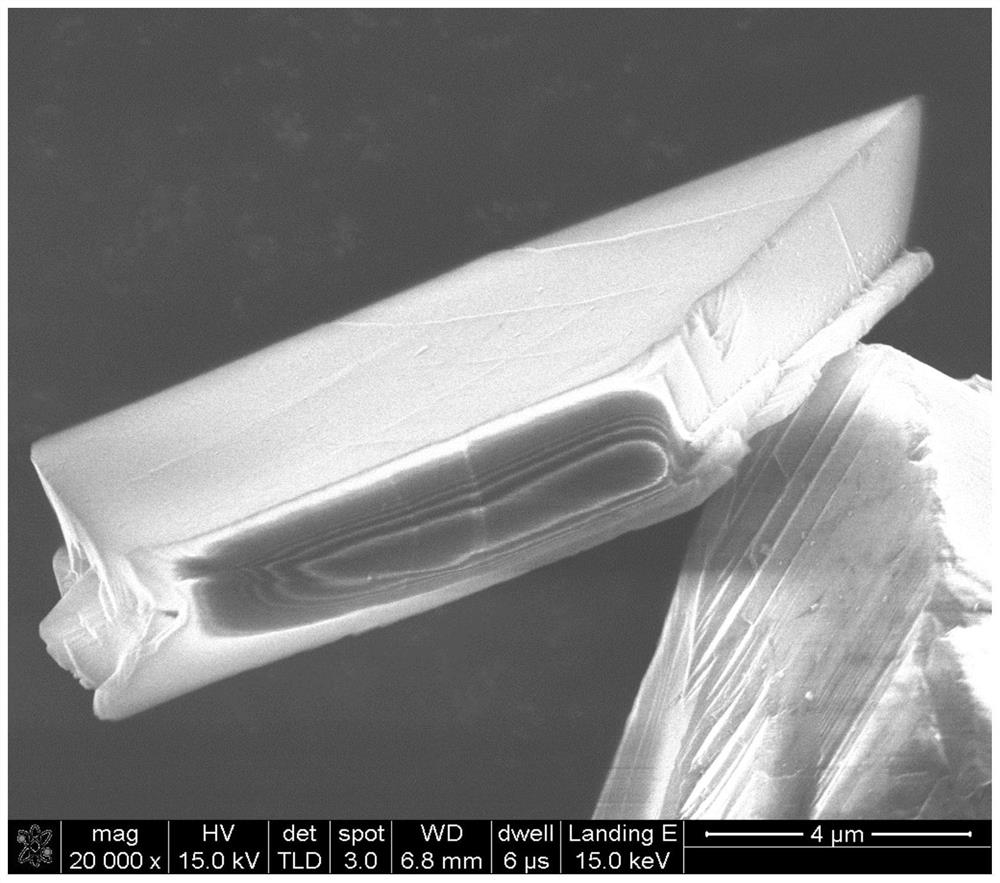

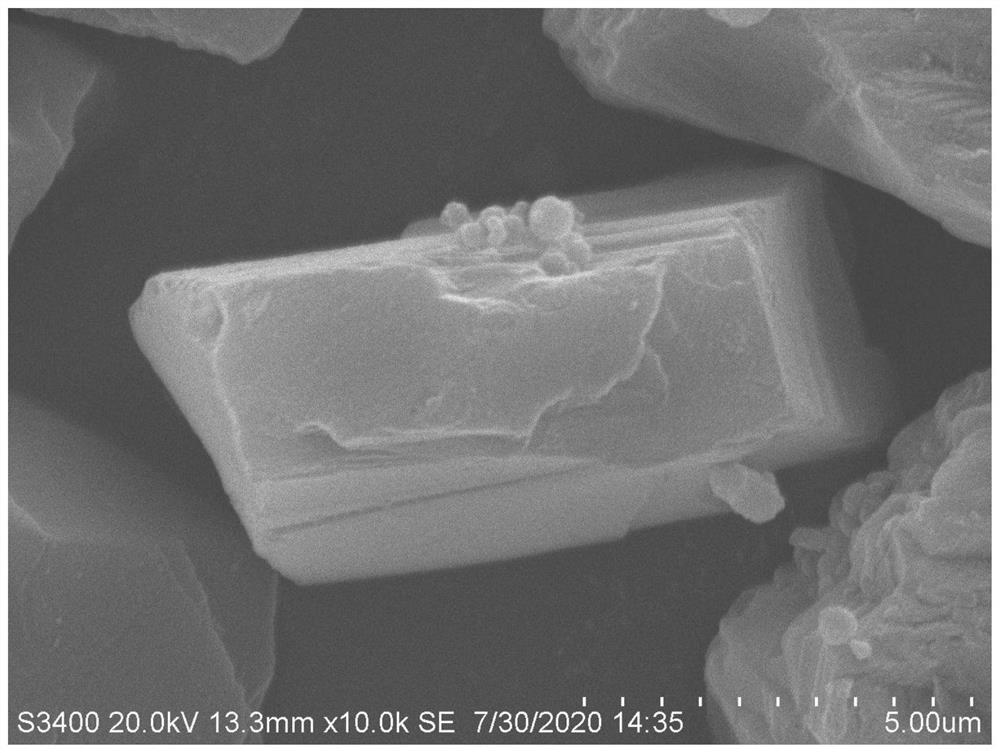

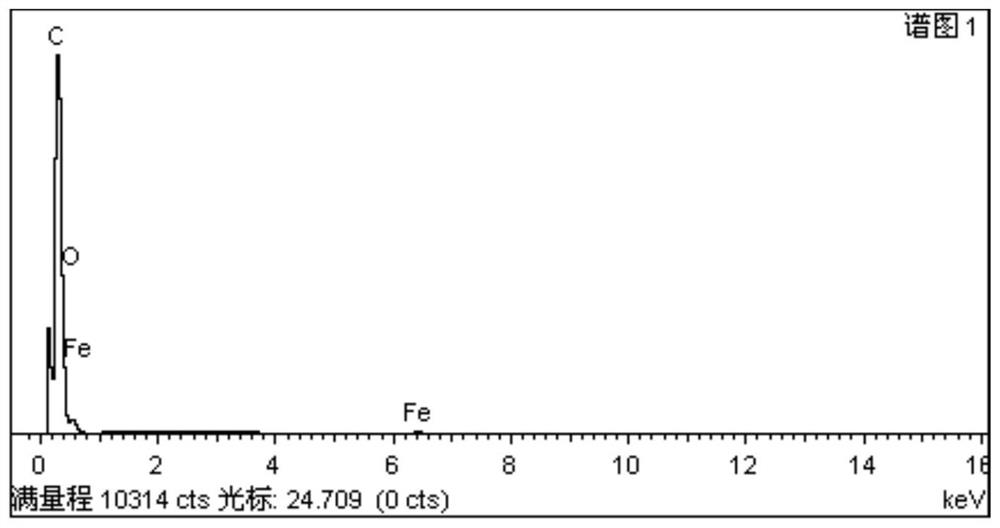

[0043] According to Document 1, in Document 1, Fe was synthesized by adding NaAC 3 o 4 Microspheres, simple optimization is carried out in this embodiment, no reactant such as NaAC is needed, and Fe 3 o 4 The microspheres are coated on the diamond surface, and the specific implementation steps are: FeCl 3 ·6H 2 O and oleic acid (according to every milliliter of oleic acid add 30mg FeCl 3 ·6H 2 O ratio), add 18ml ethanol after fully dissolving, after stirring at room temperature, add 250mg diamond (diamond and FeCl 3 ·6H 2 O mass ratio is about 8:1) after stirring for 10 minutes, transfer to the reactor, and react at 140°C for 16h. Gradient cooling at a cooling rate of 20°C / h, 60°C each time, and keep for 0.5h after each cooling down, take out the reactor after dropping to 25-30°C, filter, and wash with ethanol and deionized water in turn , after drying, the test obtained coated Fe 3 o 4 Microspheres of diamond samples.

[0044] The above literature 1 is Xi G, Yue B,...

Embodiment b

