Phosphate glass reinforced 3D printing wire and preparation method thereof

A phosphate glass, 3D printing technology, applied in the field of material science, can solve the problems of retained filament, poor applicability of phosphate glass fiber, and limited glass transition temperature of phosphate glass fiber, etc., to expand the variety range, good mechanical properties and absorbability of the human body, to achieve the effect of individualized precision treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

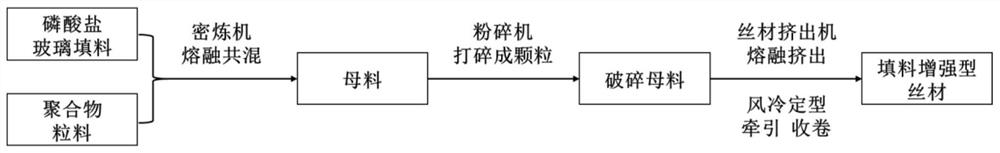

[0045] Example 1. Phosphate glass short fiber (20%)-L-polylactic acid wire (filler-reinforced wire prepared by indirect method)

[0046] According to the mass ratio of 1:4, weigh 60g of phosphate glass fiber (the average length of the glass fiber is 120μm) and 240g of L-polylactic acid pellets (the average particle size is about 5.0mm), and then place them in a blast oven at 80°C or Dry in a vacuum oven for 3 hours.

[0047] Add the dried phosphate glass fiber and L-polylactic acid into the mixing chamber of the internal mixer preheated to 200°C, keep it warm for 10 minutes, and then stir it at a rotor speed of 20 rpm for 10 minutes to obtain a masterbatch.

[0048] Cool the masterbatch to room temperature, and then crush it into plastic particles <5mm in a plastic shredder.

[0049] The plastic pellets were fed into a desktop single-screw wire extruder, wherein the extruder preheating zone temperature was 205°C, the working zone temperature was 210°C, and the screw speed was...

example 2

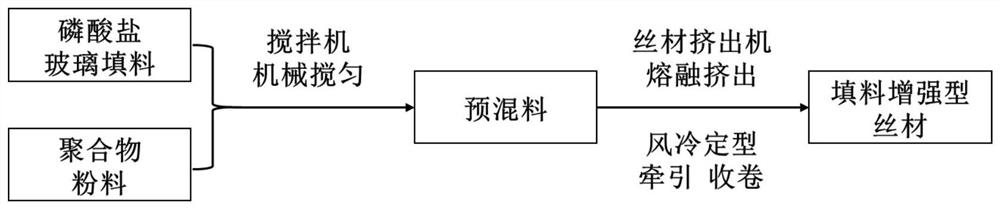

[0050] Example 2. Phosphate glass short fiber (20%) filler-L-polylactic acid filament (filler-reinforced filament prepared by direct method)

[0051] According to the mass ratio of 1:4, weigh 60g of phosphate glass fiber (the average length of glass fiber is 120μm) and 240g of L-polylactic acid powder (average particle size is about 0.8mm), and then place them in a blast oven at 80°C or Dry in a vacuum oven for 3 hours.

[0052] The difference from Example 1 is that the dried phosphate glass fiber and L-polylactic acid powder are added to a mixer for mechanical stirring to obtain a powdery premix.

[0053] The premix was added to a desktop single-screw wire extruder, wherein the temperature of the preheating zone of the extruder was 205° C., the temperature of the working zone was 210° C., and the screw speed was 30 rpm. The molten premix is extruded through a circular die with a diameter of 2.00mm / 3.00mm, and a 1000rpm fan is used to air-cool the extruded material to shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com