Organic silicon modified waterborne polyurethane waterproof coating and preparation method thereof

A water-based polyurethane and waterproof coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of poor mechanical properties, poor wear resistance and weather resistance, and poor storage stability of water-based polyurethane emulsion problem, to achieve the effect of good weather resistance, not easy to yellow, good elasticity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

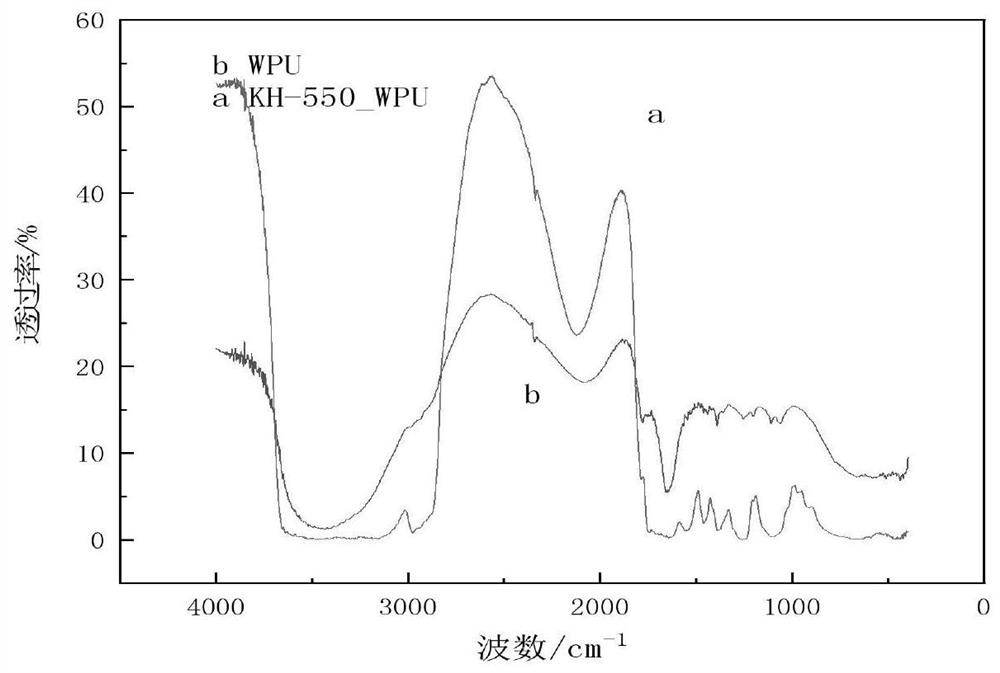

Image

Examples

preparation example Construction

[0054] The present invention also provides the preparation method of the organosilicon-modified water-based polyurethane waterproof coating described in the above technical scheme, comprising the following steps:

[0055] (1) Dewatering polyether polyol and polycarbonate polyol to obtain a polyol mixture, the temperature of the dewatering is 100-120°C;

[0056] (2) After cooling the polyol mixed solution obtained in the step (1) to 50-60° C., polyisocyanate and catalyst are added in turn to carry out prepolymerization to obtain the first prepolymer; the temperature of the prepolymerization is 75 ~80°C;

[0057] (3) adding a hydrophilic chain extender and a non-hydrophilic chain extender sequentially to the first prepolymer obtained in the step (2) to carry out the chain extension reaction, and stop heating when the isocyanate index reaches 1.1 to 1.2 to obtain The second prepolymer; the temperature of the chain extension reaction is 75-80°C;

[0058] (4) The temperature of t...

Embodiment 1

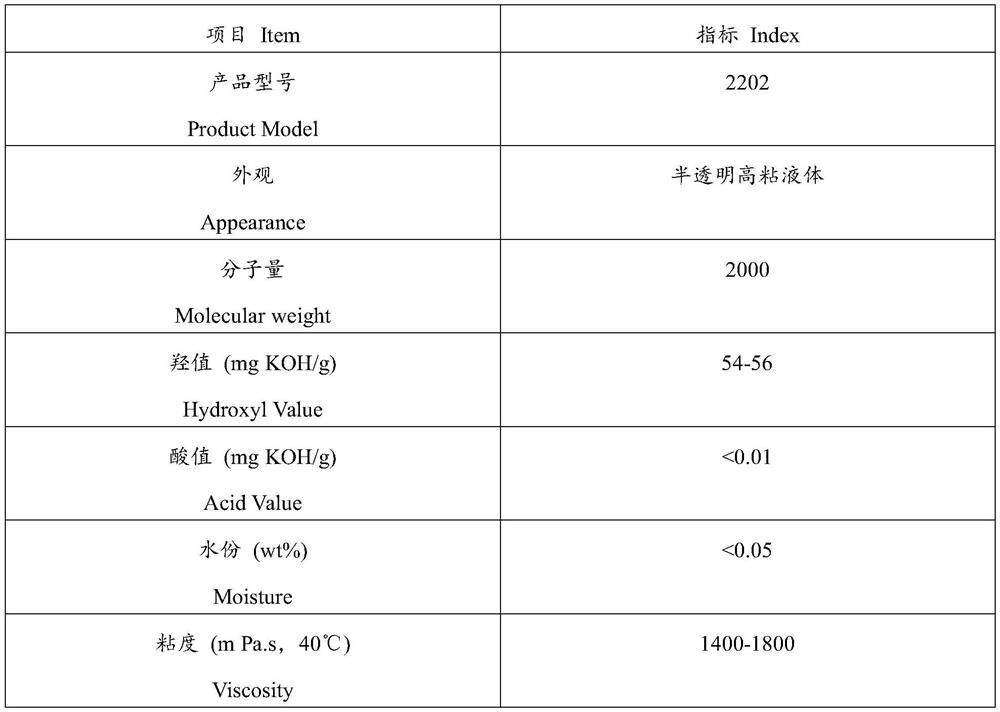

[0080] The formula of organosilicon-modified waterborne polyurethane waterproof coating is as shown in table 1:

[0081] Table 1: The formula of preparation example 1 organosilicon-modified waterborne polyurethane waterproof coating

[0082]

[0083]

[0084] Preparation:

[0085] (1) Polyether polyol and polycarbonate polyol are placed in a reaction kettle, and water is removed in vacuum at 100°C for 2 hours to obtain a polyol mixture;

[0086] (2) After cooling the polyol mixture obtained in step (1) to 50°C, add polyisocyanate to the reaction kettle, then raise the temperature to 80°C, and keep it warm for 1 hour; then add the catalyst to the reaction kettle and keep it warm 3h, obtain the first prepolymer;

[0087] (3) Add a hydrophilic chain extender to the reactor and keep it warm at 80°C for 1 hour; then add a post-chain extender to the reactor and react at 80°C for 1 hour, and stop heating when the isocyanate index reaches 1.1 to 1.2 , to obtain the second pre...

Embodiment 2

[0142] The difference from Example 1 is that the mass ratio of N210 / PPCD is 3:2, and the other components and preparation methods are the same as in Example 1.

[0143] In this example, when the mass ratio of N210 / PPCD is 3:2, the test results of the properties of the emulsion and the film are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com