Ultrasonic-assisted oyster freezing method

An ultrasonic and oyster technology, applied in the direction of preservation of meat/fish by freezing/cooling, preservation of meat/fish by radiation/electrical treatment, application, etc., can solve the problem of reducing the water loss rate of shrimp, not suitable for mass freezing, and unfavorable economic development, etc. problem, to achieve the effect of shortening the freezing time, maintaining quality and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

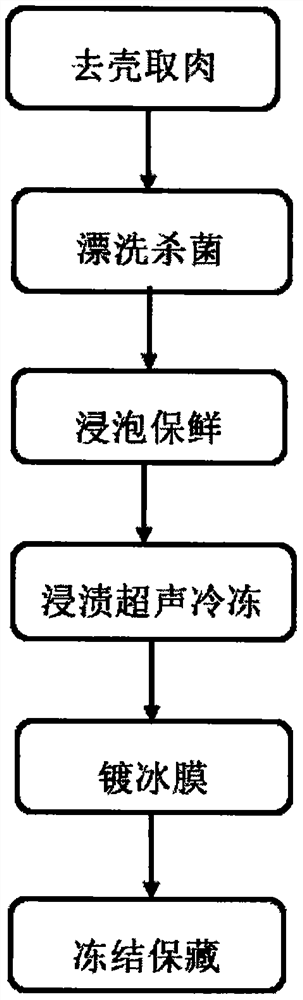

[0028] A method of ultrasonically assisted soaking frozen oysters comprises the following steps:

[0029] a. Remove the shell and take the meat: wash the impurities on the surface of the oyster shell with running water, use pliers and other tools to open the shell and take the meat.

[0030] b. Rinse and sterilize: use 0.9mg / L ozone water for 8 minutes for disinfection and sterilization, and control the temperature of the ozone water at about 10°C.

[0031] c. Soaking to keep fresh: put the rinsed and sterilized oysters into 1.5% sodium chloride, 0.2% citric acid soaking solution and soak for 40 minutes, the soaking temperature is about 4°C, and the ratio of solid to liquid is 1:8.

[0032] d. Ultrasonic assisted immersion freezing: put the soaked oysters into the immersion solution at -20°C and freeze them. The immersion solution is composed of: 30% calcium chloride, 4% trehalose, 0.3% tea polyphenols, and 1% citric acid , 4% phytic acid, 2% xylitol, the ratio of solid to li...

Embodiment 2

[0036] A method of ultrasonically assisted soaking frozen oysters comprises the following steps:

[0037] a. Remove the shell and take the meat: wash the impurities on the surface of the oyster shell with running water, use pliers and other tools to open the shell and take the meat.

[0038] b. Rinse and sterilize: use 1.0mg / L ozone water for 7 minutes to disinfect and sterilize, and control the temperature of the ozone water at about 10°C.

[0039] c. Soaking treatment: After rinsing and sterilization, the oysters are soaked in 1.5% sodium chloride and 0.2% citric acid soaking solution for 40 minutes, the soaking temperature is about 4°C, and the ratio of solid to liquid is 1:8.

[0040] d. Ultrasonic assisted immersion freezing: put the soaked oysters into the immersion solution at -20°C for immersion freezing. The immersion solution is composed of: 30% calcium chloride, 6% trehalose, 0.4% tea polyphenols, 1% citric acid , 5% phytic acid, 2% xylitol, the ratio of solid to l...

Embodiment 3

[0044] A method of ultrasonically assisted soaking frozen oysters comprises the following steps:

[0045] a. Remove the shell and take the meat: wash the impurities on the surface of the oyster shell with running water, use pliers and other tools to open the shell and take the meat.

[0046] b. Rinse and sterilize: use 1.2mg / L ozone water for 5 minutes to disinfect and sterilize, and control the temperature of the ozone water at about 10°C.

[0047] c. Soaking treatment: After rinsing and sterilization, the oysters are soaked in the soaking solution of 1.5% sodium chloride and 0.2% citric acid for 40 minutes, the soaking temperature is about 4°C, and the ratio of solid to liquid is 1:8.

[0048] d. Ultrasonic-assisted immersion freezing: put the soaked oysters into the immersion solution at -20°C for immersion freezing. The immersion solution is composed of: 30% calcium chloride, 8% trehalose, 0.5% tea polyphenols, and 1% citric acid , 6% phytic acid, 2% xylitol, the ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com