Composite microsphere with core-shell structure and preparation method thereof

A technology of composite microspheres and core-shell structure, which is applied in the field of composite microspheres with core-shell structure and its preparation, can solve the problems of poor compatibility of matrix materials, little deviation of refractive index, influence of flame retardancy of products, etc. Achieve the effect of diverse performance, adjustable performance performance, and improved microsphere performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] In the second aspect of the present invention, a method for preparing composite microspheres with a core-shell structure and a radial fibrous mesoporous shell structure is provided, comprising the steps of:

[0075]i) adding an organic silicon source or a mixed silicon source of an organic silicon source and an inorganic silicon source to an alkaline aqueous solution for the first polymerization reaction to obtain a first reaction mixture containing core microspheres, and filtering or centrifuging the reaction mixture Separation to obtain the core microspheres;

[0076] ii) Disperse the above-mentioned core microspheres in water, stir to form a uniform dispersion; add the above-mentioned dispersion to an aqueous solution containing an emulsifier and a catalyst, ultrasonically disperse, and then add an inorganic silicon source or an inorganic silicon source and an organic The mixed silicon source of the silicon source is subjected to a second polymerization reaction, and...

Embodiment 1

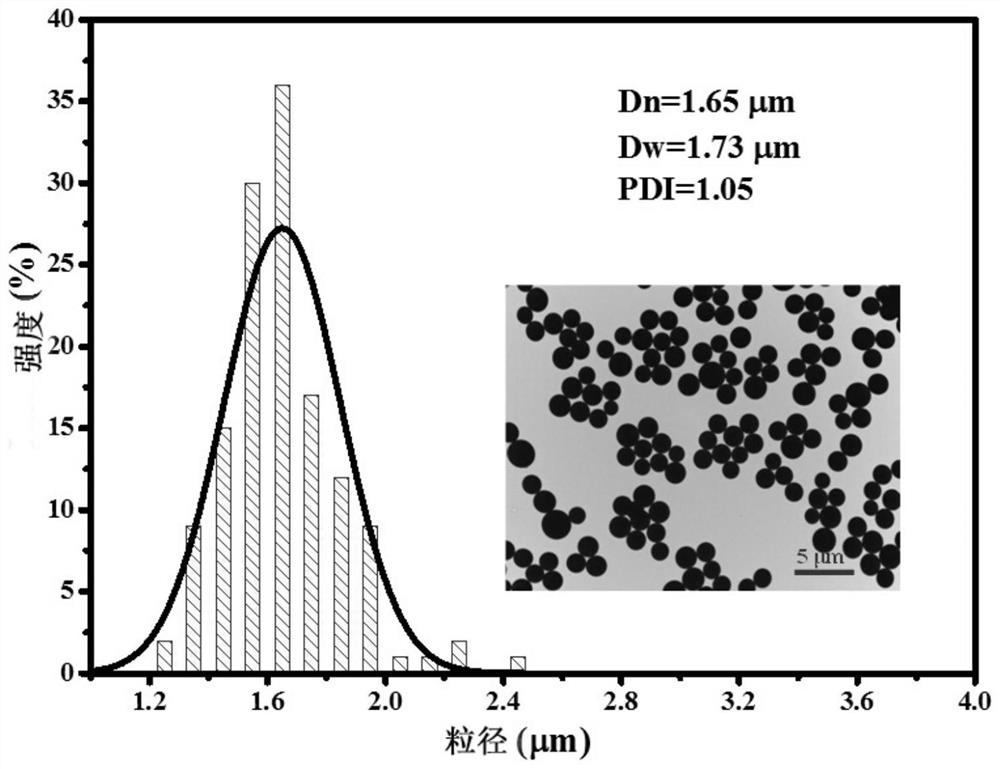

[0092] Take 100g of water, heat it to 65°C, add 5g of methyltrimethoxysilane, add 0.5mol / L NaOH solution under stirring, adjust the pH value to 9.5, react for 1h, neutralize with 0.5mol / L sulfuric acid solution, filter , to obtain microspheres (core microspheres) with an average particle size of 1.6 μm, such as figure 1 shown.

