A kind of solid oxide fuel cell electrode material and preparation method thereof

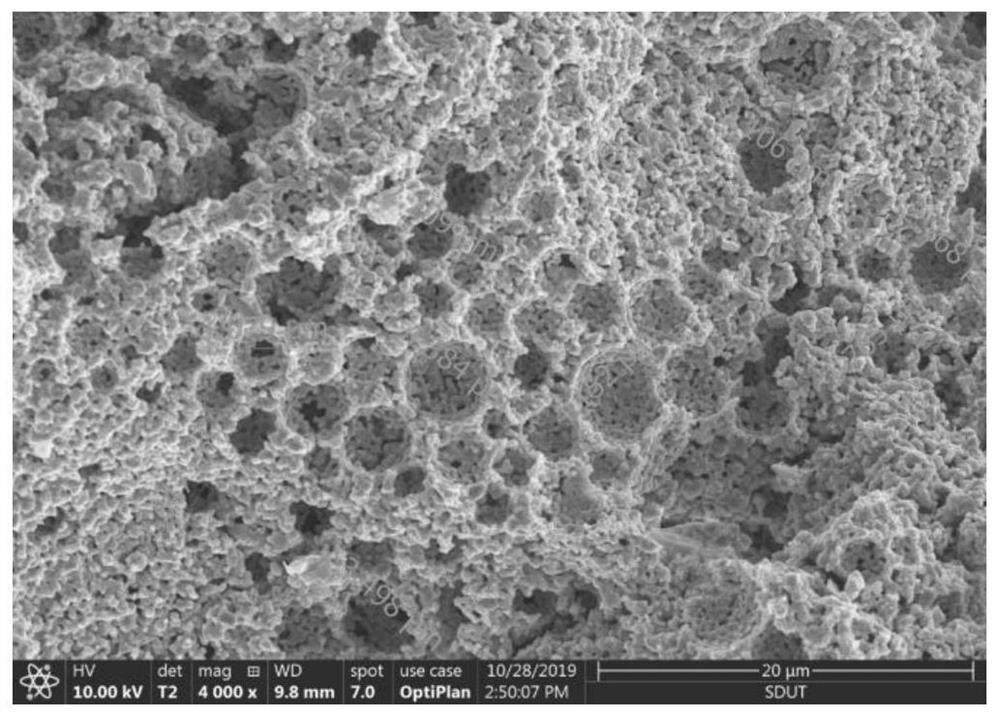

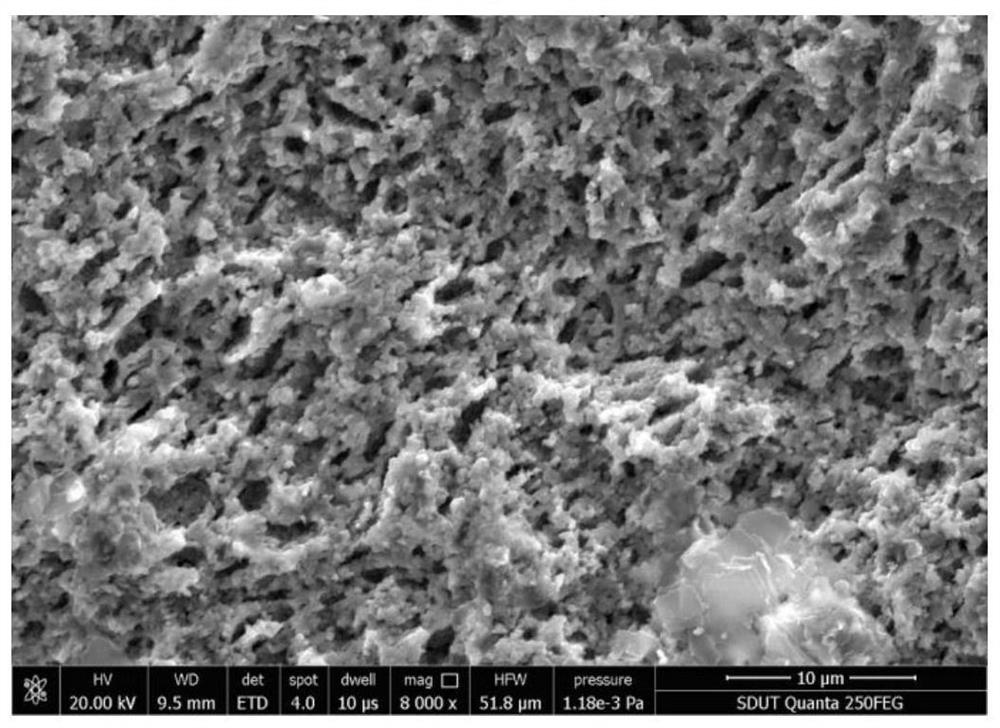

A fuel cell electrode and solid oxide technology, applied in the field of solid oxide fuel cell electrode material and preparation, solid oxide fuel cell three-dimensional network structure electrode and preparation field, can solve the problem of uneven dispersion, reduced porosity, catalytic It can solve the problems of low activity and other problems, and achieve the effect of solving the reduction of electron/ionic conductivity, the reduction of open porosity, and the improvement of catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

