Production method and production device of silicon carbide single crystal

A silicon carbide single crystal, manufacturing device technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems such as wafer cracks, SiC single crystal ingot cracks, cracks, etc., to suppress cracks or cracks , the effect of small residual strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Hereinafter, although an Example and a comparative example are shown and this invention is demonstrated more concretely, this invention is not limited to these.

[0062] (Example)

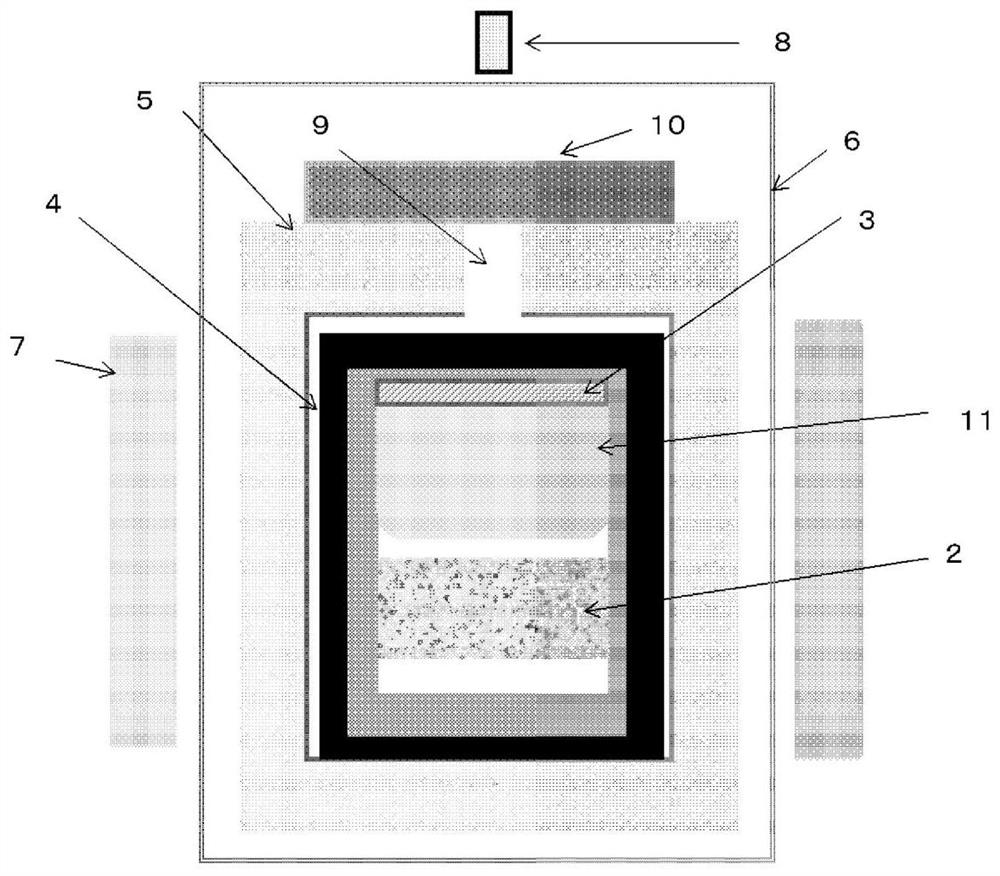

[0063] According to the manufacturing method of silicon carbide single crystal of the present invention, using figure 2 The silicon carbide single crystal manufacturing apparatus 1 shown grows a SiC single crystal having a diameter of 4 inches (100 mm) under the following growth conditions.

[0064]

[0065] Seed crystal substrate···SiC single crystal substrate with a diameter of 4 inches (100mm) whose main surface is inclined 4° from the {0001} plane to the direction

[0066] Growth temperature...2200℃

[0067] Pressure···10Torr(1.3×10hPa)

