Preparation method for cerium base polishing powder used for optical glass and liquid crystal display glass

A liquid crystal display, optical glass technology, applied in chemical instruments and methods, polishing compositions containing abrasives, other chemical processes, etc., can solve the problems of low degree of spheroidization, large hardness range, wide particle size distribution, etc. The effect of good surface finish, long service life and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

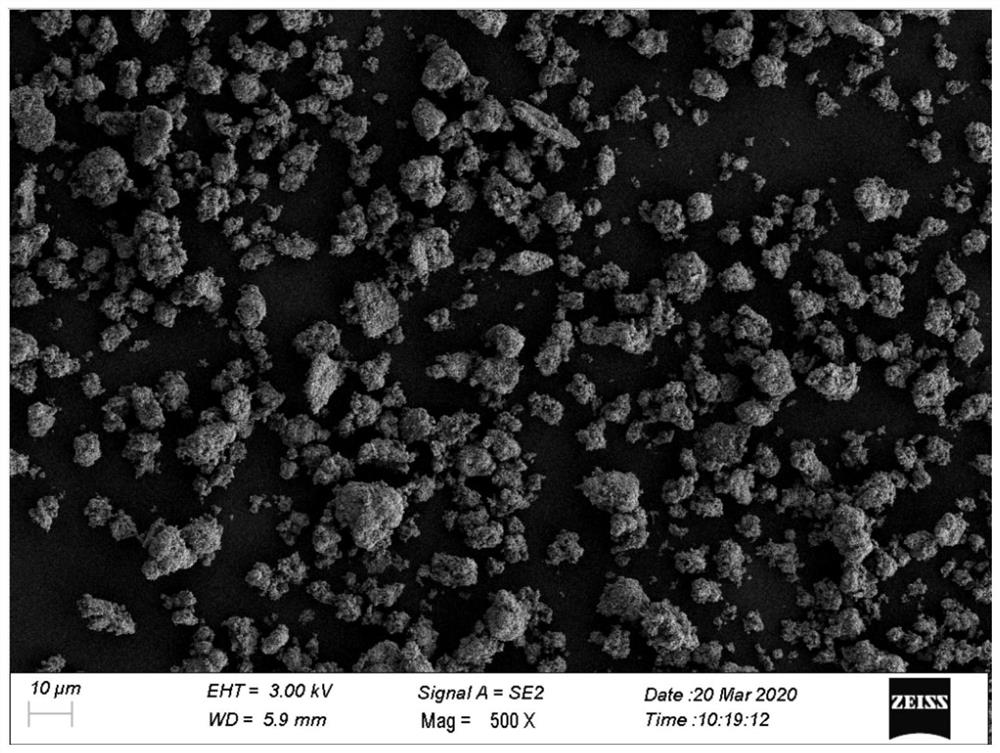

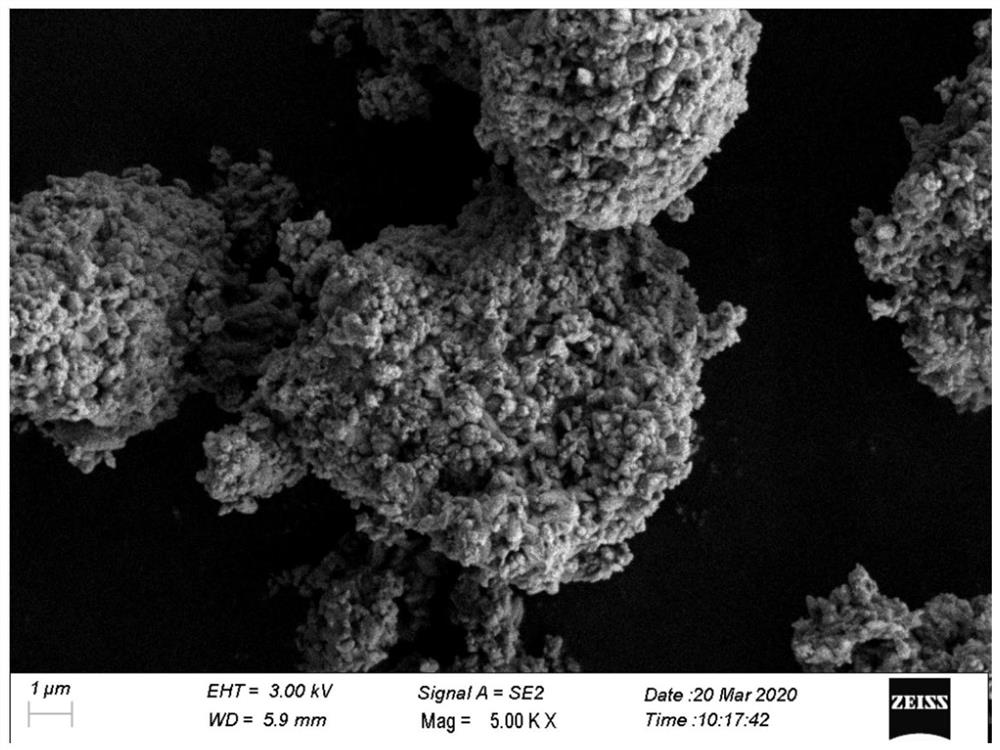

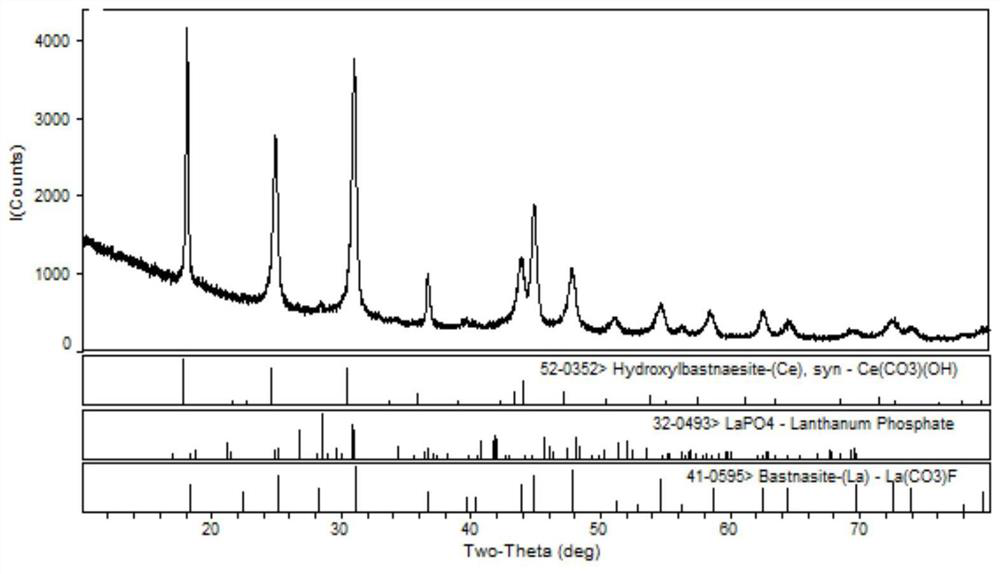

[0044] A preparation method of cerium-based polishing powder for optical glass and liquid crystal display glass, which includes S1. Precursor preparation and S2. Precursor burning, wherein:

[0045] S1. Precursor preparation: Heat the aqueous solution of lanthanum cerium chloride with a concentration of 50g / l to 50°C, and add a composite precipitant solution with a phosphate root concentration of 2g / l under stirring, and the addition rate of the composite precipitant solution is 2000l / h , stop adding until the pH reaches 5.5, keep warm and continue to stir and age for 1h, separate the solid from the liquid, add pure water to the solid to wash until the conductivity of the supernatant reaches below 6000us / cm, then vacuum filter and dry to obtain rare earth polishing powder the precursor of

[0046] S2. Ignition of the precursor: the precursor obtained in the preparation of the S1. precursor was calcined at 700° C. for 5 hours in an air atmosphere to obtain a preliminary cerium-...

Embodiment 2

[0049] A method for preparing a cerium-based polishing powder precursor for optical glass and liquid crystal display glass, comprising S1. Precursor preparation and S2. Polishing powder preparation, wherein:

