Preparation method of high-purity micafungin precursor FR901379

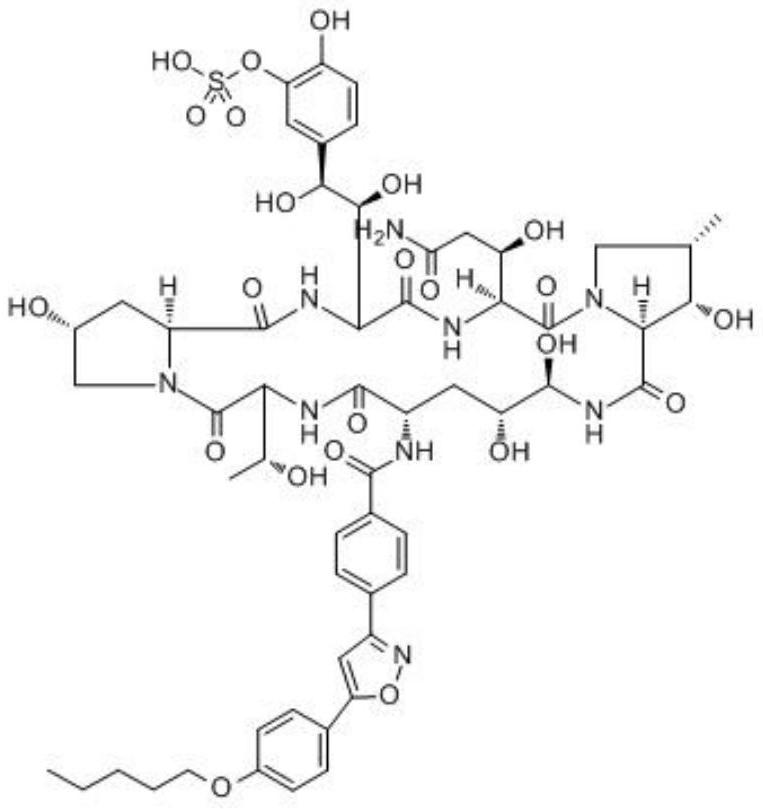

A technology of FR901379 and micafungin, applied in the field of preparation of high-purity micafungin precursor FR901379, achieves the effects of easy solvent recovery, high quality and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

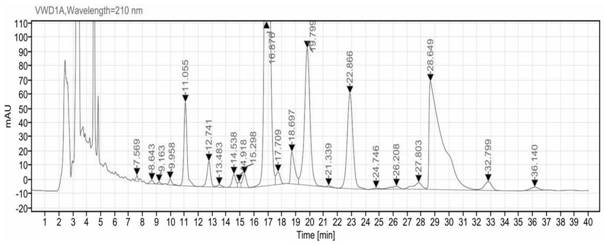

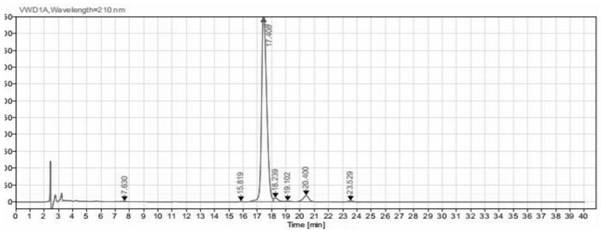

Image

Examples

Embodiment 1

[0030] S1 took 20L of micafungin precursor FR901379 fermentation broth, the fermentation unit was 0.835mg / mL, added filter aid and plate and frame pressure filtration, and obtained 5.3kg of micafungin precursor fermentation broth bacterial residue;

[0031] Add 10L of 95% ethanol to S2, stir for 2 hours, and collect the filtrate by pressure filtration with a plate frame again to obtain the micafungin precursor extract;

[0032] S3 uses a 50 nanometer ceramic membrane to filter the extraction solution and collect the dialysate;

[0033] S4 Add water to the dialysate to adjust the ethanol concentration to 30%, absorb with 5.0 LPAD900 resin, rinse with 10.0L 50% ethanol solution, elute with 95% ethanol, and concentrate under reduced pressure at 40°C until there is no liquid in the condenser after elution outflow;

[0034] S5 Add 1000mL ethyl acetate to the concentrated solution to extract and concentrate;

[0035] S6 Add 700mL of 70% acetone solution to the extract concentrate,...

Embodiment 2

[0042] S1 Take 30L of micafungin precursor FR901379 fermentation broth, the fermentation unit is 0.925mg / mL, add filter aid and plate and frame filter to obtain 8.6kg of micafungin precursor fermentation broth, add 15L of 90% methanol, stir for 1h, Use plate and frame to press filter again to collect the filtrate; use 100 nanometer ceramic membrane to filter the leachate to collect the dialysate.

[0043] S2 Add water to the dialysate to adjust the methanol concentration to 30%, adsorb with 8.0LD1300 resin, wash with 15.0L 50% methanol solution, elute with 90% methanol, and concentrate under reduced pressure at 40°C until there is no liquid in the condenser flow out.

[0044] S3 Add 1500 mL of butyl acetate to the concentrated solution for extraction and concentrate.

[0045] S4 Add 1000mL of 60% diethyl ether solution to the concentrated extraction solution, stir for 30min, then let it stand for 2h, filter and dry with suction to obtain 28.4g of the crude precursor of FR9013...

Embodiment 3

[0050] S1 Take 40L of micafungin precursor FR901379 fermentation broth, the fermentation unit is 0.846mg / mL, add filter aid and plate and frame filter to obtain 11.2kg of micafungin precursor fermentation broth, add 20L of 80% ethanol, stir for 2h, The filtrate was collected by press filtration again with a plate frame; the leaching solution was filtered with a 50 nanometer ceramic membrane to collect the dialysate.

[0051] S2 Add water to the dialysate to adjust the ethanol concentration to 30%, absorb with 12.0L LPAD900 resin, rinse with 15.0L 50% ethanol solution, elute with 80% ethanol, and concentrate under reduced pressure at 40°C until there is no liquid in the condenser flow out.

[0052] S3 Add 2000mL n-hexane to the concentrated solution for extraction and concentrate.

[0053] S4 Add 900mL of 60% acetone solution to the concentrated extraction solution, stir for 30min, then let it stand for 2h, filter and dry to obtain 34.3g of FR901379 micafungin precursor crude ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com