Solvent-free hydrothermal preparation method of carbon material

A technology of carbon materials and hydrothermal method, which is applied in the field of preparation of solvent-free hydrothermal carbon materials, can solve the problems of complicated and time-consuming experimental operations, and achieve the effects of reducing experimental risks, good specific surface area, and saving centrifugal suction and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

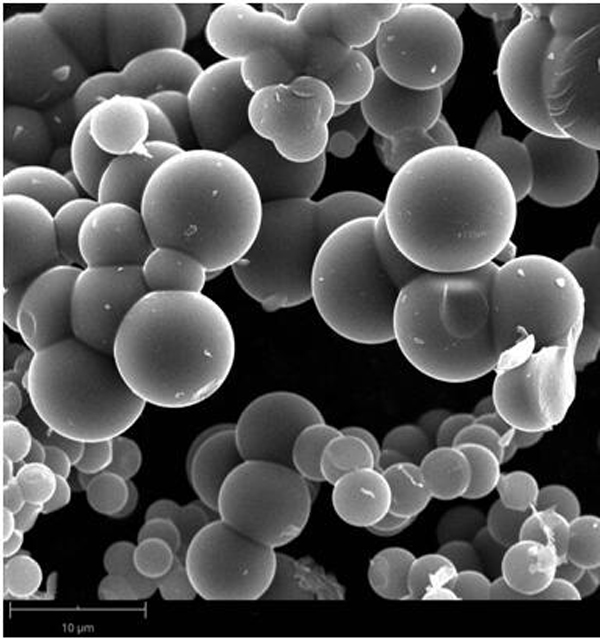

Image

Examples

Embodiment 1

[0026] (1) Take 1g of tannin, 1g of vanillin, and 2g of nano-calcium carbonate and mix them in a mortar. After fully grinding and mixing, add 4-5 drops of 0.5m dilute sulfuric acid to continue grinding, and grind the sample until the surface is wet.

[0027] (2) Transfer the ground sample in step (1) into a 50ml hydrothermal kettle, place it in a vacuum drying oven, and react at 180°C for 12 hours.

[0028] (3) Take out the carbon material precursor in step (2), transfer it into a quartz boat, place it in a tube furnace, and carbonize it in an atmosphere with a nitrogen flow rate of 100 ml / min. The heating rate is 2 °C / min, and the temperature is raised to 900 °C. , After 1.5 hours of heat preservation, cooling treatment.

[0029] (4) The sample obtained in step (3) was ground and pulverized, magnetically stirred with 0.5 m dilute hydrochloric acid for 6 hours, subjected to ultrasonic treatment for 2 hours and then filtered with suction, and the sample was dried in a blast dry...

Embodiment 2

[0032] (1) Take 1g of tannin, 1g of vanillin, and 3g of nano-calcium carbonate and mix them in a mortar. After fully grinding and mixing, add 4-5 drops of 0.5m dilute sulfuric acid to continue grinding, and grind the sample until the surface is wet.

[0033] (2) Transfer the ground sample in step (1) into a 50ml hydrothermal kettle, place it in a vacuum drying oven, and react at 180°C for 11 hours.

[0034] (3) Take out the carbon material precursor in step (2), transfer it into a quartz boat, place it in a tube furnace, and carbonize it in an atmosphere with a nitrogen flow rate of 100 ml / min. The heating rate is 2 °C / min, and the temperature is raised to 900 °C. , After 1.5 hours of heat preservation, cooling treatment.

[0035] (4) The sample obtained in step (3) was ground and pulverized, magnetically stirred with 0.5 m dilute hydrochloric acid for 6 hours, subjected to ultrasonic treatment for 2 hours and then filtered with suction, and the sample was dried in a blast dry...

Embodiment 3

[0038] (1) Take 1g of tannin, 1g of vanillin, and 4g of nano-calcium carbonate and mix them in a mortar. After fully grinding and mixing, add 4-5 drops of 0.5m dilute sulfuric acid to continue grinding, and grind the sample until the surface is wet.

[0039] (2) Transfer the ground sample in step (1) into a 50ml hydrothermal kettle, place it in a vacuum drying oven, and react at 180°C for 10 hours.

[0040] (3) Take out the carbon material precursor in step (2), transfer it into a quartz boat, place it in a tube furnace, and carbonize it in an atmosphere with a nitrogen flow rate of 100 ml / min. The heating rate is 2 °C / min, and the temperature is raised to 900 °C. , After 1.5 hours of heat preservation, cooling treatment.

[0041] (4) The sample obtained in step (3) was ground and pulverized, magnetically stirred with 0.5 m dilute hydrochloric acid for 6 hours, subjected to ultrasonic treatment for 2 hours and then filtered with suction, and the sample was dried in a blast dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com