A plant fiber starch biomass composite material with open cell structure and its preparation method and application

A technology of plant fiber starch and composite materials, which is applied in the field of green production and preparation, can solve the problems of insufficient compressive strength, uneven and fine cells, and long degradation cycle, etc., to improve the overall use effect, improve various properties, and simple adding sequence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

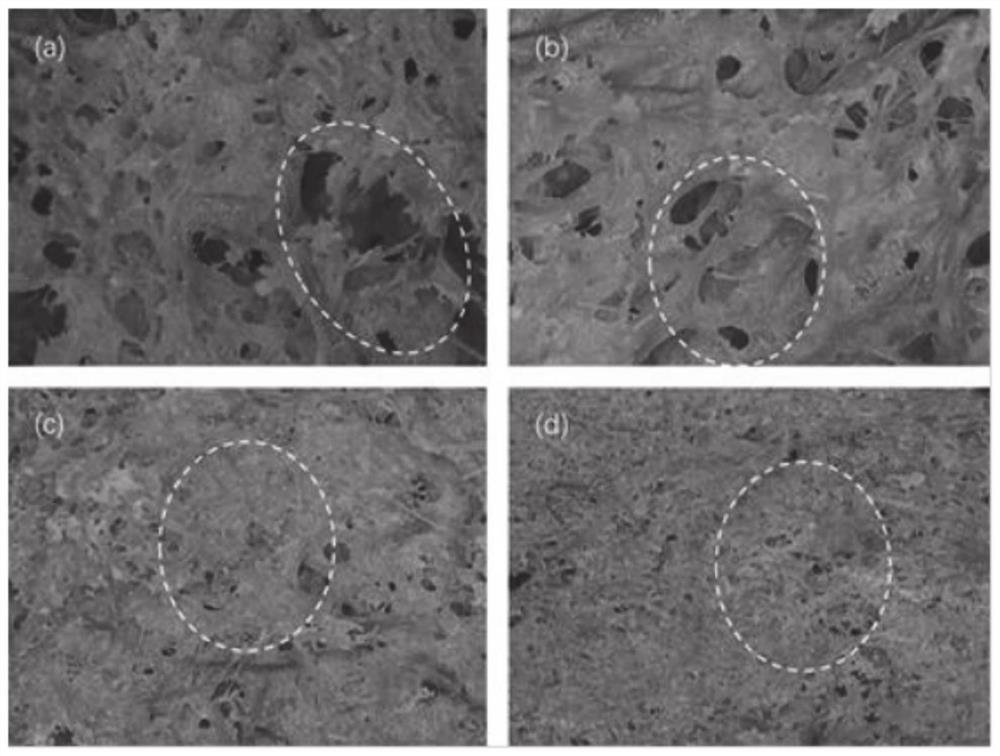

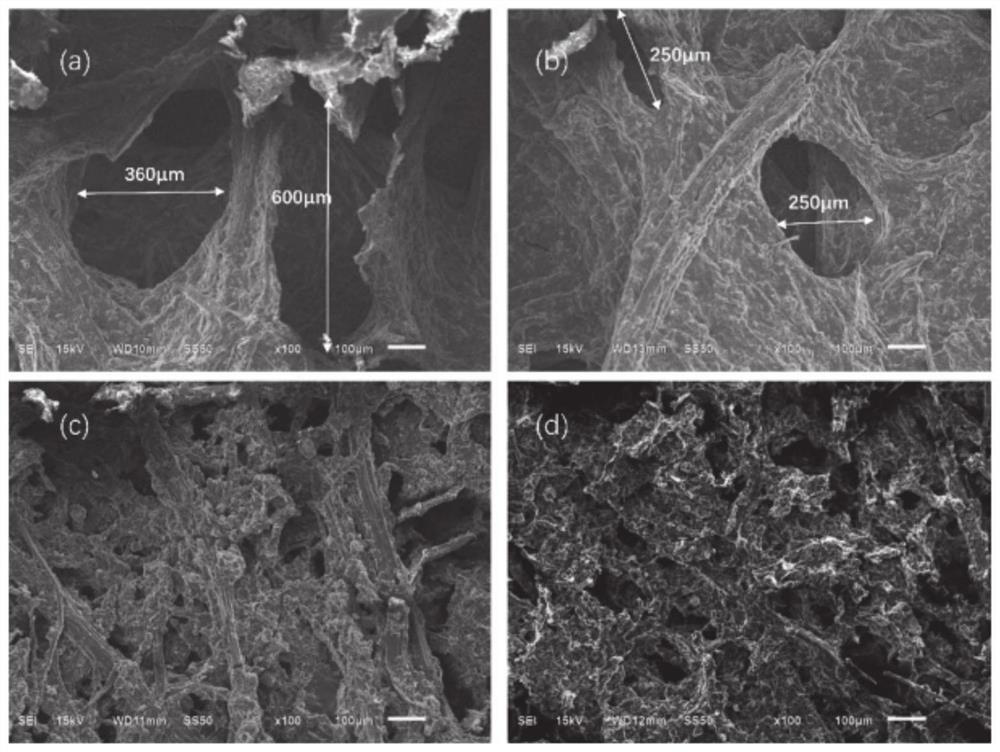

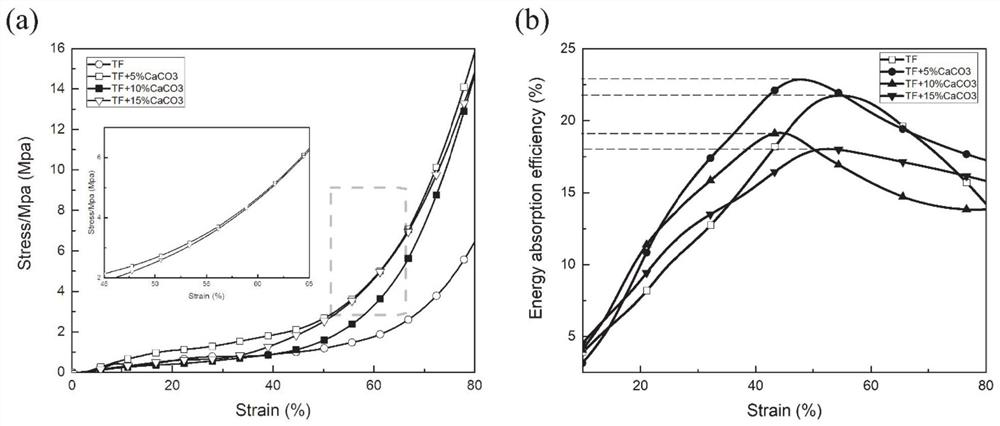

Image

Examples

preparation example Construction

[0040] A kind of preparation method of the plant fiber / lignin fiber / starch biomass composite material of open cell structure, comprises the following steps:

[0041] (1) The plant fibers are mechanically pulverized to obtain 2-5mm fibers, then soaked with hydrogen peroxide for 20-30 minutes, washed with water, and dried to obtain modified plant fibers.

[0042] (2) Take starch and calcium carbonate by weight, put starch, calcium carbonate and hydrogen peroxide into water for gelatinization, the gelatinization temperature is 80-90°C, and the gelatinization time is 20-30 minutes. With even stirring.

[0043] (3) Add foaming agent to the slurry prepared in step (2) and stir evenly for 5 minutes, then add modified sisal fiber, and stir the filler evenly for 35 minutes to obtain the final slurry.

[0044] (4) Put the mixed slurry in step (4) into the mold, set the temperature of the upper mold at 190-210°C, the stability of the lower mold at 190-210°C, and keep the pressure at 6-8...

Embodiment 1

[0049] (1) The sisal fiber was mechanically pulverized to obtain a 5mm fiber, then soaked with 6 parts of hydrogen peroxide for 25 minutes, washed with water until PH = 7, and dried to obtain the modified sisal fiber.

