Preparation method of high-strength curved curtain wall glass

A high-strength, curved surface technology, applied in glass manufacturing equipment, glass forming, glass re-molding, etc., can solve the problem that waste glass cannot be recycled, can not effectively solve the problem of waste glass reuse, etc., to improve clarity and quality. Compressive strength, increasing strength and toughness, reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

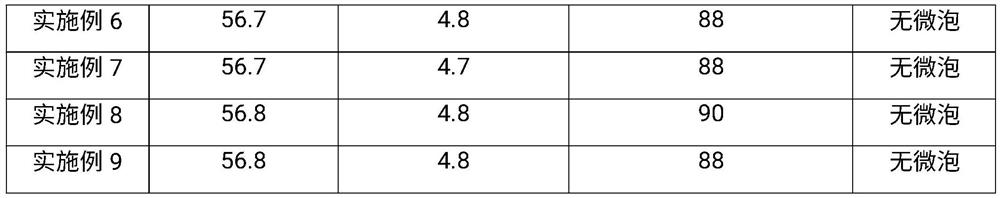

Examples

preparation example 1

[0068] A sheet of glass comprising the following weights of raw material:

[0069] Silicon dioxide: 80 parts;

[0070] Waste glass: 70kg;

[0071] Magnesium oxide: 34kg;

[0072] Calcite: 28kg;

[0073] Glauber's salt: 12kg;

[0074] Reducing agent: 1.6kg;

[0075] Alumina: 19kg;

[0076] Cryolite: 3kg;

[0077] Zirconia: 10kg;

[0078] Boron oxide: 24kg;

[0079] Wherein, reducing agent is tartaric acid.

[0080] The preparation method of above-mentioned glass sheet, comprises the steps:

[0081] S01. Clean the waste glass with water, break it into granules, dry it at 55°C, and then send it to a vacuum tumbler for 90 minutes. After tumbling, the glass particles are cleaned and dried, and the drying temperature is controlled at 55°C. ;

[0082] S02, put glass particles, magnesia, calcite, alumina, cryolite, zirconia and boron oxide into a ball mill for ball milling for 5 hours, and grind into powder;

[0083] S03. Mix Glauber's salt and tartaric acid in advance, an...

preparation example 2

[0086] A sheet of glass comprising the following weights of raw material:

[0087] Silicon dioxide: 96 parts;

[0088] Waste glass: 95kg;

[0089] Magnesium oxide: 29kg;

[0090] Calcite: 19kg;

[0091] Glauber's salt: 14kg;

[0092] Reducing agent: 1.9kg;

[0093] Alumina: 18kg;

[0094] Cryolite: 5kg;

[0095] Zirconium dioxide: 5kg;

[0096] Boron oxide: 28kg;

[0097] Wherein, reducing agent is tartaric acid.

[0098] The preparation method of above-mentioned glass sheet, comprises the steps:

[0099] S01. Clean the waste glass with water, break it into granules, dry it at 60°C, and send it to a vacuum tumbler for 50 minutes. After tumbling, the glass particles are cleaned and dried, and the drying temperature is controlled at 55°C. ;

[0100] S02. Put glass particles, magnesia, calcite, Glauber's salt, alumina, cryolite, zirconia and boron oxide into a ball mill for ball milling for 5 hours, and grind into powder;

[0101] S03. Mix Glauber's salt and tartaric ...

preparation example 3

[0104] A sheet of glass comprising the following weights of raw material:

[0105] Silicon dioxide: 85 parts;

[0106] Waste glass: 85kg;

[0107] Magnesium oxide: 25kg;

[0108] Calcite: 24kg;

[0109] Glauber's salt: 8kg;

[0110] Reducing agent: 2.4kg;

[0111] Alumina: 21kg;

[0112] Cryolite: 6kg;

[0113] Zirconia: 8kg;

[0114] Boron oxide: 30kg;

[0115] Wherein, reducing agent is tartaric acid.

[0116] The preparation method of above-mentioned glass sheet, comprises the steps:

[0117] S01. Clean the waste glass with water, break it into granules, dry it at 55°C, and then send it to a vacuum tumbler for 80 minutes. After tumbling, the glass particles are cleaned and dried, and the drying temperature is controlled at 60°C. ;

[0118] S02, putting glass particles, magnesia, calcite, Glauber's salt, alumina, cryolite, zirconia and boron oxide into a ball mill for ball milling for 6 hours, and grinding into powder;

[0119] S03. Mix Glauber's salt and tartari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com