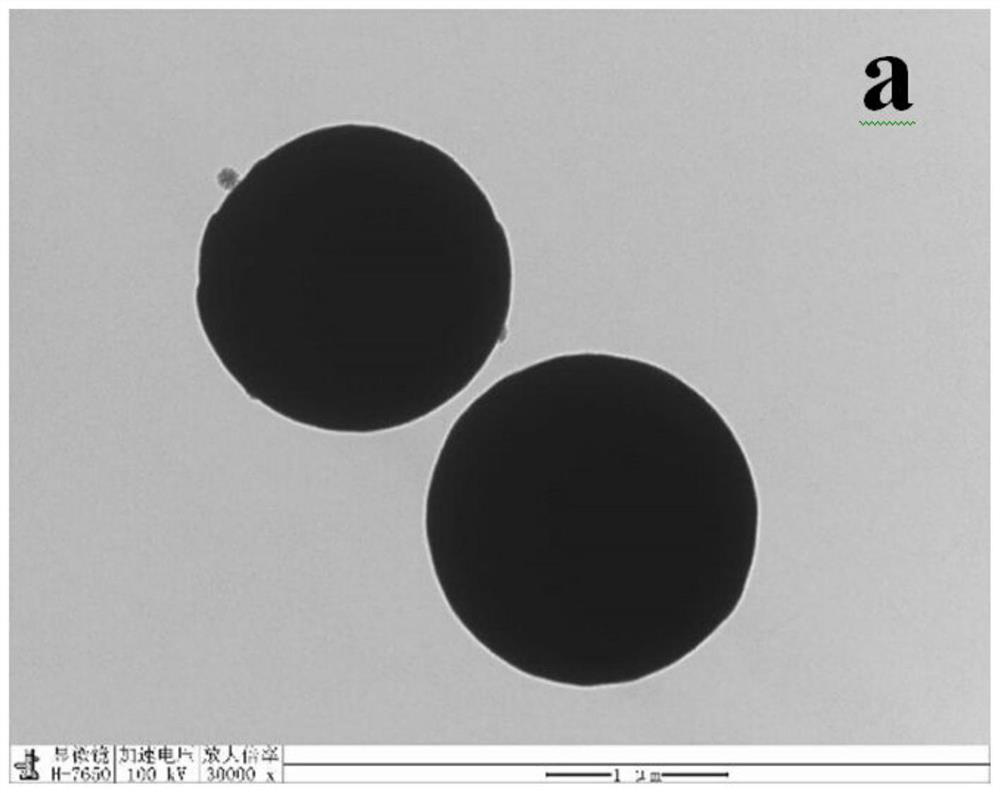

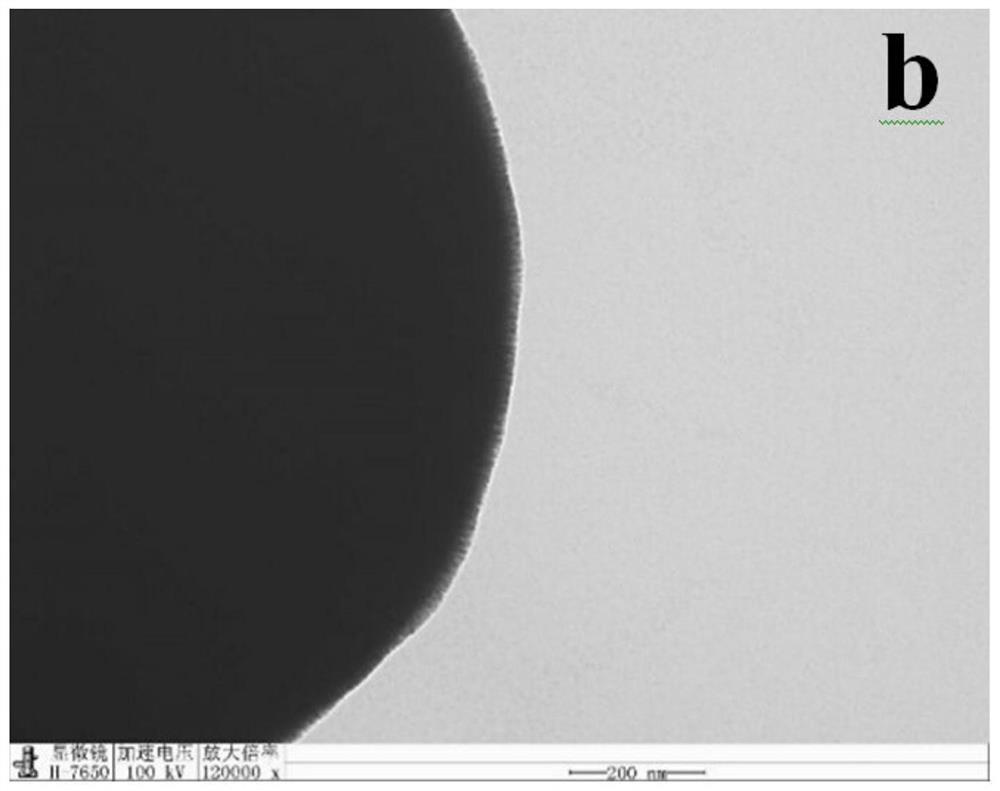

[0093] Disperse the above-mentioned core microspheres in water to prepare a dispersion liquid with a mass fraction of 20%. Measure 25 g of this dispersion liquid and add it to a 250 mL three-neck flask containing a mixture of 2.4 g cetyltrimethylammonium p-toluenesulfonate, 0.43 g triethanolamine and 100 g distilled water, and continue ultrasonication for 5 min. The three-neck flask was placed in an oil bath, fixed, and 5 g of tetraethyl orthosilicate was added under mechanical stirring (250 rpm), and the temperature of the system was raised to 70° C. for 16 hours. After the system was cooled to room temperature, 50 g of ethanol was added to the reac...

Embodiment 2

[0095] Take 100g of water, heat it to 65°C, add 1.8g of phenyltrimethoxysilane, 0.35g of methyltrimethoxysilane and 0.5g of methylphenyldimethoxysilane mixture, add 0.5mol / L NaOH solution under stirring , adjust the pH value to 9.2, react for 1 h, neutralize with 0.5 mol / L sulfuric acid solution, and centrifuge at high speed to obtain microspheres (core microspheres) with an average particle size of 1.5 μm. Disperse the core microspheres in water to form a 20% dispersion.

[0096] Take 100 g of distilled water, add 3.5 g of cetyltrimethylammonium bromide, stir, and add 18 g of the above-mentioned core microsphere dispersion. Add 0.6 g of triethanolamine, then add 3.5 g of tetraethyl orthosilicate, raise the temperature to 70° C., and react for 5 hours. Composite microspheres with core-shell structure ( Figure 6 and its partially enlarged view - Figure 7 ), the average particle size of the core microsphere is 1.5 microns, and the thickness of the fibrous mesoporous shell i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com