Preparation method of core-shell structure quantum dot and product prepared from core-shell structure quantum dot

A core-shell structure, quantum dot technology, applied in the field of nanomaterial preparation, can solve problems such as gaps, and achieve the effects of improving quality, simplifying the shell coating process, and high fluorescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

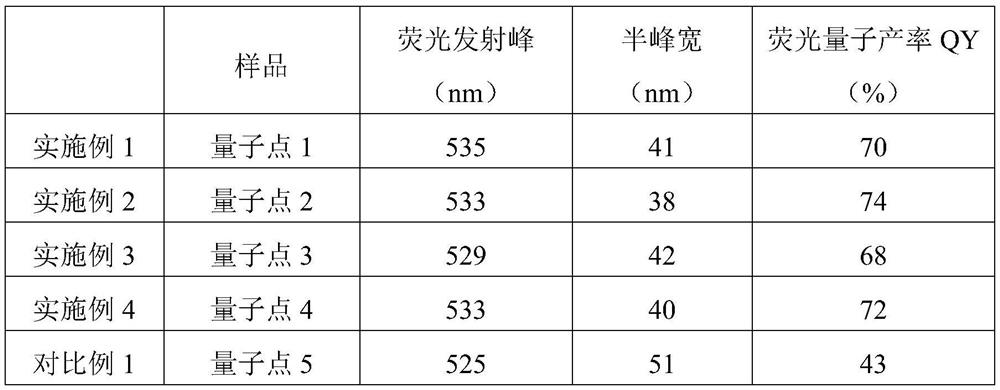

Examples

preparation example Construction

[0026] The application provides a method for preparing quantum dots with a core-shell structure, comprising steps:

[0027] S1. Obtain a first mixed solution containing quantum dots, a second mixed solution containing a cation precursor, and an anion precursor;

[0028] S2. At a predetermined temperature, add a second mixed solution containing a cation precursor and an anion precursor to the first mixed solution containing quantum dots, the cation precursor reacts with the anion precursor to form a quantum dot coating shell layer to obtain core-shell structure quantum dots;

[0029] Wherein, the second mixed solution containing the cation precursor includes the cation precursor and an organic solvent for dispersing the cation precursor, and the boiling point of the organic solvent is lower than the predetermined temperature.

[0030] According to a preferred embodiment of the present application, the range of the predetermined temperature is 180-320°C, and the boiling point o...

Embodiment approach

[0036] According to a preferred embodiment of the present application, the cationic precursor is an organozinc precursor.

[0037] In a specific embodiment, the cationic precursors include zinc carboxylate, zinc dimethyl, zinc diethyl, zinc acetylacetonate, zinc stearate, zinc oleate, zinc dedecanoate, zinc undecylenate, Zinc Tetralate, Zinc Palmate, Zinc Ethylxanthate, Zinc Propylxanthate, Zinc Cetylxanthate, Zinc Diethyldithiocarbamate, Ethylphenyldithioamino At least one of zinc formate, zinc methylphenyl dithiocarbamate, and zinc di-n-butyldithiocarbamate.

[0038] In the prior art, the solubility of the cation precursor required for the synthesis of the shell is usually not good. Such as the conventional method to synthesize ZnS or ZnSe shell required precursor material - zinc source (mixing zinc stearate with oleic acid or oleylamine or octadecene, etc., and reacting under heating conditions, the preparation process is time-consuming and difficult to operate. Complex),...

Embodiment 1

[0060] Preparation of core-shell quantum dots 1:

[0061] S1. Obtain the first mixed solution containing InP quantum dots:

[0062] Under an inert gas atmosphere, make 1mmol In(OAc) 3 , 3mmol oleic acid, 20mL octadecene, and 1mmol tris(trimethylsilyl)phosphine were mixed, heated and reacted to obtain the first mixed solution comprising InP quantum dots;

[0063] S2. Obtaining the second mixed solution containing zinc stearate:

[0064] Make 4mmol zinc stearate, 8mL toluene mix, heat reaction, obtain the second mixed liquor that comprises zinc stearate;

[0065] S3, coating the ZnS shell layer for InP quantum dots:

[0066] At 240°C, add the second mixed solution containing zinc stearate in step S2 to the first mixed solution containing InP quantum dots in step S1, and then add 4 mmol sulfur tri-n-octylphosphine solution to the reaction system, After heating and reacting for 2 hours, a core-shell quantum dot 1 covered with a ZnS shell layer was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com