Nano deodorant polyurethane synthetic leather and preparation method thereof

A polyurethane and synthetic leather technology, applied in textiles and papermaking, can solve the problems of lack of high tensile strength and elongation at break, mechanical properties that cannot meet the needs of use, poor product air permeability and deodorization, etc. Good antibacterial and deodorant properties, improved air permeability, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

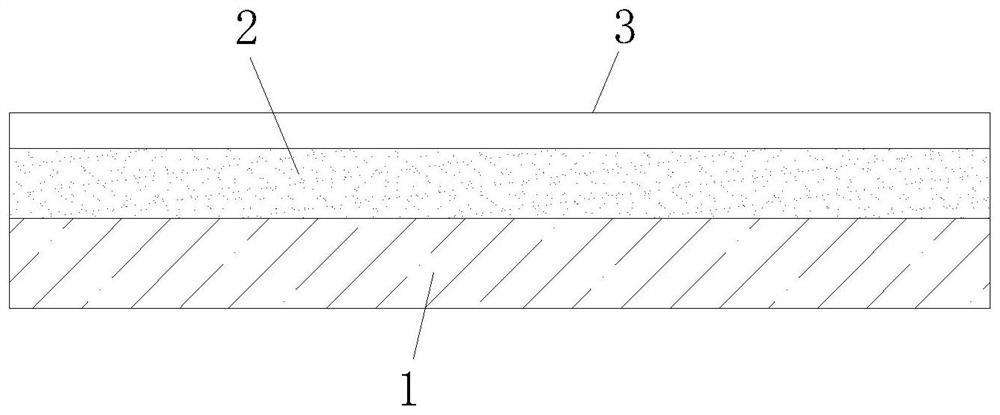

[0025] see figure 1 , the present invention provides the following technical solutions: a nano deodorant polyurethane synthetic leather, comprising nano deodorant polyurethane synthetic leather, the nano deodorant polyurethane synthetic leather is made of pretreatment base cloth 1, water-based polyurethane foamed on the pretreatment base cloth 1 The slurry layer 2 is composed of a halogen-free flame-retardant layer 3 compounded on the water-based polyurethane foam slurry layer 2, and the halogen-free flame-retardant layer 3 is a halogen-free flame-retardant polyether polyurethane coating coated by a release paper film transfer method , to obtain a halogen-free flame-retardant polyurethane film.

[0026] Specifically, the pretreatment base fabric 1 is obtained by impregnating the non-woven fabric in the pretreatment impregnating solution, extruding it through rollers, ironing it with an ironing roller, and drying it.

[0027] In this embodiment, the impregnation solution inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com