High-conductivity film phase change material for thermal battery, preparation method and application

A phase-change material, high-conductivity technology, used in primary battery use/maintenance, heat exchange materials, battery cooling/heating, etc., can solve problems such as battery temperature runaway, battery internal pressure increase, battery explosion, etc. Cost of fabrication, enhanced conductivity, reduced complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

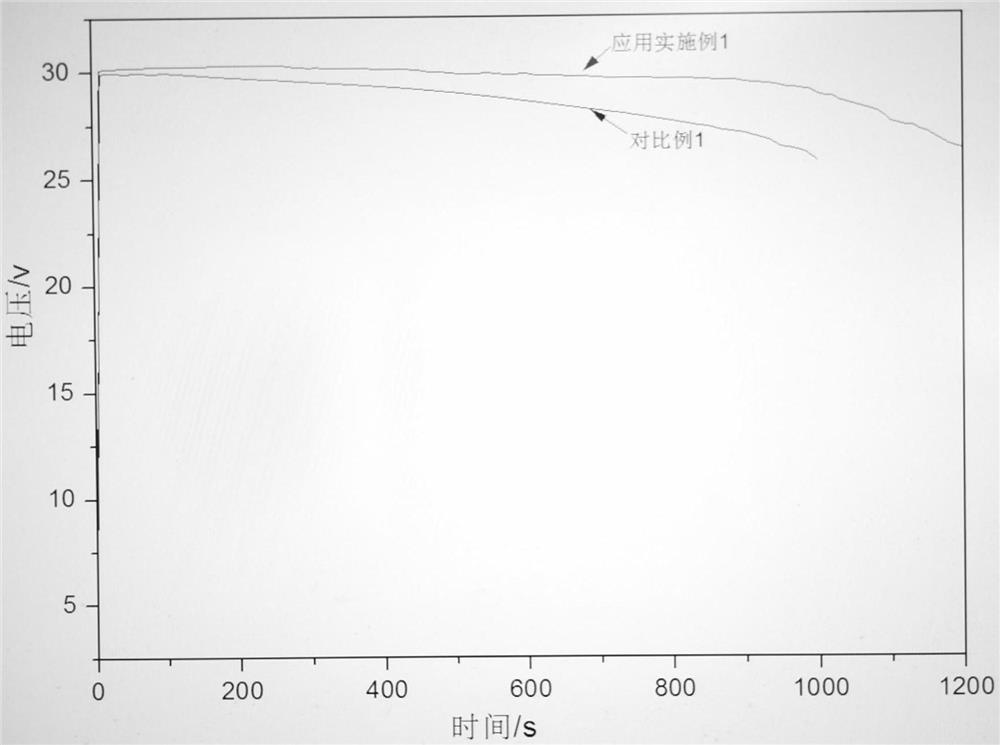

Examples

Embodiment 1

[0032] A method for preparing a high-conductivity thin-film phase-change material for a thermal battery. The raw material is composed of an easily soluble inorganic salt, a high-conductivity conductive agent, an adhesive, an adsorbent and a matrix film. The preparation method comprises the following steps:

[0033] Step 1: Weigh 31.5 parts of NaCl and 38.5 parts of KCl into a beaker, add deionized water to prepare a supersaturated solution, in which the mass of solute and the mass of deionized water are prepared according to 1:1~1.2, and then add 3.0 1 part of sodium hydroxymethylcellulose (CMC) and 3.0 parts of styrene-butadiene rubber (SBR) adhesive, stirring constantly, the number of revolutions of the agitator is 900r / min, and the stirring time is 2.5h;

[0034] Step 2: Add 25 parts of graphene conductive agent and 3 parts of MgO adsorbent to step 1 and fully stir, the rotation speed of the stirrer is 500r / min, and the stirring time is 4h, to obtain a uniformly mixed phase ...

Embodiment 2

[0038] A method for preparing a high-conductivity thin-film phase-change material for a thermal battery. The raw material is composed of an easily soluble composite inorganic salt, a high-conductivity conductive agent, an adhesive, an adsorbent and a matrix film. The preparation method comprises the following steps:

[0039] Step 1: Weigh 12.0 parts of Li 2 CO 3 , 12.0 parts of Na 2 CO 3 and 36.0 parts K 2 CO 3 Pour parts into a beaker, add deionized water to prepare a supersaturated solution, wherein the mass of solute and the mass of deionized water are prepared according to 1:1~1.2, and then add 2.5 parts of sodium hydroxymethyl cellulose (CMC) and 2.5 parts of aluminum dihydrogen phosphate adhesive, stirring continuously, the rotation speed of the stirrer is 1000r / min, and the stirring time is 5h;

[0040] Step 2: Add 40.0 parts of expanded graphite conductive agent and 6.0 parts of MgO adsorbent to step 1 and stir fully, the rotation speed of the stirrer is 500r / min, a...

Embodiment 3

[0044] A method for preparing a high-conductivity thin-film phase-change material for a thermal battery. The raw material is composed of an easily soluble composite inorganic salt, a high-conductivity conductive agent, an adhesive, an adsorbent and a matrix film. The preparation method comprises the following steps:

[0045] Step 1: Weigh 35.0 parts of Na 2 CO 3 and 35.0 parts K 2 CO 3 Pour one part of easily soluble phase-change inorganic salt into a beaker, add deionized water to prepare a supersaturated solution, in which the mass of solute and the mass of deionized water are prepared according to the ratio of 1:1 to 1.2, and then add 4.0 parts of hydroxymethyl cellulose Sodium plain (CMC) and 2.0 parts of sodium silicate are used as adhesive, stirring continuously, the rotation speed of the stirrer is 1500r / min, and the stirring time is 3h;

[0046] Step 2: Add 30 parts of graphene conductive agent and 3 parts of BN adsorbent to step 1 and fully stir, the rotation speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com