Method and system for amorphizing metal material by adopting ultrafast pulse laser

An ultrafast laser, metal material technology, applied in the field of metal material amorphization, can solve the problems of inability to achieve rapid heating and rapid cooling, inability to apply a single metal amorphous preparation, inability to process amorphous structures, etc., to achieve optimization. Effects of mechanical properties, improved cooling rate, optimized corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

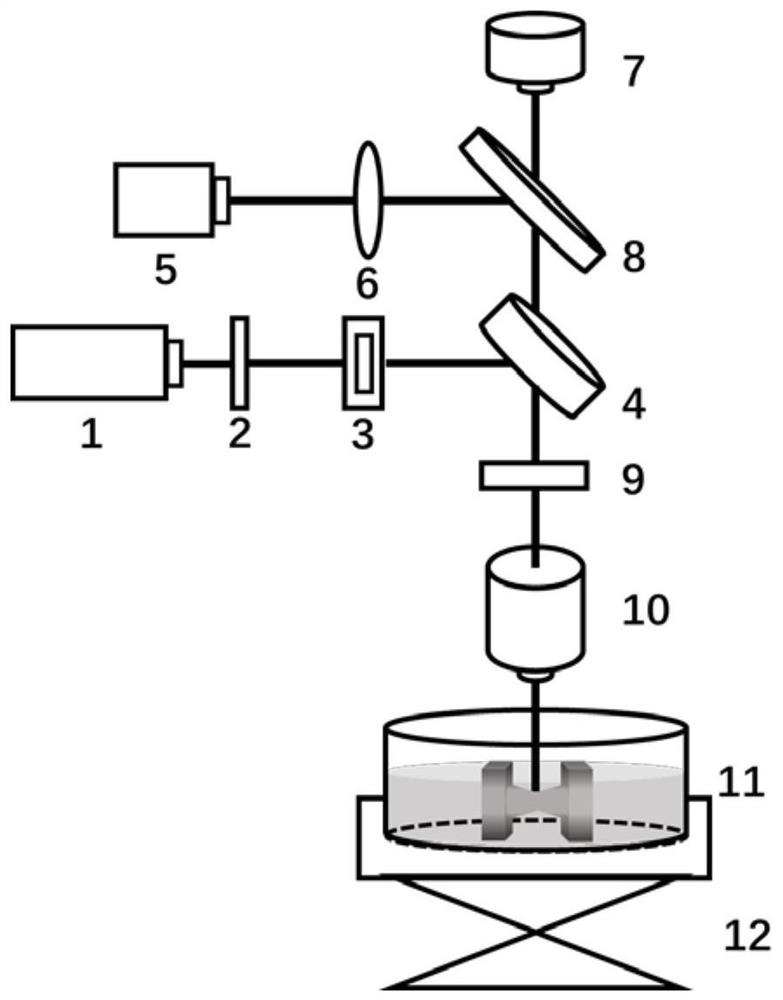

[0033] Adjust the precision attenuation wheel 2, and set the single pulse energy to 6.25J cm -2 , the magnification of the objective lens 10 is 10 times, the numerical aperture is 0.5, and the working distance is 7.77mm. The number of laser pulses irradiated to the metal is controlled by an electronically controlled shutter to be 400, forming an amorphous with a minor axis length of 82nm and a depth of 80nm. metal area.

Embodiment 2

[0035] Adjust the precision attenuation wheel 2, and set the single pulse energy to 7.42J cm -2 , the magnification of the objective lens 10 is 10 times, the numerical aperture is 0.5, and the working distance is 7.77mm. The number of laser pulses irradiated to the metal is controlled by an electronically controlled shutter to be 400, forming an amorphous with a minor axis length of 80nm and a depth of 84nm. metal area.

Embodiment 3

[0037] Adjust the precision attenuation wheel 2, and set the single pulse energy to 6.25J cm -2 , the magnification of the objective lens 10 is 10 times, the numerical aperture is 0.5, and the working distance is 7.77mm. The number of laser pulses irradiated to the metal is controlled by an electronically controlled shutter to be 800, forming an amorphous with a minor axis length of 90nm and a depth of 91nm. metal area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com