Nickel-iron-nitrogen-doped carbon material trifunctional electrocatalyst based on zif-8 and its preparation method and application

A ZIF-8, electrocatalyst technology, applied in the field of electrochemical catalysis, can solve problems such as stability and catalytic activity to be improved, and achieve the effects of easy purchase and preparation, good catalytic activity, and good methanol tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing the electrocatalyst described in the above technical solution, comprising the following steps:

[0043] (1) Mix nickel foam and ferric salt in an organic solvent to undergo a redox reaction to obtain a redox product system;

[0044] (2) Mix the redox product system with zinc salt and 2-methylimidazole, and perform a hydrothermal reaction to obtain a NiFeZn-ZIF precursor;

[0045] (3) Carbonizing the NiFeZn-ZIF precursor to obtain the electrocatalyst.

[0046] The invention mixes the nickel foam and the ferric salt in an organic solvent to generate a redox reaction to obtain a redox product system.

[0047] In the present invention, the size of the nickel foam is preferably 2cm×1cm~0.5cm×1cm, more preferably 1cm×1cm; the nickel foam is preferably obtained by soaking commercially available nickel foam in acid, and the acid is preferably 3 mol / L hydrochloric acid solution; the acid soaking treatment is preferably carried out ...

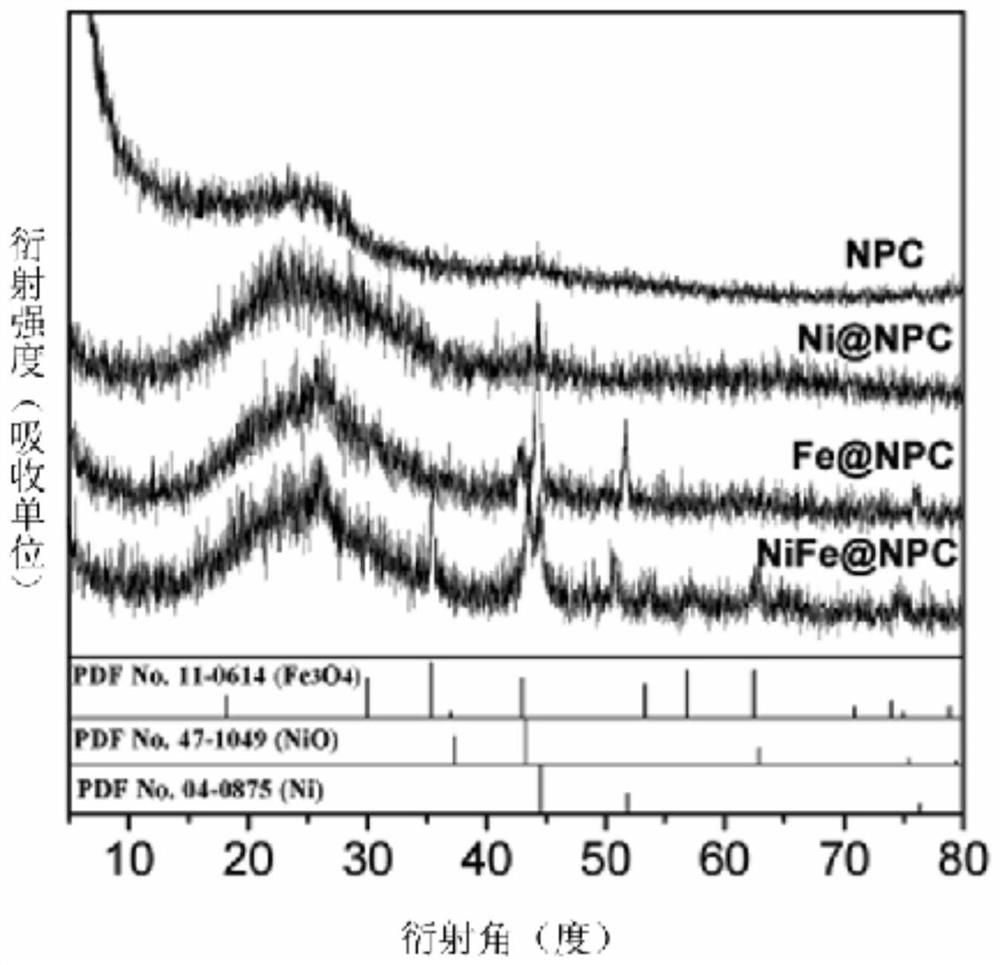

Embodiment 1

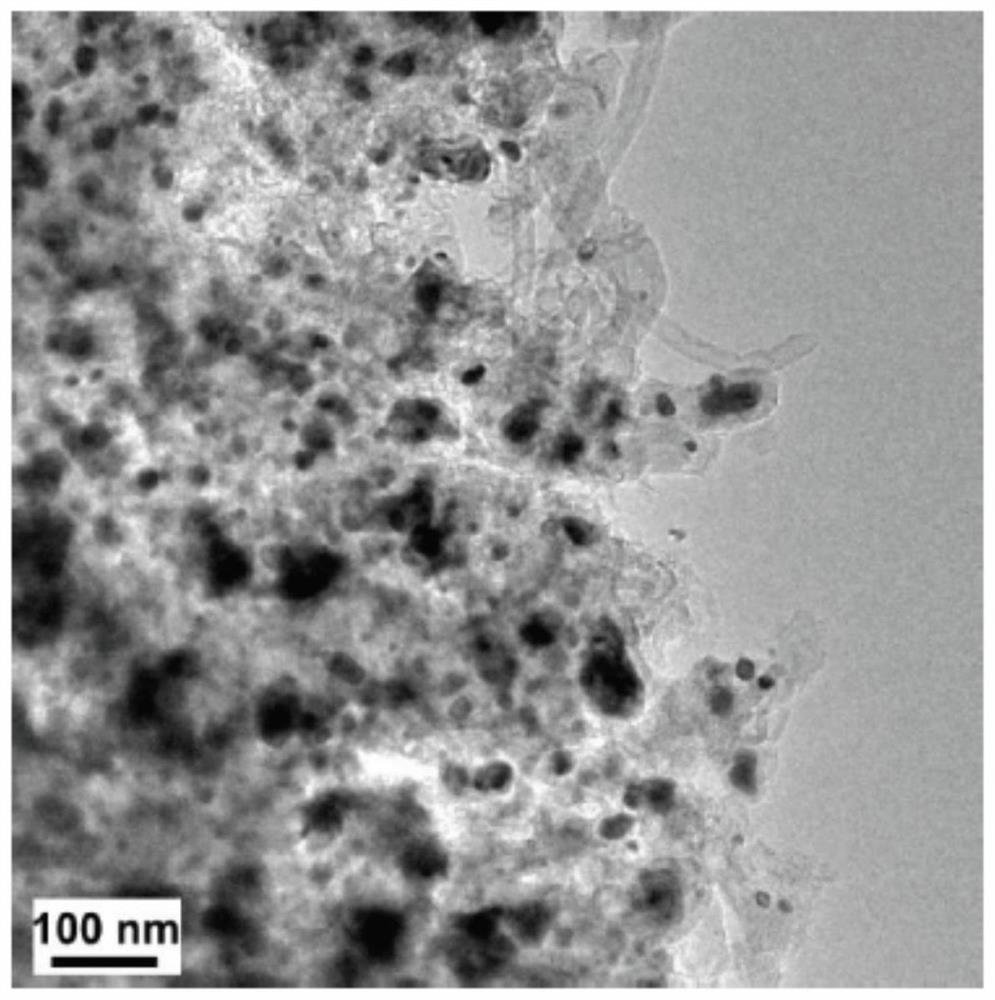

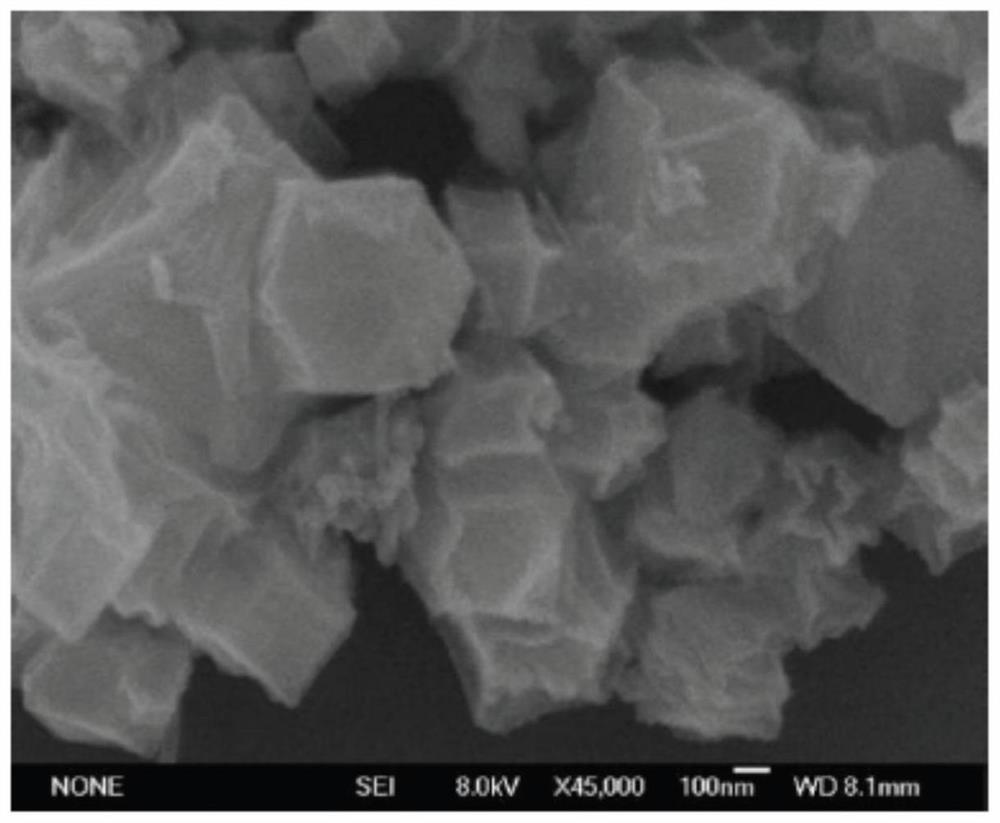

[0069] (1) Preparation of NiFeZn-ZIF

[0070] Take 5 commercially available nickel foams of 1cm×1cm and place them in a 3mol / L hydrochloric acid solution for 10 minutes of ultrasonication, take them out after ultrasonication, wash with deionized water and methanol three times and place them in a beaker; weigh 0.2g Fe(NO 3 ) 3 9H 2 O was placed in the above beaker, 30mL of methanol was added, stirred at 35°C for 2h; 1.2g of Zn(NO 3 ) 2 ·6H 2 O was placed in the above system and continued to stir to obtain a trimetallic solution; then 5.2g of 2-methylimidazole was weighed and dissolved in 40mL of methanol, and the resulting 2-methylimidazole solution was added dropwise to the above-mentioned metal at a rate of 22 μL / s. solution, and continue to stir for 0.5h. After the stirring is completed, transfer the solution to the reaction kettle, react at 150°C for 6h, centrifuge and wash with methanol three times, and vacuum-dry at 60°C for 24h. The obtained brownish-yellow solid is ...

Embodiment 2

[0074] The preparation method is basically the same as in Example 1, except that Fe(NO 3 ) 3 9H 2 The amount of O added was 0.6 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com