[0046] FeCl 3 ·6H 2 O and oleic acid (according to every milliliter of oleic acid add 70mg FeCl 3 ·6H 2 O ratio), add 18ml ethanol after fully dissolving, after stirring at room temperature, add 250mg diamond (diamond and FeCl 3 ·6H 2 O mass ratio is 3.5:1), stirred for 10 minutes, transferred to the reactor, and reacted at 180°C for 16h. Carry out gradient cooling at a cooling rate of 20°C / h, 60°C each time, and keep it for 0.5h after each drop to 25-30°C, take out the reactor after cooling, filter, and wash with ethanol in turn, remove After washing with ion water and drying, the coated Fe 3 o 4 Microspheres of diamond samples.

Embodiment c

[0048] FeCl 3 ·6H 2 O and oleic acid (according to every milliliter of oleic acid add 50mg FeCl 3 ·6H 2 O ratio), after fully dissolving, add 18ml ethanol, after stirring at room temperature, add 150mg diamond (diamond and FeCl 3 ·6H 2 O mass ratio is 3:1) after stirring for 10 minutes, transferred to the reactor, and reacted at 180°C for 16h. Carry out gradient cooling at a cooling rate of 20°C / h, 60°C each time, and keep it for 0.5h after each drop to 25-30°C, take out the reactor after cooling, filter, and wash with ethanol in turn, remove After washing with ion water and drying, the coated Fe 3 o 4 Microspheres of diamond samples, while Fe 3 o 4 The coating rate of the microspheres on the diamond surface is less than 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com