Modified polyacrylamide and preparation method thereof, and polymer slurry

A technology of polyacrylamide and acrylamide, which is applied in the field of pile foundation retaining wall materials, can solve the problems that general products cannot play a good role, do not have high salinity geological research, and reduce viscosity, so as to improve salt resistance and shear resistance Performance, hole size uniformity, and the effect of increasing the electronic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The first aspect of the present invention discloses a preparation method of modified polyacrylamide, comprising the following steps:

[0031] dissolving the emulsifier, sodium α-alkenyl sulfonate and acrylamide in deionized water, mixing, stirring and dispersing to obtain the first solution in the state of emulsion;

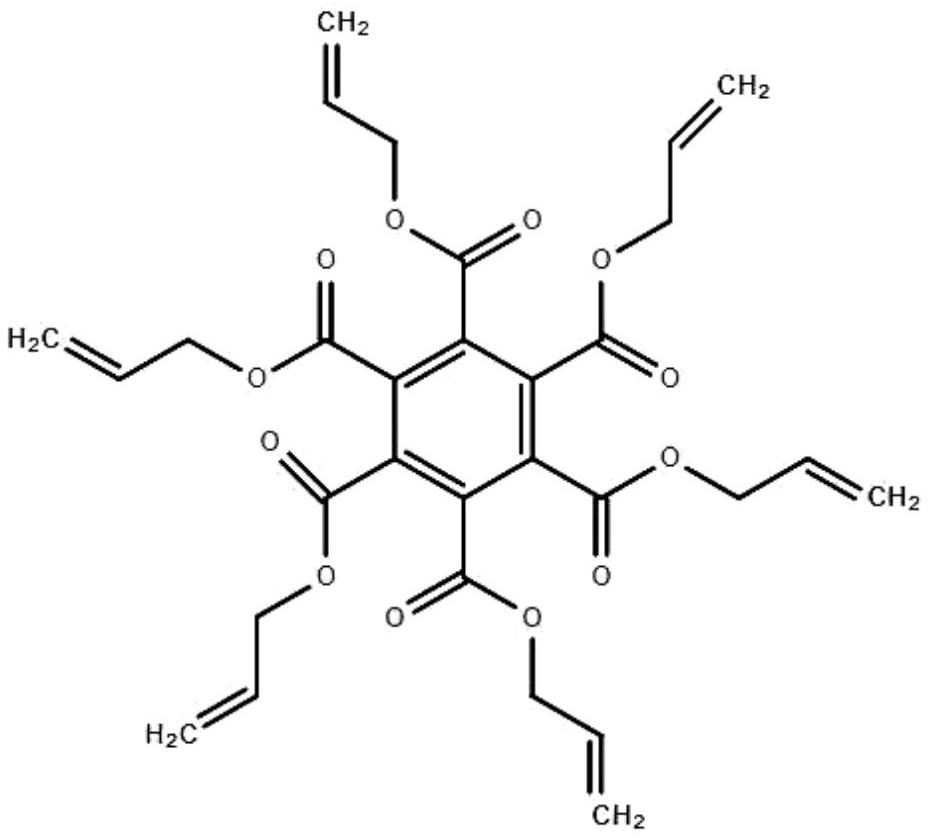

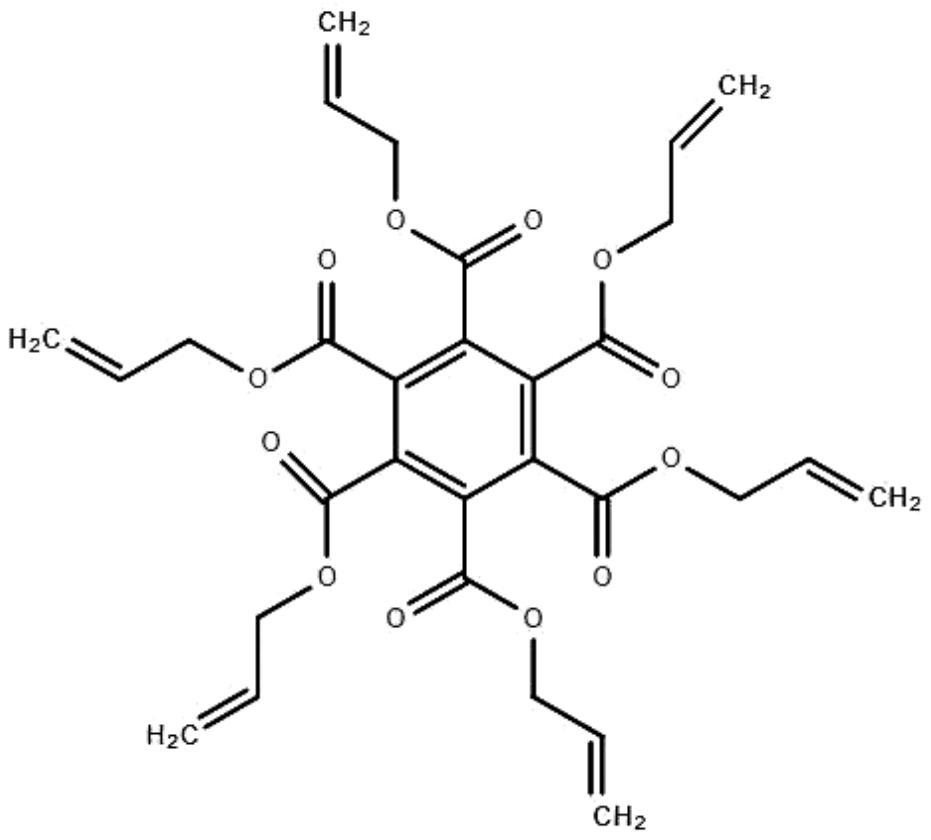

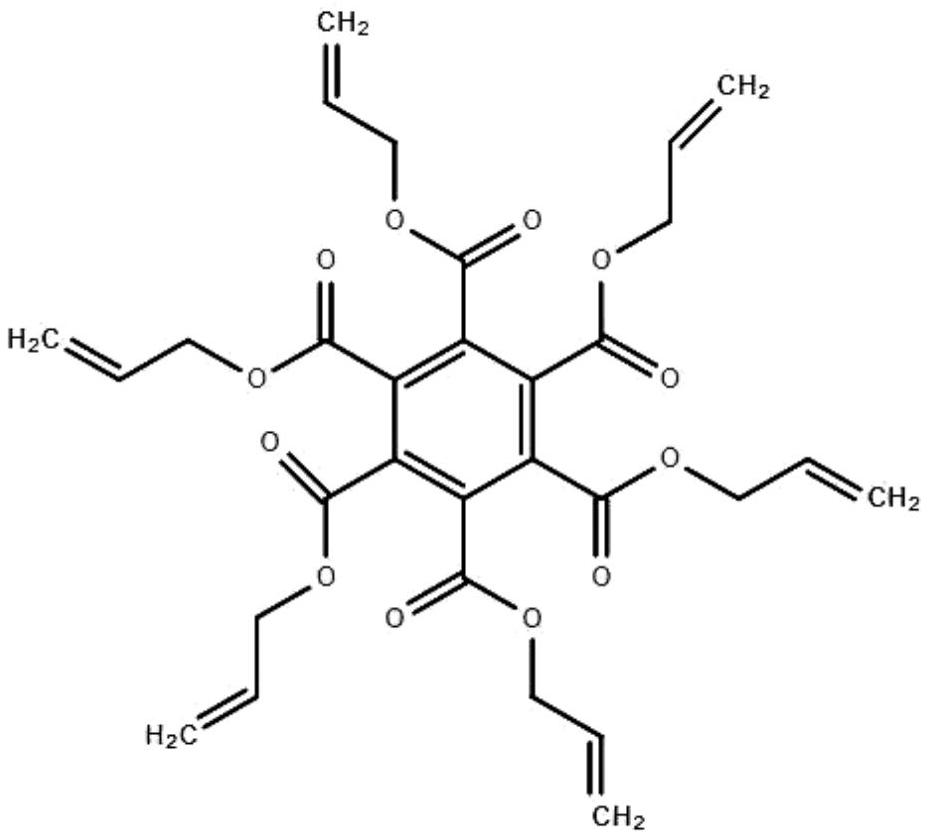

[0032] dissolving allyl mellitic acid ester in deionized water to obtain a second solution;

[0033] The initiator is dissolved in deionized water to obtain a third solution;

[0034] The hydrophobic monomer and acrylic acid are dissolved in deionized water to obtain a fourth solution;

[0035] After the first solution is deoxygenated, the second solution is added dropwise to it, and the temperature is raised to 60-65°C; the third solution and the fourth solution are added dropwise to it at the same time, and the reaction is continued for 5-6h, After adjusting the pH of the system to 7-8, continue to stir and react, purify, and obtain modified polyacryla...

Embodiment 1

