Lithium-rich manganese-based positive electrode material with aluminum-doped surface and titanium-aluminum-lithium phosphate-coated surface and preparation thereof

A lithium aluminum titanium phosphate and lithium-rich manganese-based technology, which is applied in the fields of energy storage materials and electrochemistry, can solve the problems of complicated operation, increased impedance, difficult industrialized production, etc., and achieves low preparation cost, inhibited phase transition, and easy industrialized production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

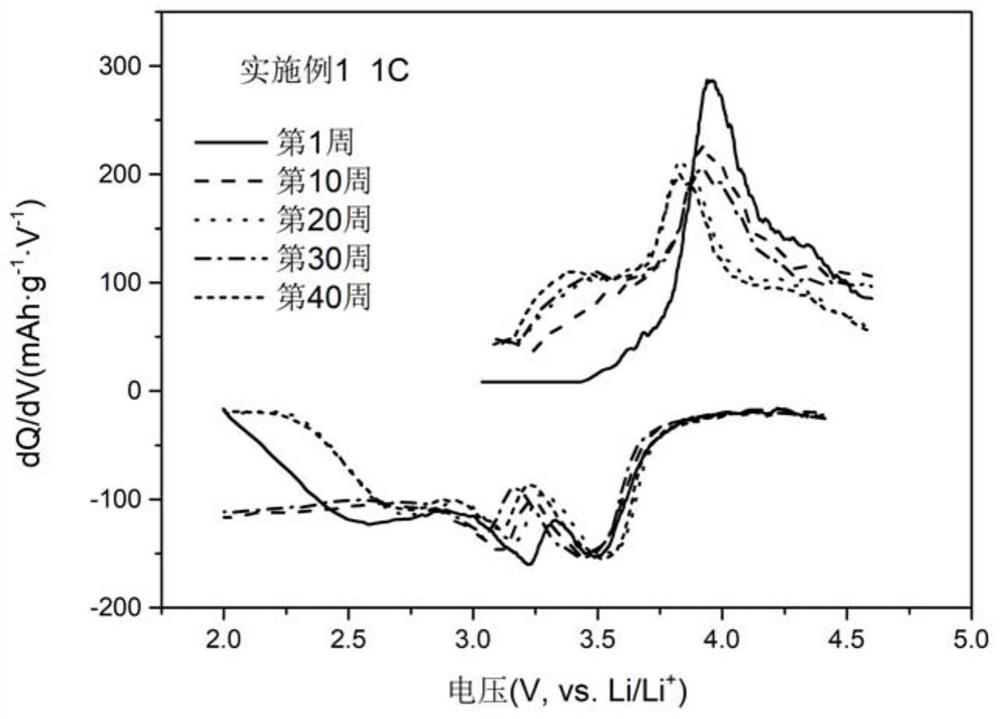

Embodiment 1

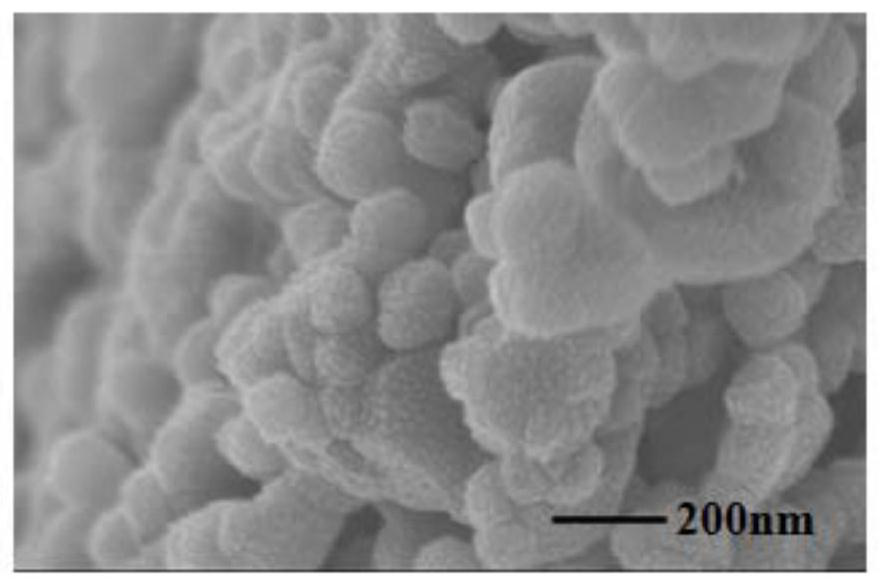

[0036] The two-step method of this embodiment synthesizes surface-coated Li 1.3 Al0.3 Ti 1.7 (PO 4 ) 3 and surface-doped modified Al Li 1.2 Ni 0.2 mn 0.6 o 2 , the specific preparation process is as follows:

