Method for synthesizing N-methylmorpholine-N-oxide (NMMO) through catalytic oxidation

A technology of methyl morpholine oxidation and catalytic oxidation, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as many side reactions, more waste water, difficult storage and transportation, etc., and achieve easy Separation and purification, ease of reaction conditions, convenient transportation and storage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

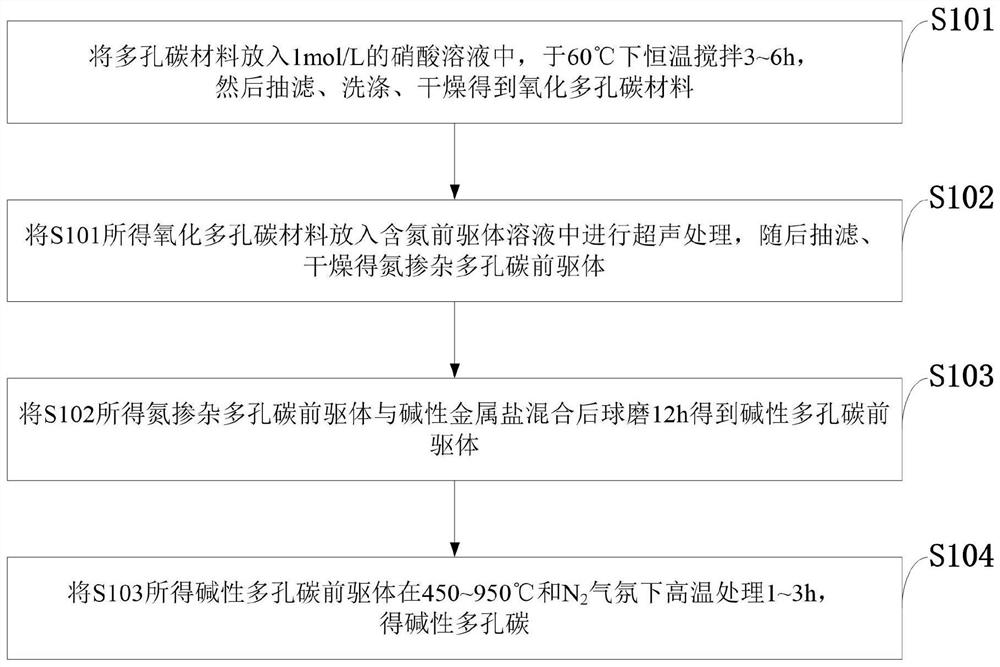

[0030] Such as figure 1 As shown, the preparation method steps of the basic porous carbon catalyst provided by the embodiments of the present invention are as follows:

[0031] S101, put the porous carbon material into a 1 mol / L nitric acid solution, stir at 60° C. for 3-6 hours at a constant temperature, then suction filter, wash, and dry to obtain the oxidized porous carbon material.

[0032] S102, putting the oxidized porous carbon material obtained in S101 into a nitrogen-containing precursor solution for ultrasonic treatment, followed by suction filtration and drying to obtain a nitrogen-doped porous carbon precursor.

[0033] S103, mixing the nitrogen-doped porous carbon precursor obtained in S102 with the basic metal salt and ball milling for 12 hours to obtain the basic porous carbon precursor.

[0034] S104, the basic porous carbon precursor obtained in S103 is heated at 450-950 ° C and N 2 High-temperature treatment under atmosphere for 1-3 hours to obtain basic po...

Embodiment 1

[0037] The embodiment of the present invention provides a method for synthesizing N-methylmorpholine oxide based on nitrogen-doped porous carbon modified by basic metals to catalyze persulfate oxidation. The specific steps are as follows:

[0038]Put activated carbon into 1mol / L nitric acid solution, stir at 60°C for 3 hours, then suction filter, wash, and dry to obtain oxidized activated carbon materials; put the obtained oxidized activated carbon materials into cyanamide solution for ultrasonic treatment, and oxidize The mass ratios of activated carbon to cyanamide were 100:0, 100:5, 100:10, 100:15, and 100:20, respectively, followed by suction filtration and drying to obtain five nitrogen-doped activated carbon precursors with different nitrogen contents; The five nitrogen-doped activated carbon precursors obtained with MgCl 2 After mixing, ball mill for 12h, in which the nitrogen-doped activated carbon precursor was mixed with MgCl 2 The mass ratio is 100:5; the mixture o...

Embodiment 2

[0044] A preferred embodiment of the present invention provides a method for synthesizing N-methylmorpholine oxide based on nitrogen-doped porous carbon modified by basic metals to catalyze persulfate oxidation. The specific steps are as follows:

[0045] Put graphene into 1mol / L nitric acid solution, stir at 60°C for 4 hours, then filter, wash, and dry to obtain graphene oxide material; put the obtained graphene oxide material into cyanamide solution for ultrasonic treatment , wherein the mass ratio of graphene oxide and dicyandiamide is 100:20, followed by suction filtration and drying to obtain a doped graphene precursor; the resulting nitrogen-doped graphene precursor and AlCl 3 After mixing, ball mill for 12h, in which graphene oxide and AlCl 3 The mass ratios are 100:0, 100:5, 100:10, 100:15 and 100:20 respectively; 2 Treated under atmosphere to obtain 5 kinds of basic porous carbons.

[0046] Under the conditions of normal pressure, 70°C and catalyst dosage of 2wt% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com