Emulsifying viscosity-reducing oil-displacing agent, preparation method and thick oil viscosity-reducing oil-displacing fracturing method

A technology for emulsification of viscosity-reducing and viscous oil-displacing agents, which is applied in chemical instruments and methods, earthwork drilling, and fluid production, etc., can solve the problems of limited contact area between emulsified and viscosity-reducing oil-displacing agents and crude oil, and achieve effective implementation of heavy oil. Use, increase the degree of use, and stabilize the effect for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

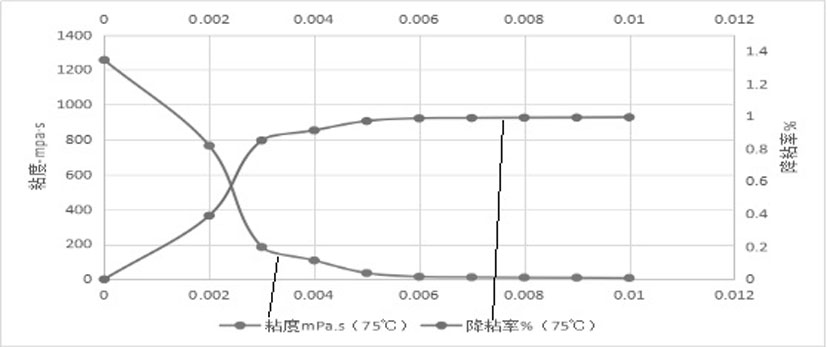

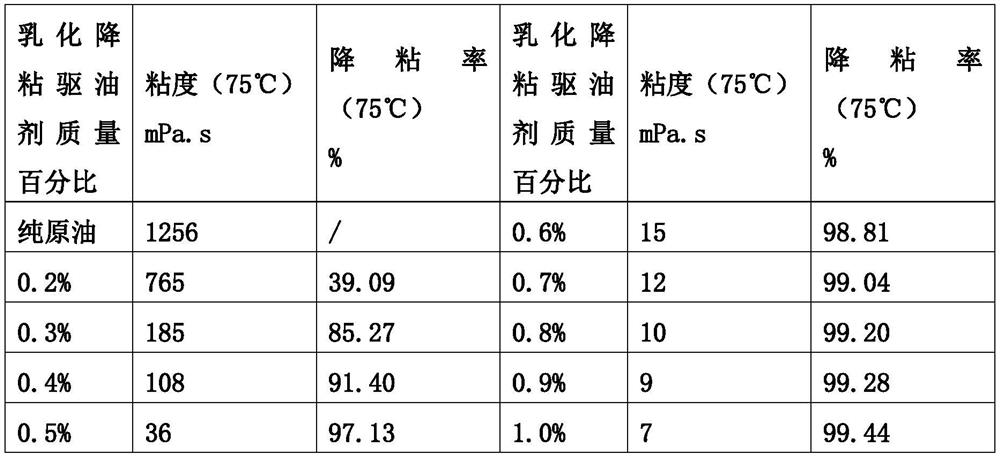

[0023] Embodiment 1: The emulsified viscosity-reducing oil displacement agent, the components include 0 to 20% of heavy alkylphenol polyoxyethylene phosphate, 13% to 26% of polyalkylene polyoxyethylene benzene sulfonate, B Sodium Oxylated Alkyl Sulfate 8% to 22%, Octylphenol Ethoxylate 6% to 12%, Fatty Alcohol Dimethyl Betaine 4% to 6%, Fatty Alcohol Ethoxylate 0 to 12%, 18% to 22% of organic solvent, 0.5% of solubilizer and the balance of water.

[0024] The emulsified viscosity-reducing oil displacement agent is obtained by the following method: mix the required amount of organic solvent and water uniformly to obtain an organic solvent mixture, raise the temperature to 45 to 55°C, and then add the required amount of heavy alkanes to the organic solvent mixture Alkylphenol polyoxyethylene phosphate and polyalkylphenol polyoxyethylene benzene sulfonate, fully stirred and dissolved, and the system was clarified, then added the required amount of ethoxylated alkyl sodium sulfate...

Embodiment 2

[0030] Embodiment 2: As the optimization of the foregoing embodiment, the emulsified viscosity-reducing oil displacement agent comprises polyalkylene polyoxyethylene benzene sulfonate 24% to 26%, ethoxylated sodium alkyl sulfate 8% to 12%, fatty alcohol Polyoxyethylene ether 8% to 12%, octylphenol polyoxyethylene ether 8% to 12%, fatty alcohol dimethyl betaine 4% to 6%, organic solvent 18% to 22%, solubilizer 0.5%, the rest The amount is water.

[0031] For heavy oil with a crude oil viscosity of 50mPa·s to 20000mPa·s at 50°C, at low speed shear (can be less than 170s -1 ) conditions, the components described in Example 2 have a strong emulsification and viscosity-reducing ability, and have a strong wetting inversion, oil washing and oil displacement ability, and the emulsion has a long stable time.

Embodiment 3

[0032] Embodiment 3: As the optimization of the foregoing embodiment, the emulsified viscosity-reducing oil displacement agent comprises 15% to 20% of heavy alkylphenol polyoxyethylene phosphate, 13% to 15% of polyalkylene polyoxyethylene benzene sulfonate, B Oxylated alkyl sodium sulfate 18% to 22%, octylphenol polyoxyethylene ether 6% to 10%, fatty alcohol dimethyl betaine 4% to 6%, organic solvent 18% to 20%, solubilizer 0.5% %, the balance is water.

[0033] For heavy oil with a crude oil viscosity of 20,001mPa·s to 50,000mPa·s at 50°C, at low speed shear (can be lower than 170s -1 ) conditions, the components described in Example 3 have a strong emulsification and viscosity-reducing ability, and have a strong wetting inversion, oil washing and oil displacement ability, and the emulsion has a long stable time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com