Mercapto-terminated polyurethane modified epoxy mortar and preparation method thereof

A polyurethane modification and mercapto-terminated technology, which is applied in the field of building materials, can solve the problems of long curing period, easy foaming, and difficult complete curing, etc., and achieve the effects of fast curing speed, improved toughness, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

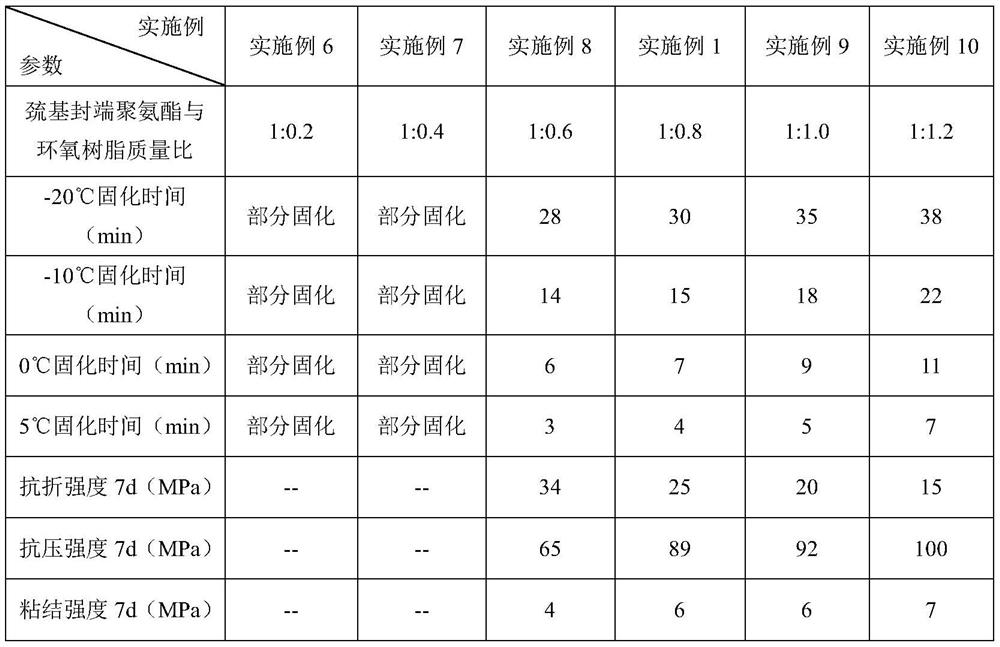

Embodiment 1

[0032] A kind of epoxy mortar modified by mercapto-terminated polyurethane, made of mercapto-terminated polyurethane, epoxy resin, accelerator and quartz sand, the mass ratio of mercapto-terminated polyurethane, epoxy resin, accelerator and quartz sand is 1 :0.8:0.02:7; wherein, the epoxy resin is formed by mixing bisphenol A epoxy resin E44 and diglycidyl ether in a mass ratio of 4:1, and the accelerator is 1,8-diazepine Bicyclo[5,4,0]undec-7-ene, the particle size of the quartz sand is 70-140 mesh.