[0050] S1. Preparation of precursor: Heat the aqueous solution of lanthanum and cerium chloride with a concentration of 100g / l to 70°C, and add a composite precipitant solution with a phosphate root concentration of 3g / l under stirring, and the addition speed of the composite precipitant solution is 1000l / h , stop adding until the pH reaches 7.5, keep warm and continue to stir and age for 2h, separate the solid from the liquid, add pure water to the solid to wash until the conductivity of the supernatant reaches below 6000us / cm, then vacuum filter and dry to obtain rare earth polishing powder the precursor of

[0051] S2. Ignition of the precursor: the precursor obtained in the preparation of the S1. precursor was calcined at 850° C. for 5 hours in an air atmosphere to obt...

Embodiment 3

[0054] A preparation method of cerium-based polishing powder for optical glass and liquid crystal display glass, which includes S1. Precursor preparation and S2. Precursor burning, wherein:

[0055] S1. Precursor preparation: Heat the aqueous solution of lanthanum and cerium chloride with a concentration of 300g / l to 90°C, add a composite precipitant solution with a phosphate root concentration of 6g / l under stirring, and add the composite precipitant solution at a speed of 500l / h , stop adding until the pH reaches 7, keep warm and continue to stir and age for 4h, separate the solid from the liquid, add pure water to the solid to wash until the conductivity of the supernatant reaches below 6000us / cm, then vacuum filter and dry to obtain rare earth polishing powder the precursor of

[0056] S2. Ignition of the precursor: the precursor obtained in the preparation of the S1. precursor was calcined at 1200° C. for 2 hours in an air atmosphere to obtain a preliminary cerium-based p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com