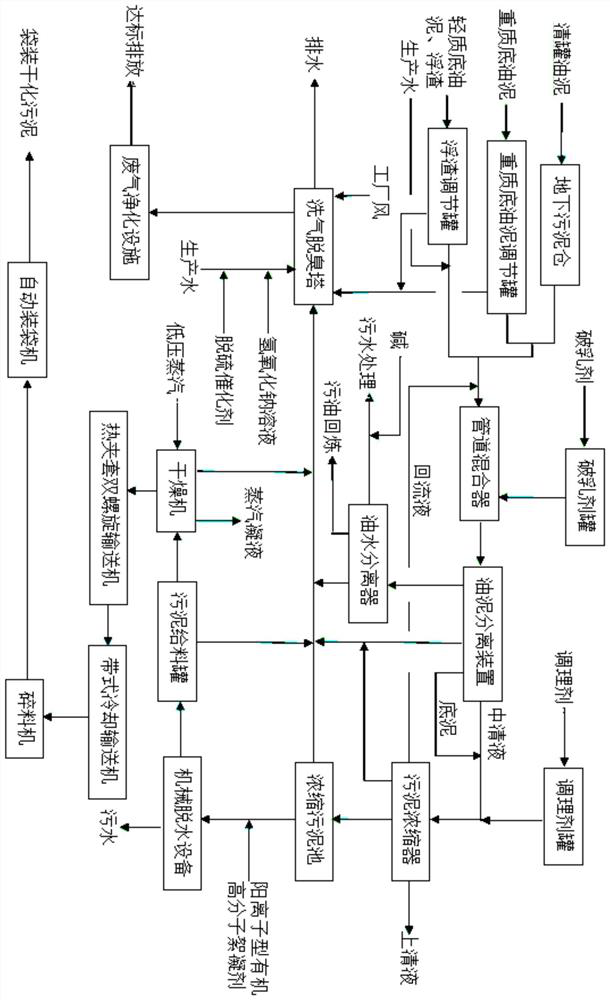

Oily sludge treatment method suitable for heavy bottom oil sludge and tank cleaning oil sludge

A technology of oil sludge and bottom oil, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Problems such as high rate, equipment not working properly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

