Treatment system and treatment method for activated carbon desulfurization and denitrification acid-making wastewater

A desulfurization, denitrification, and treatment system technology is applied in the field of activated carbon desulfurization and denitration acid-making wastewater treatment system, which can solve the problems of poor operation of the acid-making wastewater treatment system, complex wastewater pollution factors, and difficulty in recycling. Effects of sulfur trioxide and heavy metal mercury, reduction of abnormally high temperature phenomenon, and reduction of operating burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

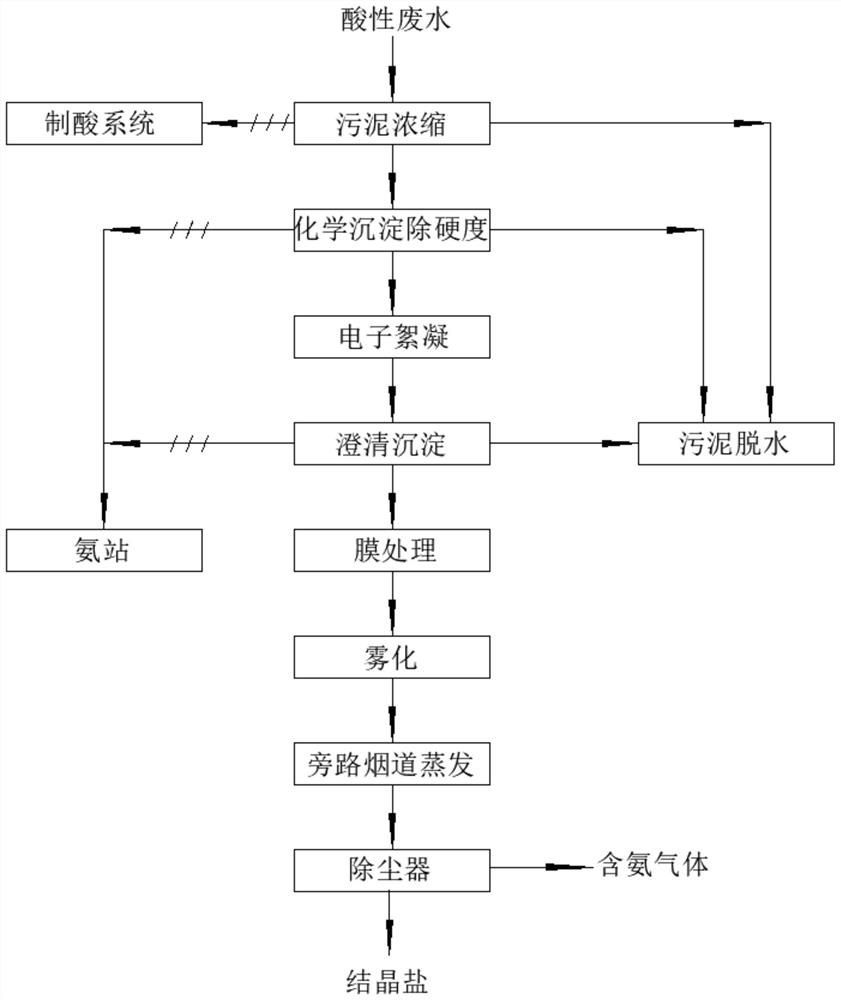

[0037] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. The invention provides a treatment method and system for activated carbon desulfurization and denitrification acid-making wastewater, which can effectively treat and recycle the activated coke flue gas-purified acid-making wastewater, and realize zero discharge of the acid-making wastewater.

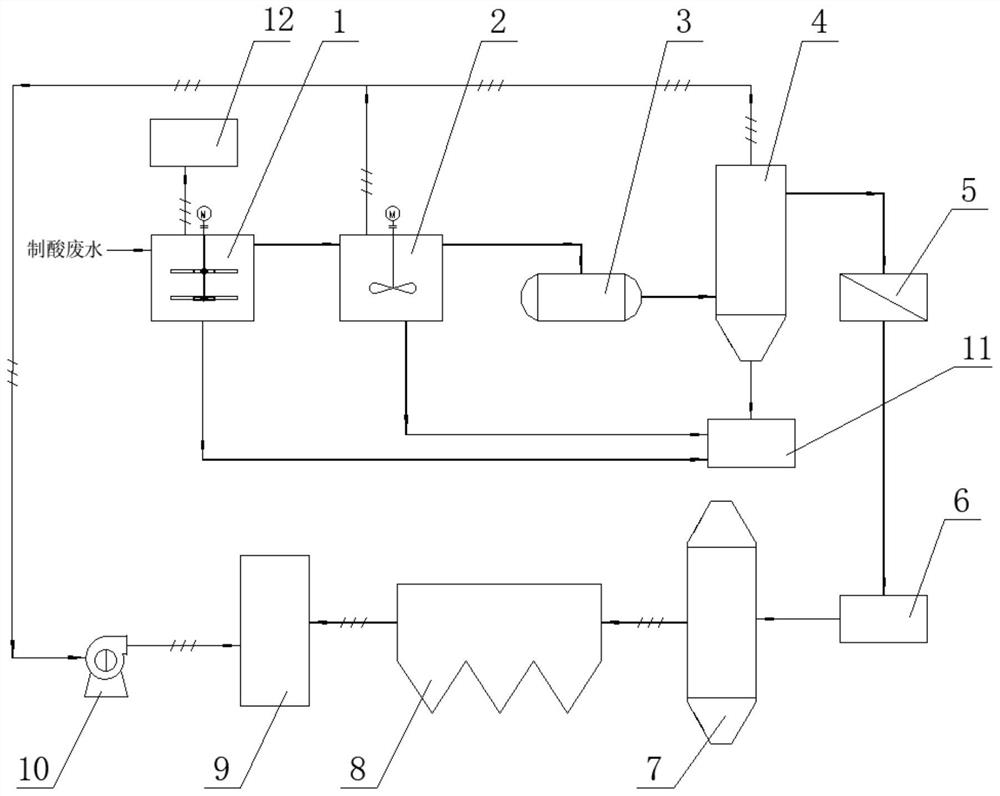

[0038] figure 1 It is a structural schematic diagram of a treatment system for activated carbon desulfurization and denitrification acid production wastewater related to an embodiment of the present invention.

[0039] Please refer to figure 1 , In this embodiment, a treatment system for acid-making wastewater from activated coke flue gas purification is given, which is used to treat the acid-making wastewater f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com