[0037] 1. Add 0.0701gAl(NO 3 ) 3 9H 2 O was dissolved in 15ml of absolute ethanol, stirred until dissolved and 0.5g of bulk Li was added 1.2 Ni 0.2 mn 0.6 o 2 , ultrasonicated for half an hour, then placed on a magnetic stirrer, set the heating temperature to 70°C, and the stirring rate to 350r / min, evaporated the above solution to dryness, and then dried it in an oven at 80°C for 12h to obtain Al(NO 3 ) 3 9H 2 O-coated Li 1.2 Ni 0.2 mn 0.6 o 2 ;

[0038] 2. Place the dried powder in a muffle furnace, heat it to 600°C at a heating rate of 5°C / min and keep it for 5 hours to obtain a Li surface doped with Al. 1.2 Ni 0.2 mn 0.6 o 2 ;

[0039] 3. Add 15ml of absolute ethanol to the calcined powder, stir for half an hour, mix well, add dropwise absolu...

Embodiment 2

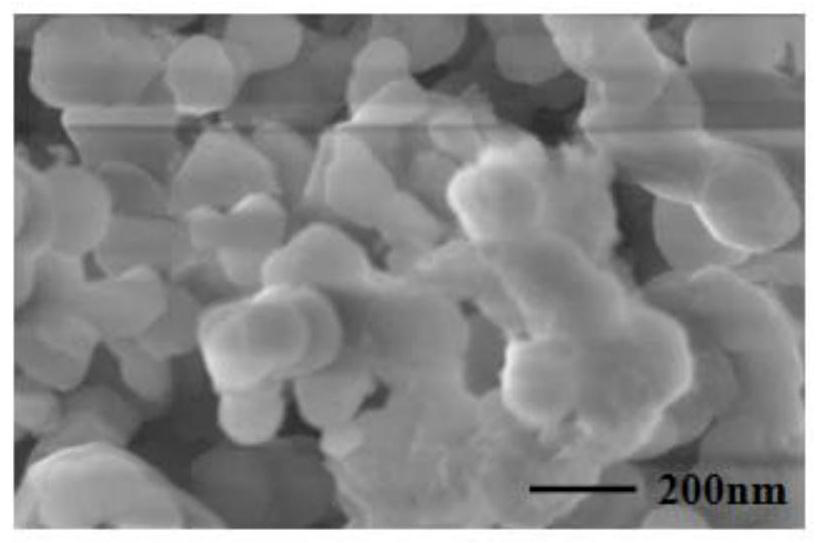

[0047] This embodiment synthesizes surface-coated Li by one-step method 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 and surface-doped modified Al Li 1.2 Ni 0.2 mn 0.6 o 2 , the specific preparation process is as follows:

[0048] 1. Add 0.0701gAl(NO 3 ) 3 9H 2 O was dissolved in 15ml of absolute ethanol, stirred until dissolved and 0.5g of bulk Li was added 1.2 Ni 0.2 mn 0.6 o 2 , ultrasonicated for half an hour, then placed on a magnetic stirrer, set the heating temperature to 70°C, and the stirring rate to 350r / min, evaporated the above solution to dryness, and then dried it in an oven at 80°C for 2h to obtain Al(NO 3 ) 3 9H 2 O-coated Li 1.2 Ni 0.2 mn 0.6 o 2 ;

[0049] 2. Add 15ml of absolute ethanol to the dried powder, stir for half an hour, mix thoroughly and add dropwise absolute ethanol in which 0.01g of tetrabutyl titanate is dissolved (tetrabutyl titanate is completely dissolved in absolute ethanol) , and then stirred for half an hour;

[0050] 3. Add 0.0009g...

Embodiment 3

[0057] This embodiment synthesizes surface-coated Li by one-step method 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 and surface layer doped modified Al Li 1.2 Ni 0.2 mn 0.6 o 2 , the specific preparation process is as follows:

[0058] 1. Add 0.0701gAl(NO 3 ) 3 9H 2 O was dissolved in 15ml of absolute ethanol, stirred until dissolved and 0.5g of bulk Li was added 1.2 Ni 0.2 mn0.6 o 2 , ultrasonicated for half an hour, then placed on a magnetic stirrer, set the heating temperature to 70°C, and the stirring rate to 350r / min, evaporated the above solution to dryness, and then dried it in an oven at 80°C for 2h to obtain Al(NO 3 ) 3 9H 2 O-coated Li 1.2 Ni 0.2 mn 0.6 o 2 ;

[0059] 2. Add 15ml of absolute ethanol to the dried powder, stir for half an hour, mix well, add dropwise absolute ethanol dissolved in 0.01g of tetrabutyl titanate, and then stir for half an hour;

[0060] 3. Add 0.0009gLiOH·H 2 O and 0.0053gNH 4 h 2 PO 4 Dissolve it with 5ml of ethanol and add it to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com