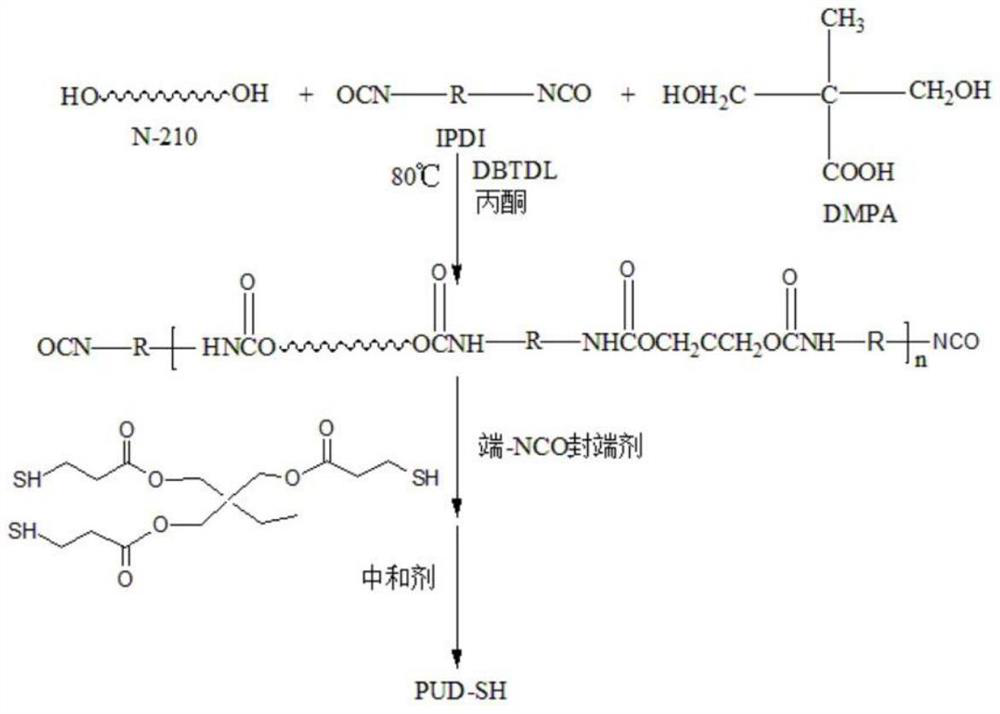

[0033] The preparation method of described mercapto-terminated polyurethane is:

[0034] a. Add isophorone diisocyanate (19.03g), polyether N-210 (21.11g) and dibutyltin dilaurate (0.15g) into the reaction vessel, react at 80°C for 5h; then add dimethylol Propionic acid solution (3.02g) was reacted at 80°C for 5h; wherein, the mass ratio of isophorone diisocyanate to polyether N-210, dibutyltin dilaurate, and dimethylol propionic acid solution was 1:1.1 :0.008:0.16, dimethylol...

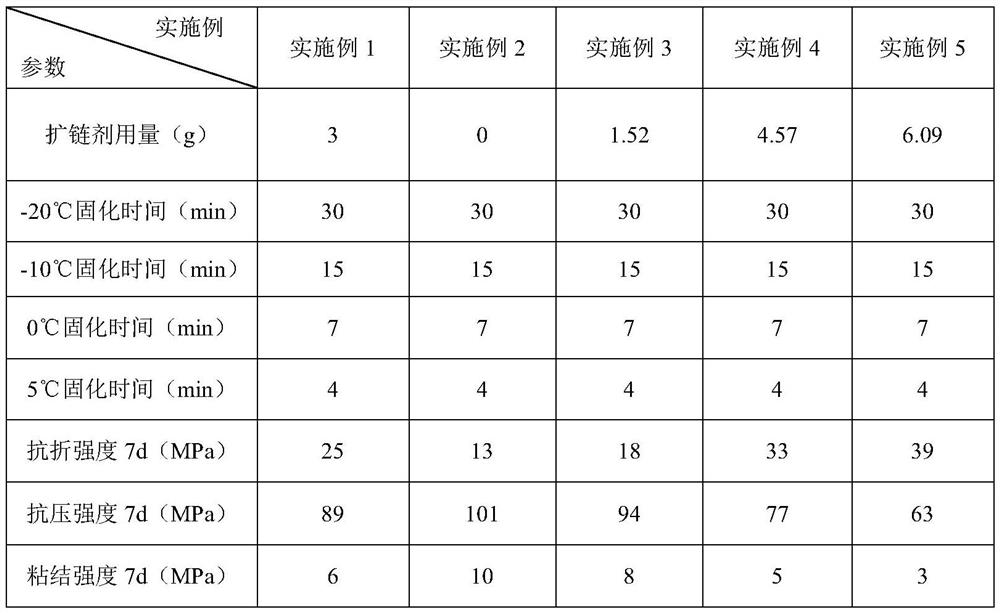

Embodiment 2

[0038] The content of embodiment 2 is basically the same as embodiment 1, and its difference is:

[0039] In the preparation method of the mercapto-terminated polyurethane: the mass ratio of isophorone diisocyanate to polyether N-210, dibutyltin dilaurate, and dimethylol propionic acid solution is 1:1.1:0.008:0, namely The amount of chain extender—dimethylol propionic acid solution is 0 g.

Embodiment 3

[0041] The content of embodiment 3 is basically the same as embodiment 1, and its difference is:

[0042]In the preparation method of the mercapto-terminated polyurethane: the mass ratio of isophorone diisocyanate to polyether N-210, dibutyltin dilaurate, and dimethylol propionic acid solution is 1:1.1:0.008:0.08, namely The amount of chain extender—dimethylolpropionic acid solution is 1.52g, and the dimethylolpropionic acid solution is prepared with N-methylpyrrolidone as a solvent, and its concentration is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com