Locking glue array lead frame and application thereof in chip packaging piece

A glue-locking array lead and lead frame technology, which is applied to the glue-locking array lead frame and its application in chip packages, can solve the problem of limited number of openings, unsatisfactory contact effect between bonding wire and copper material, and meaning of use There are no major problems, and the effect of improving reliability is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

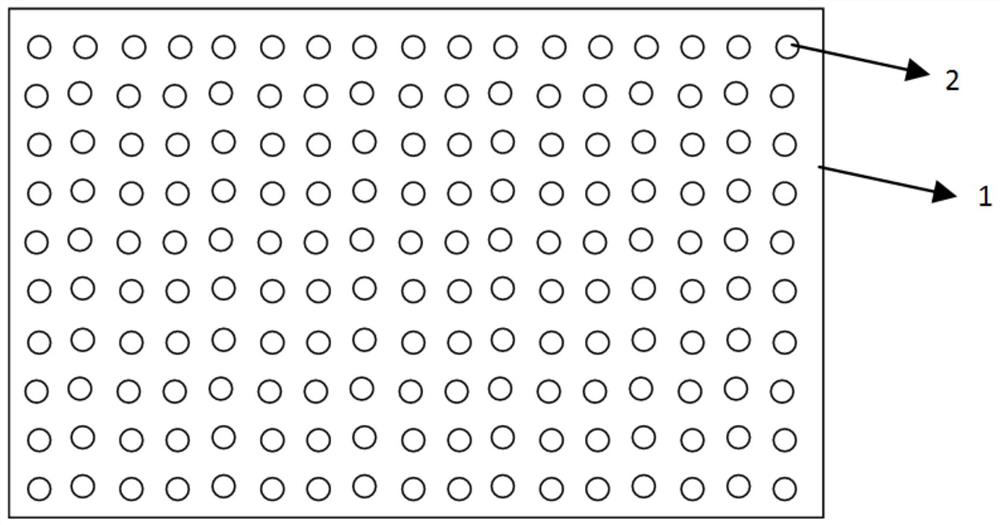

[0062] A kind of adhesive lock array lead frame of the present invention, as figure 1 As shown, the lead frame substrate 1 is rectangular, and its surface is provided with a glue-locking structure. The glue-locking structure is a circular glue-locking hole 2 evenly distributed on the lead-frame substrate. The diameter of the circular glue-locking hole 2 is 300um, the distance between the edges of two adjacent circular locking holes 2, that is, the tangent line tangent to the circle is 270um.

Embodiment 2

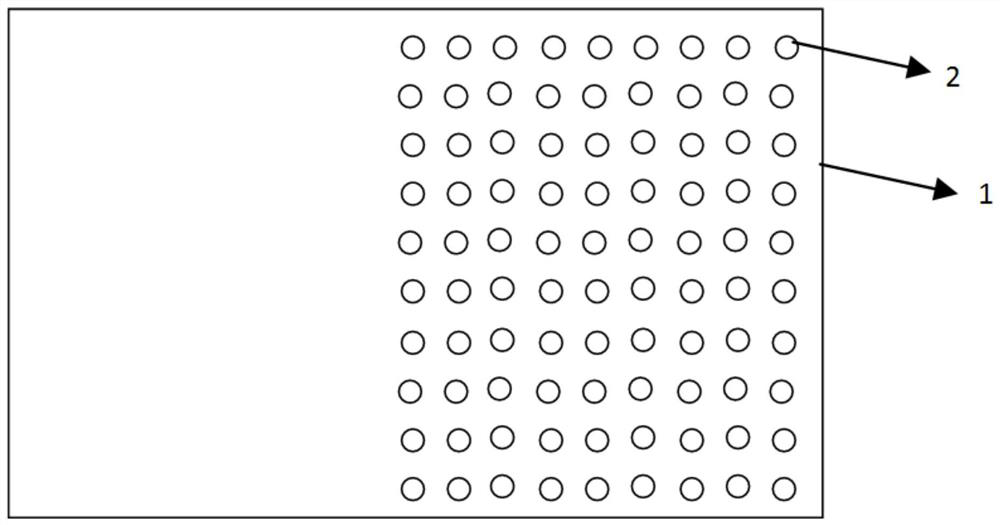

[0064] A kind of adhesive lock array lead frame of the present invention, as figure 2 As shown, the lead frame substrate 1 is rectangular, and its surface is provided with a glue-locking structure. The glue-locking structure is a circular glue-locking hole 2 distributed on half of the surface of the lead-frame substrate. The diameter is 30um, and the distance between the edges of two adjacent locking holes 2 is 207um.

Embodiment 3

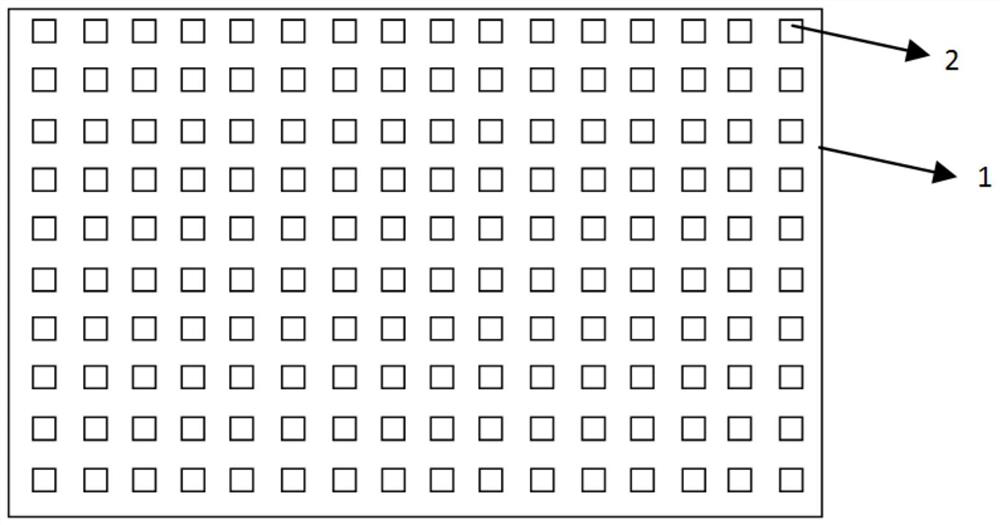

[0066] A kind of adhesive lock array lead frame of the present invention, as image 3 As shown, the lead frame substrate 1 is rectangular, and its surface is provided with a glue-locking structure. The glue-locking structure is a square glue-locking hole 2 evenly distributed on the lead-frame substrate, and the side length of the square glue-locking hole 2 is 80um. , the distance between the edges of two adjacent locking holes 2 is 400um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com