[0052] Preparation of modified polyacrylamide: Add 12.6 parts of mellitic acid and 45 parts of acryl alcohol into the flask and stir thoroughly, then slowly add 0.29 parts of concentrated sulfuric acid dropwise, heat the mixture to 130°C, and react for 3 hours. After the reaction, neutralize the unreacted sulfuric acid with 3.2 parts of calcium hydroxide, and filter out the precipitate. Finally, the filtrate was concentrated to obtain allyl mellitic acid ester.

[0053] Take 1 part of sodium lauryl sulfate, 0.2 part of sodium α-alkenyl sulfonate, 18 parts of acrylamide, add 71.87 parts of deionized water and mix them, then stir and disperse quickly, so that the solution is in the state of emulsion, and then deoxygenate in nitrogen. Under protection, add 0.6 parts of allyl mellitic acid ester to 10 parts of deionized water to form a solution, slowly add it dropwise into the system, and raise the temperature to 60-65°C, and at the same time add 0.53 parts of potassium persulfate...

Embodiment 2

[0056] Preparation of modified polyacrylamide: Add 12.6 parts of mellitic acid and 40 parts of acrylic alcohol into the flask and stir thoroughly, then slowly add 0.29 parts of concentrated sulfuric acid dropwise, heat the mixture to 130°C, and react for 3 hours. After the reaction, neutralize the unreacted sulfuric acid with 3.2 parts of calcium hydroxide, and filter out the precipitate. Finally, the filtrate was concentrated to obtain allyl mellitic acid ester.

[0057] Take 0.8 parts of sodium lauryl sulfate, 0.16 parts of sodium α-alkenyl sulfonate, 18 parts of acrylamide and add 71.65 parts of deionized water to mix and then stir and disperse quickly to make the solution in an emulsion state, and then pass nitrogen to remove oxygen. Under protection, add 0.72 parts of allyl mellitic acid ester to 10 parts of deionized water to form a solution, slowly add it dropwise into the system, and raise the temperature to 60-65°C, and add dropwise at the same time with a mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com