[0050] (2) Take 50 parts of cornstarch and 5 parts, 10 parts, 15 parts of calcium carbonate by weight, starch is put into water with calcium carbonate of different weight parts and 5 parts of hydrogen peroxide respectively and carry out gelatinization treatment, gelatinization temperature The temperature is 85°C, the gelatinization time is 30 minutes, and this process has been accompanied by uniform stirring.

[0051] (3) In the gelatinized starch prepared in step (2), first add 7 parts of azodicarbonamide and stir for 5 minutes, then add 50 parts of modified sisal fibers, and 70 parts of talc powder for 35 minutes, and obtain a uniform Quality mixed slurry.

[0052] (4) Put the mixed slurry in step (4) into the mold, set the temperature of the upper mold to 2...

Embodiment 2

[0064] (1) The rice straw fiber was mechanically pulverized to obtain a fiber of 2 mm, then soaked with 3 parts of urea for 30 minutes, washed with water until PH = 7, and dried to obtain the modified rice straw fiber.

[0065] (2) Take 75 parts of wheat starch and 12 parts of calcium carbonate by weight, put starch, calcium carbonate and 6 parts of sodium hypochlorite into water for gelatinization treatment, the gelatinization temperature is 80°C, and the gelatinization time is 30 minutes. Keep stirring evenly.

[0066] (3) In the gelatinized starch prepared in step (2), first add 5 parts of azodicarbonamide and stir for 8 minutes, then add 30 parts of modified rice straw fibers, and 50 parts of bentonite and stir for 40 minutes to obtain homogeneous Mix slurry.

[0067] (4) Put the mixed slurry in step (4) into the mold, set the temperature of the upper mold to 210°C, the stability of the lower mold to 205°C, and keep the pressure at 6MPa after mold closing to avoid air pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com