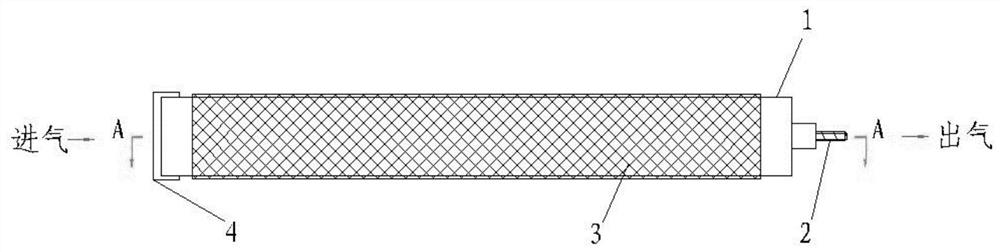

Double-dielectric-barrier low-temperature plasma synergistic catalytic treatment VOCs line pipe reaction unit

A technology of low-temperature plasma and synergistic catalysis, applied in gas treatment, separation methods, and separation of dispersed particles, etc., can solve the problems of large size and achieve the effects of small size, high reliability, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

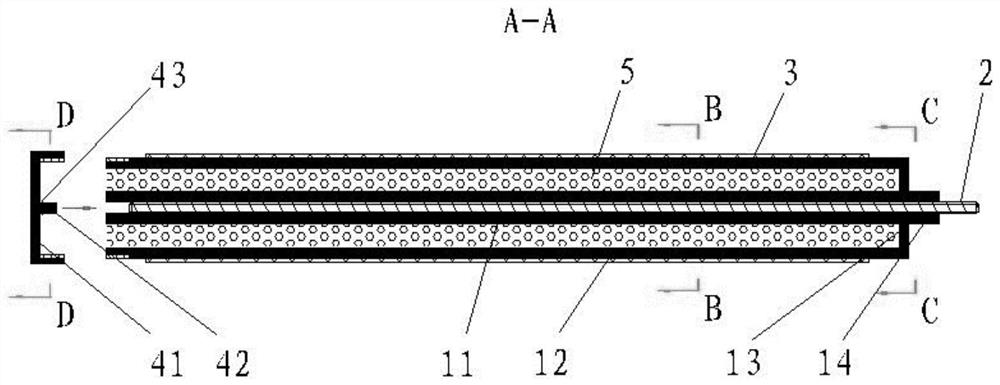

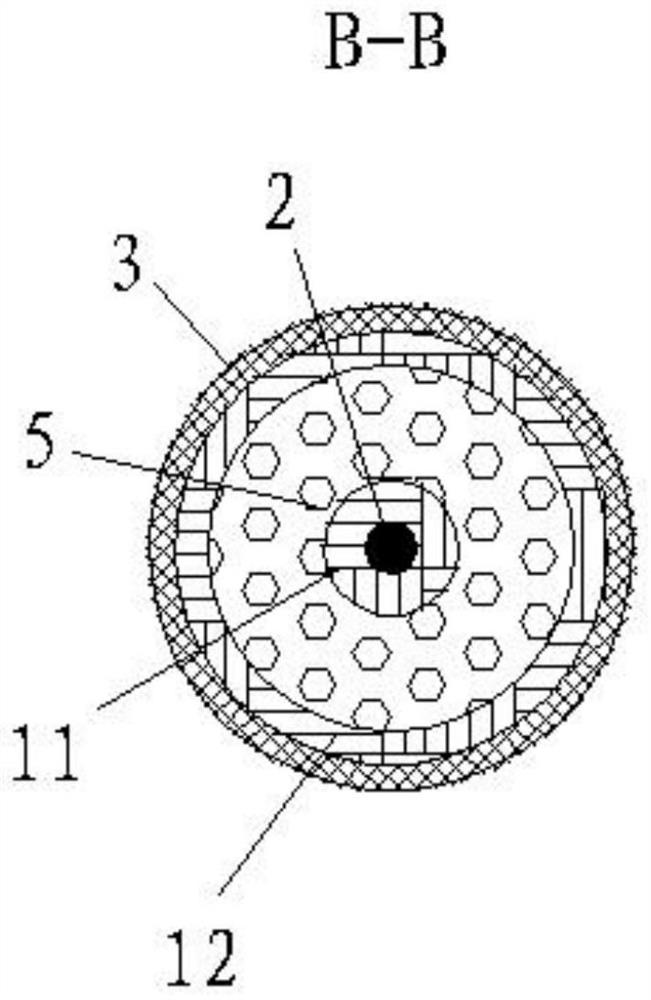

[0044] The structural design of the embodiment refers to the content of the invention, and the specific design parameters are as follows:

[0045] Insulation medium kit, the wall thickness is 2.5mm, the inner tube size is φ8.1x2.5mm, the outer tube size is φ25x2.5mm, the gas gap formed is 8.45mm, the tube length is 300mm, the internal thread size of the threaded seat is M3, The perforation size of the sealing plate is φ1mm. The material is C795 high-alumina porcelain, and the surface is coated with TiO 2 , the specific coating method is:

[0046] Use the water phase monodisperse nano TiO of model MZT-A1 2 Powder (3-5nm particle size), configured as an aqueous solution with a mass concentration of 0.8%. Put the cleaned insulating medium kit into the solution for dipping, pull it up to form a film, and cure it at 100°C after taking it out.

[0047] The inner electrode is M3 wire rod, and the material is stainless steel. The outer electrode is metal braided mesh, 16 mesh, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com