[0068] Atmosphere...Argon, Nitrogen

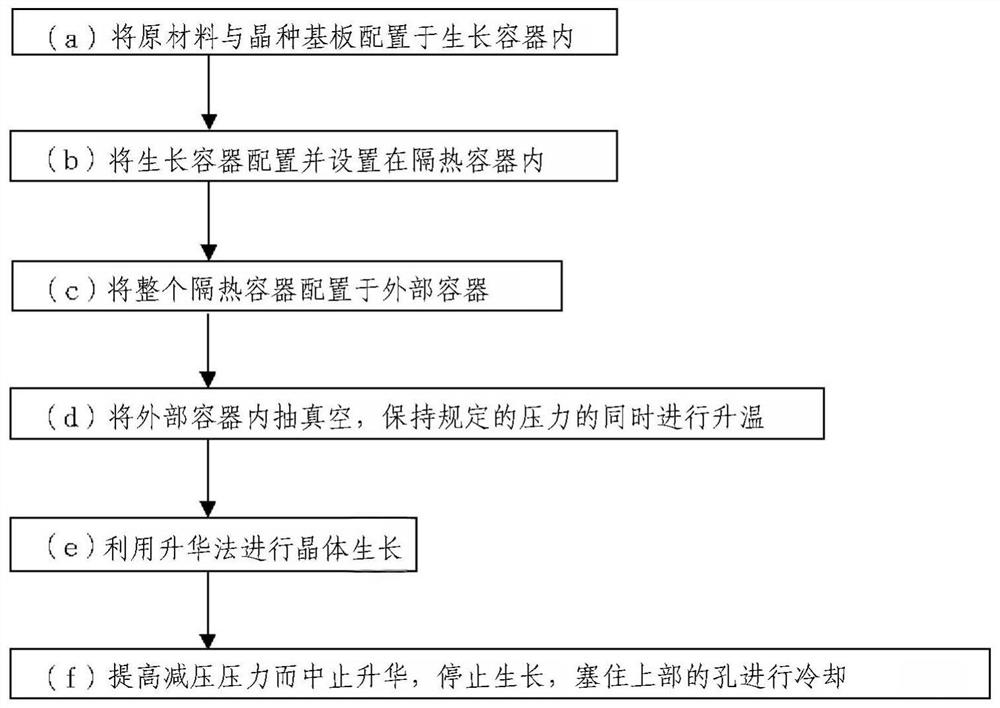

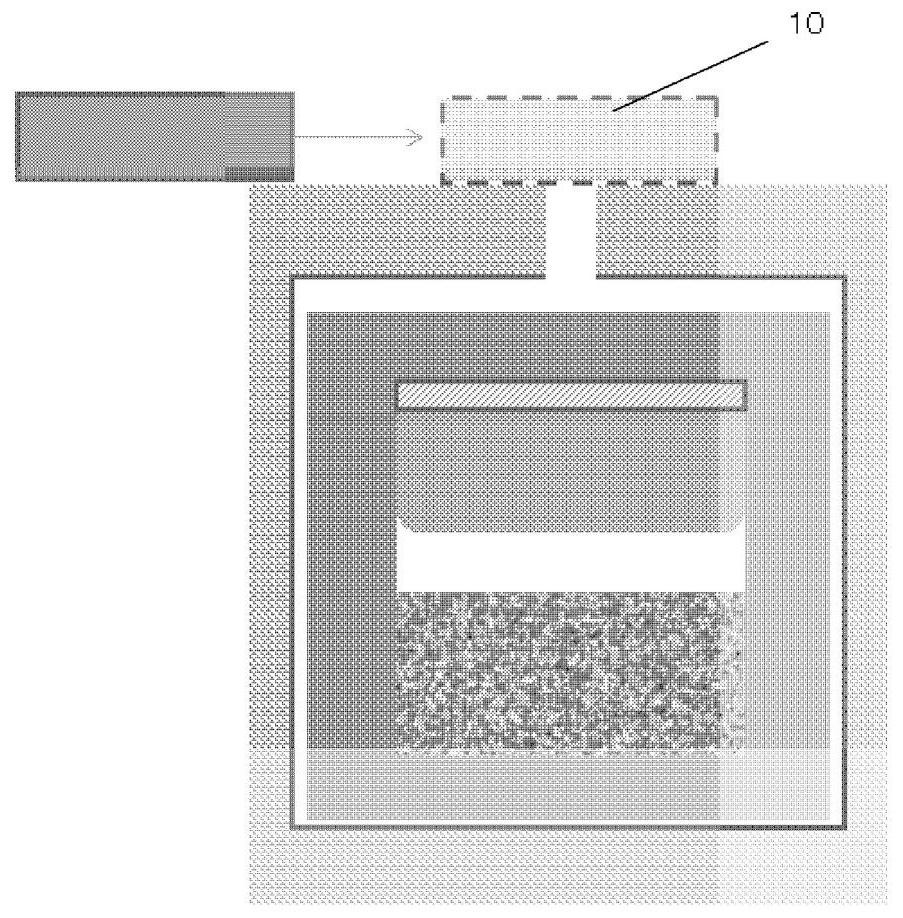

[0069] according to figure 1 In the procedure shown, when the grown SiC single crystal is cooled, the hole 9 for temperature measurement is closed with the shielding member 10, and five SiC single crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com