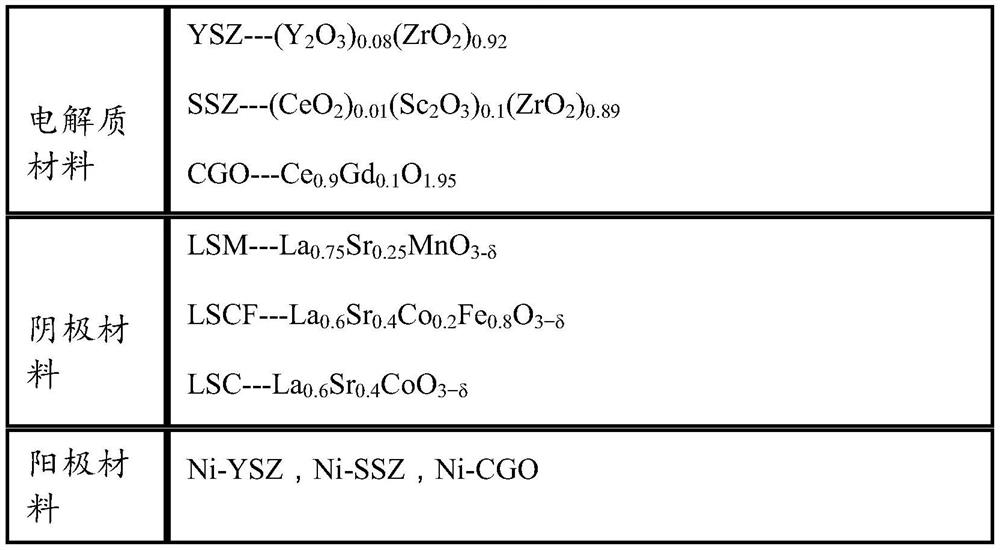

[0041] Electrode materials include anode materials and cathode materials, wherein,

[0042] The preparation process of the solid oxide fuel cell anode material in this embodiment is as follows:

[0043] S1. Put 40 parts of anode raw materials, 2 parts of pore-forming agent, 1 part of dispersant ethanol and 60 parts of water in a ball milling altar in proportion, and ball mill for 1 hour.

[0044] in,

[0045] The pore-forming agent is macromolecule spherical pore-forming agent polyethylene and carbon powder, wherein polyethylene accounts for 80% of the total pore-forming agent.

[0046] S2. Start the constant temperature heating device, and stir the slurry in S1 in a heatable stirring mill for 0.5 hours.

[0047] Among them, the temperature of the constant temperature heating device can be controlled at any temperature within 0-200°C, and the specific temperature is determined according to the heat distortion temperature of the pore-forming agent.

[0048] S3. Continue to m...

Embodiment 2

[0064] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0065] The preparation process of the solid oxide fuel cell anode material in this embodiment is as follows:

[0066] S1. Put 60 parts of anode raw materials, 10 parts of pore-forming agent, 2 parts of dispersant polypropylene alcohol and 40 parts of water in a ball milling altar in proportion, and ball mill for 3 hours.

[0067] in,

[0068] The pore-forming agent is polyvinyl chloride, a spherical pore-forming agent made of polymer material.

[0069] S2. Start the constant temperature heating device, and stir the slurry in S1 in a heatable stirring mill for 2 hours.

[0070] Among them, the temperature of the constant temperature heating device can be controlled at any temperature within 0-200°C, and the specific temperature is determined according to the heat distortion temperature of...

Embodiment 3

[0087] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0088] The preparation process of the solid oxide fuel cell anode material in this embodiment is as follows:

[0089] S1. Put 50 parts of anode raw materials, 7 parts of pore-forming agent, 1 part of dispersant polyacrylamide and 45 parts of water in a ball milling altar in proportion, and ball mill for 2 hours.

[0090] in,

[0091] The pore-forming agent is a spherical pore-forming agent of polymer material polystyrene and starch, wherein polystyrene accounts for 90% of the total amount of the pore-forming agent.

[0092] S2. Start the constant temperature heating device, and stir the slurry in S1 in a heatable stirring mill for 1 hour.

[0093] Among them, the temperature of the constant temperature heating device can be controlled at any temperature within 0-200°C, and the specific t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com