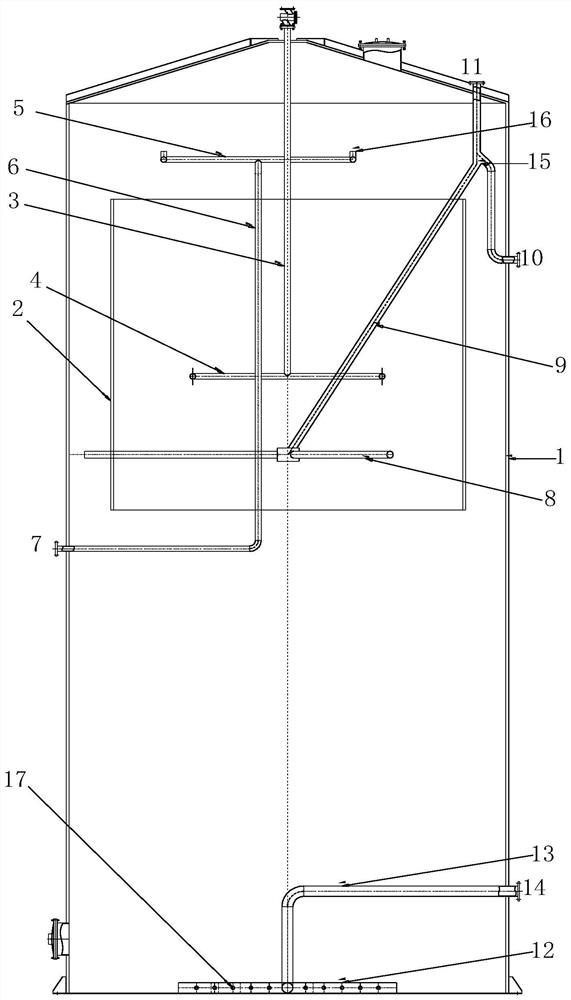

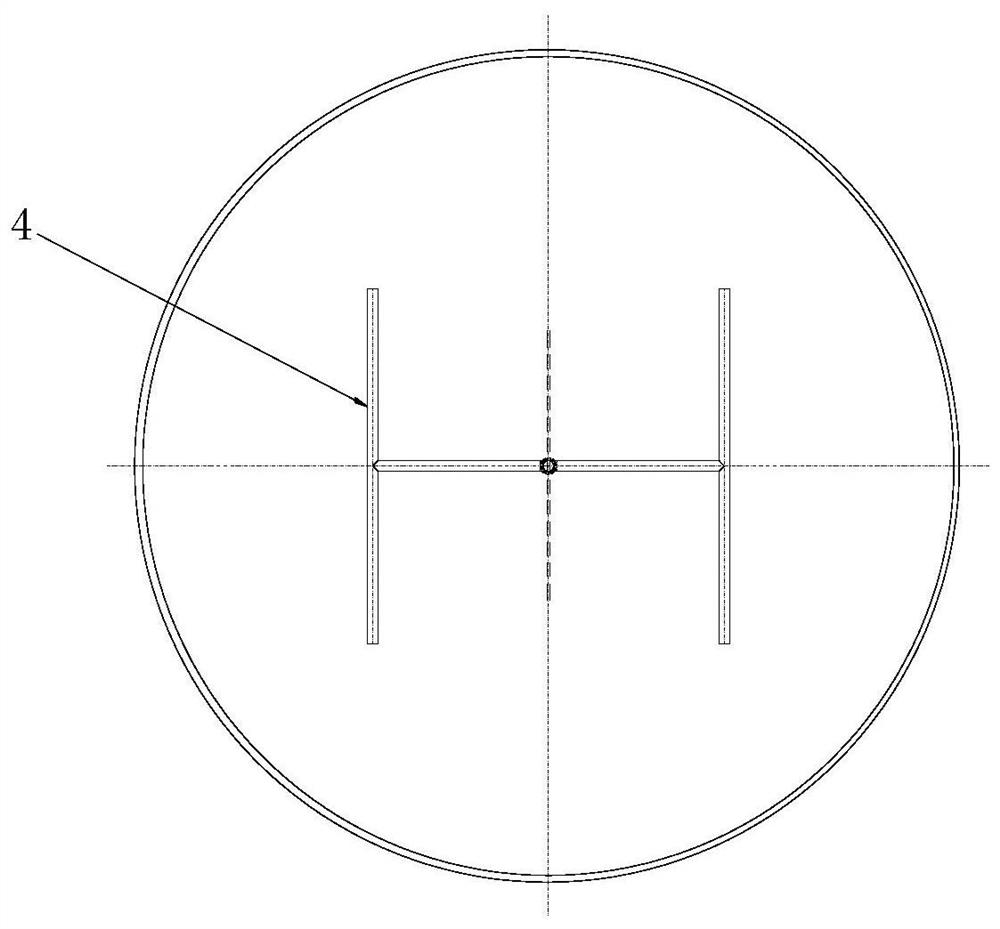

Image

Examples

Embodiment 1

[0078] Add 10m in the heavy bottom oil sludge regulating tank of embodiment 1 3 Heavy bottom sludge S 1 , S 1 ’, add 15m in the scum regulating tank 3 Scum S 2 , the temperature in the two adjustment tanks is maintained at 40°C by means of steam coils, which are transported to the oil sludge separation device through pumps respectively, and 98% concentrated sulfuric acid is added at the same time, and the pH of the oil sludge separation device is adjusted to 1.5. After the acid is stopped, the oil sludge separation device Set up heat preservation, stand and separate at 40°C for 72 hours.

[0079] The recovered waste oil S is extracted from the upper part of the sludge separation device 0 , and then discharge all the middle clear liquid and lower bottom sludge of the oil sludge separation device into the sludge concentrator and then sample S 3 , S 3 ’, add 30% sodium hydroxide solution in the sludge concentrator to adjust the pH to 7, the S 0 , S 1 , S 2 , S 3 Carry o...

Embodiment 2

[0096] The bottom sludge of a crude oil tank area of a petrochemical enterprise was taken. According to laboratory analysis, the solid content of the bottom sludge was 8.21%, the oil content was 31.65% (light oil content was 5.34%), and the water content was 60.14%. Put 200 g of this bottom sludge into a 1000 mL separatory funnel, then add 400 mL of distilled water to the separatory funnel, add 98% sulfuric acid to the separatory funnel, and adjust the pH to 2 after shaking well. Put the separatory funnel in a 40°C water bath at a constant temperature for 72 hours, discharge all the mud-water mixture in the lower part of the separatory funnel into the measuring cylinder, measure the total volume of the mud-water mixture to be 580mL, and analyze and determine its light oil content to be 0.16%. Therefore, the light oil recovery rate is: (200×5.34%-580×0.16%) / (200×5.34%)=91.31%.

Embodiment 3

[0098] The oil sludge from a petrochemical enterprise was taken, and the solid content of the oil sludge was 25.7%, the oil content was 30% (the light oil content was 4.86%), and the water content was 44.3%. Put 200 g of the clear tank sludge into a 1000 mL separatory funnel, then add 400 mL of distilled water into the separatory funnel, add 98% sulfuric acid into the separatory funnel, shake well and adjust the pH to 2. Put the separatory funnel in a 40°C water bath at a constant temperature for 72 hours, then discharge all the mud-water mixture in the lower part of the separatory funnel into the measuring cylinder, and measure the total volume of the mud-water mixture to be 583mL, and analyze and determine that the light oil content is 0.12%. Therefore, the light oil recovery rate is: (200×4.86%-583×0.12%) / (200×4.86%)=92.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com