SOI lateral insulated gate bipolar transistor

A technology of bipolar transistors and insulated gates, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems that limit the application of ordinary anode short-circuit structure IGBT devices, etc., to reduce the current conduction path, increase the saturation current, and forward voltage drop Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

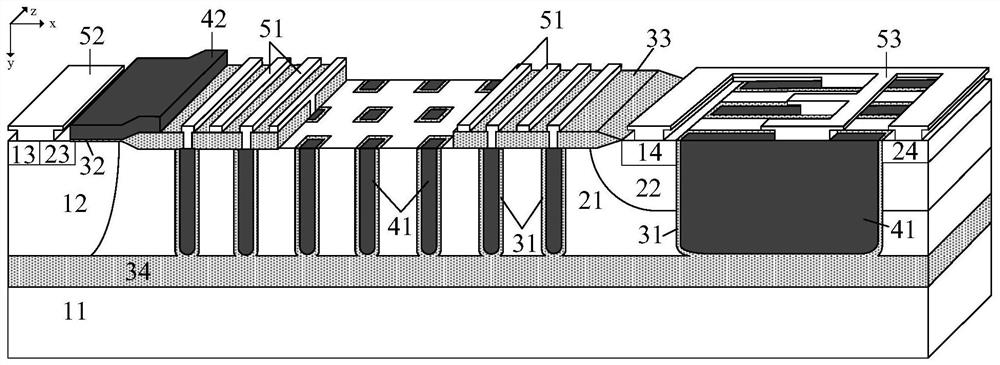

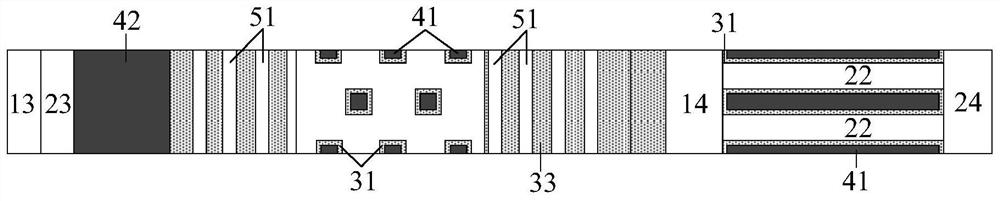

[0032] A lateral insulated gate bipolar transistor device described in Embodiment 1, such as figure 1 and figure 2 shown, including:

[0033] First conductivity type semiconductor substrate 11, first conductivity type well region 12, first conductivity type heavily doped emitter region 13, first conductivity type heavily doped collector region 14, second conductivity type drift region 21, Two conductive type well region 22 , second conductive type heavily doped emitter region 23 , second conductive type heavily doped collector region 24 , first dielectric oxide layer 31 , second dielectric oxide layer 32 , third dielectric oxide layer 33, buried oxide layer 34, polysilicon electrode 41, control gate polysilicon electrode 42, metal strip 51, emitter contact electrode 52, collector contact electrode 53;

[0034] The buried oxide layer 34 is located above the first conductive type semiconductor substrate 11 , the second conductive type drift region 21 is located above the buri...

Embodiment 2

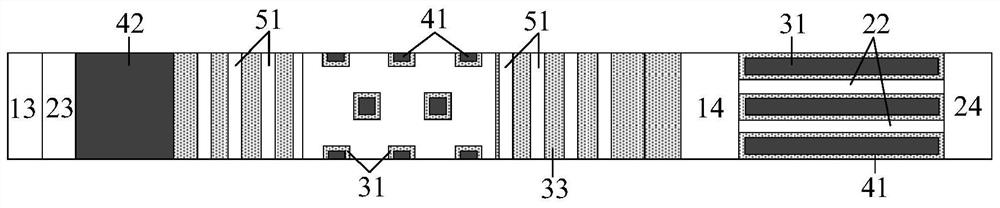

[0046] like image 3 As shown, it is a schematic structural diagram of the SOI lateral insulated gate bipolar transistor of Embodiment 2. The difference between the structure of this embodiment and Embodiment 1 is that the distribution of the vertical field plates in the collector region is different. In this embodiment, the adjacent two The interval between the column longitudinal field plates is reduced, and the length of the field plates is shortened to reach the anode resistance size that can eliminate the Snapback effect. The working principle is basically the same as that of the first embodiment.

Embodiment 3

[0048] like Figure 4 As shown, it is a top view of the SOI lateral insulated gate bipolar transistor structure of Embodiment 3. The difference between the structure of this embodiment and Embodiment 1 is that by reducing the width of the etched deep groove, the oxide layer in the later oxidation process of the groove wall is reduced. Filling the trench completely, the collector region longitudinal field plate becomes a dielectric trench. Adjust the interval of the medium tank to obtain a suitable anode resistance size to eliminate the Snapback effect. The working principle is basically the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com