A kind of nickel-based superalloy surface alcrsi slurry infiltration agent and preparation method thereof

A nickel-based superalloy, slurry technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problem of inappropriate slurry viscosity and pH, difficult to control the uniformity of the infiltration layer, and corrosion resistance. Insufficient and other problems, to achieve the effect of improving the uneven thickness of the coating, various forms of addition, and moderate aluminum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

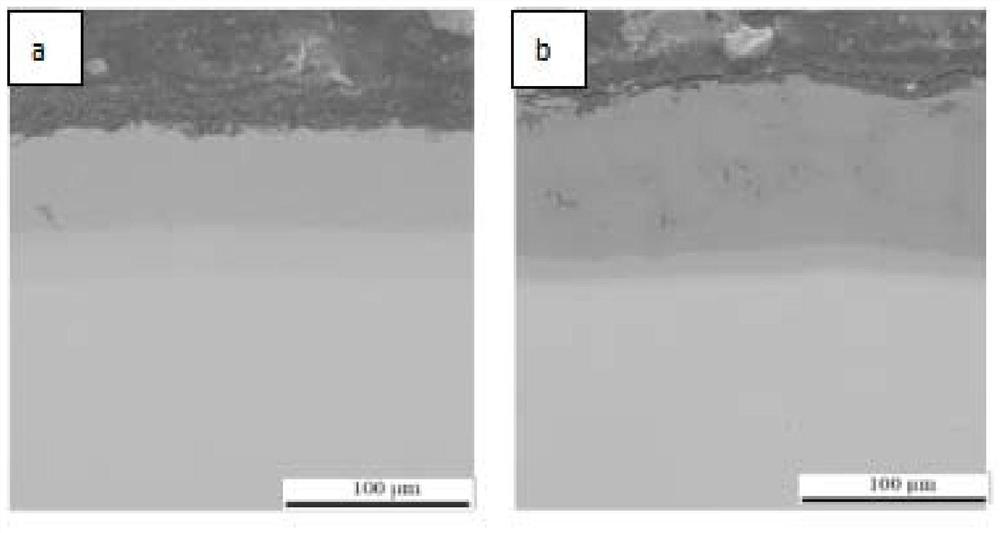

Image

Examples

Embodiment 1

[0032]First, in terms of mass fraction, prepare component A: 20%, component B: 40% and component C: 40% AlCrSi slurry infiltration agent on the surface of nickel-based superalloy; wherein, component A: 6% AlCl 3 , 6% NH 4 Cl, 10% Cr 2 o 3 and 24% H 3 PO 4 Solution (concentration 85%), the balance is dehydrated alcohol; Component B: 15% CrCl 3 , 30% Al 2 o 3 and 15% H 3 PO 4 solution (concentration 85%), the balance is absolute ethanol; component C: 60% spherical AlCr powder, 30% Si powder, and the balance is spherical Al powder, wherein the content of Al in the AlCrSi powder is 60%.

[0033] Fully mix the above components A, the mixing order is: first add AlCl to part of the absolute ethanol solution 3 , NH 4 Cl, Cr 2 o 3 、H 3 PO 4 solution (concentration 85%), after mixing, add the remaining part of absolute ethanol solution and mix evenly. Then add distilled water to dilute, adjust the component density, pH and viscosity to the required range, and filter after...

Embodiment 2

[0039] First, in terms of mass fraction, prepare component A: 20%, component B: 40% and component C: 40% AlCrSi slurry infiltration agent on the surface of nickel-based superalloy; wherein, component A: 6% AlCl 3 , 7% NH 4 Cl, 12% Cr 2 o 3 and 22% H 3 PO 4 Solution (concentration 85%), the balance is dehydrated alcohol; Component B: 16% CrCl 3 , 32% Al 2 o 3 and 12% H 3 PO 4 Solution (concentration 85%), the balance is absolute ethanol; Component C: 55% spherical AlCr powder, 32% Si powder, and the balance is spherical Al powder, wherein the content of Al in the AlCrSi powder is 60%;

[0040] Fully mix the above components A, the mixing order is: first add AlCl to part of the absolute ethanol solution 3 , NH 4 Cl, Cr 2 o 3 、H 3 PO 4 solution (concentration 85%), after mixing, add the remaining portion of absolute ethanol and mix evenly. After diluting with distilled water, adjust the component density, pH and viscosity to the required range, and filter after sta...

Embodiment 3

[0046] First, in terms of mass fraction, prepare component A: 20%, component B: 40% and component C: 40% AlCrSi slurry infiltration agent on the surface of nickel-based superalloy; wherein, component A: 7% AlCl 3 , 8% NH 4 Cl, 13% Cr 2 o 3 and 22% H 3 PO 4 Solution (concentration 85%), the balance is dehydrated alcohol; Component B: 17% CrCl 3 , 33% Al 2 o 3 and 12% H 3 PO 4 Solution (concentration 85%), the balance is absolute ethanol; component C: 55% spherical AlCr powder, 32% Si powder, and the balance is spherical Al powder, wherein the content of Al in the AlCrSi powder is 60%.

[0047] Fully mix the above components A, the mixing order is: first add AlCl to part of the absolute ethanol solution 3 , NH 4 Cl, Cr 2 o 3 、H 3 PO 4 solution (concentration 85%), after mixing, add the remaining portion of absolute ethanol and mix evenly. After diluting with distilled water, adjust the component density, pH and viscosity to the required range, and filter after sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com