Flame-retardant polystyrene material and preparation method thereof

A polystyrene and styrene technology, applied in the field of polystyrene modified materials, can solve the problems of increasing the weight of foam materials and affecting the lightweight, and achieve the effect of improving the flame retardant effect and reducing the weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

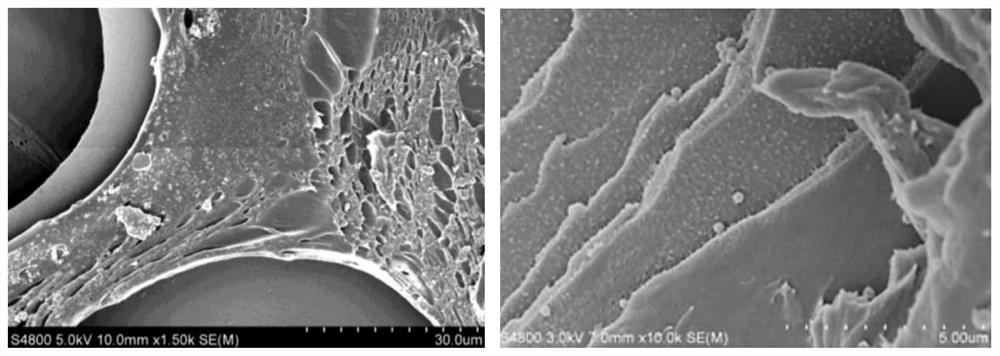

Image

Examples

Embodiment 1

[0033] Embodiment 1: Prepare flame-retardant polystyrene material as follows:

[0034] (1) Preparation of aqueous phase solution: get 100 parts by weight of deionized water and add it to the reactor, measure 5 parts by weight of polyvinyl alcohol aqueous solution with a concentration of 4wt%, 1 part by weight of active calcium phosphate and 0.6 parts by weight of a concentration of 0.2wt% Add the sodium dodecylbenzenesulfonate aqueous solution into the reactor, heat to 50°C to fully dissolve, then add 4 parts by weight of expanded graphite powder to the reactor and mix well; the maximum particle size of the expanded graphite powder is 500nm. Due to the hydrophobicity and electrostatic repulsion of the expanded graphite powder, it will be evenly dispersed after entering the water, and will not agglomerate with each other to form larger particles, which is conducive to the uniform transfer to the oil phase in the next step.

Embodiment 2

[0044] Embodiment 2: Prepare flame-retardant polystyrene material as follows:

[0045] (1) Water phase solution preparation: get 100 parts by weight of deionized water and add in the reactor, measure 5 parts by weight of polyvinyl alcohol aqueous solution, 1 part by weight of active calcium phosphate and 0.6 parts by weight of 0.2 wt% concentration Add the sodium dodecylbenzenesulfonate aqueous solution into the reactor, heat to 50°C to fully dissolve, then add 6 parts by weight of expanded graphite powder to the reactor and mix well; the maximum particle size of the expanded graphite powder is 500 μm.

[0046] (2) Preparation of oil phase solution: styrene: triphenyl phosphate is added to the mixing container at a weight ratio of 10:1, triphenyl phosphate and benzoyl peroxide are added and stirred until completely dissolved in styrene to obtain The mixed solution is the mixed oil phase; the added amount of the benzoyl peroxide is 1.5% of the mixed solution; the added amount o...

Embodiment 3

[0055] Embodiment 3: prepare flame-retardant polystyrene material as follows:

[0056] (1) Water phase solution preparation: get 100 parts by weight of deionized water and add in the reactor, measure 5 parts by weight of polyvinyl alcohol aqueous solution, 1 part by weight of active calcium phosphate and 0.6 parts by weight of 0.2 wt% concentration Add the sodium dodecylbenzenesulfonate aqueous solution into the reaction kettle, heat to 50°C to fully dissolve, then add 5 parts by weight of expanded graphite powder to the reaction kettle and mix well; the maximum particle size of the expanded graphite powder is 250 μm.

[0057] (2) Preparation of oil phase solution: styrene: triphenyl phosphate is added to the mixing container at a weight ratio of 10:1, triphenyl phosphate and benzoyl peroxide are added and stirred until completely dissolved in styrene to obtain The mixed solution is the mixed oil phase; the added amount of the benzoyl peroxide is 1.35% of the mixed solution; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com