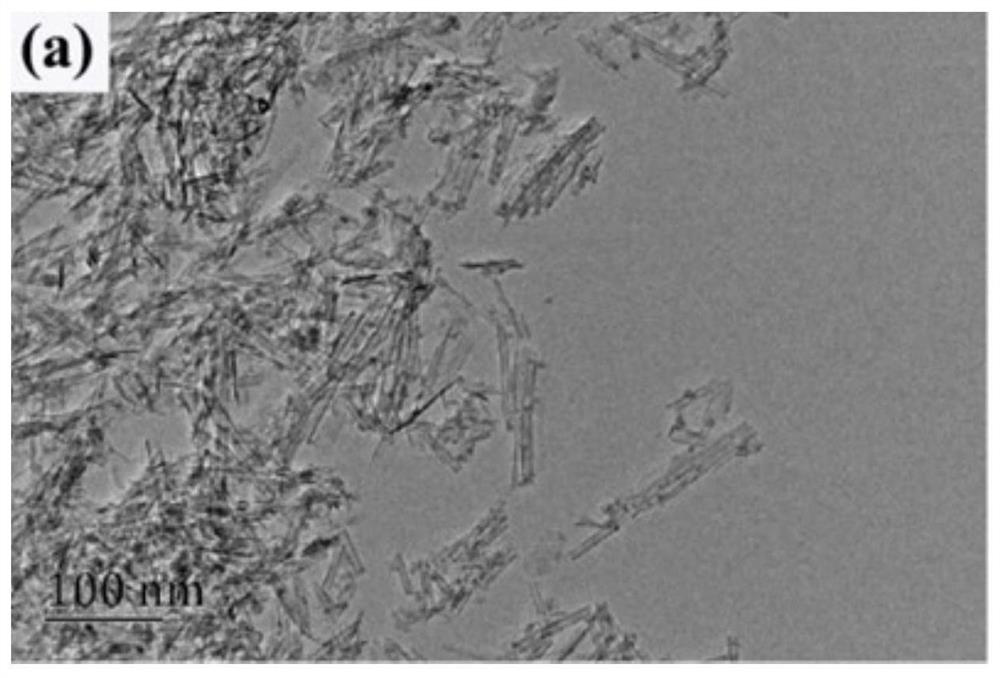

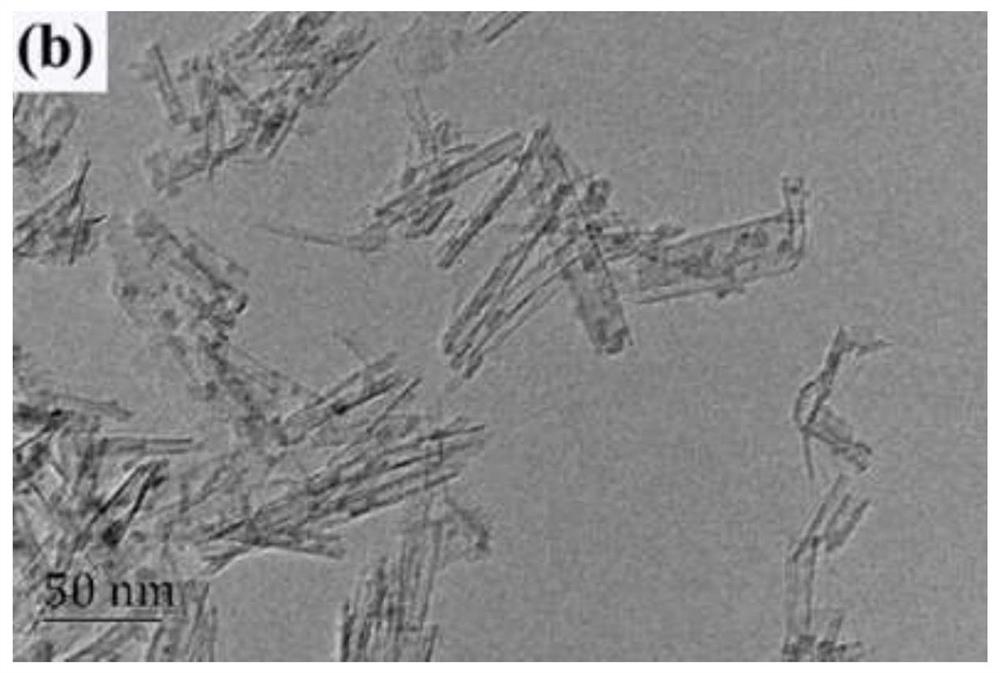

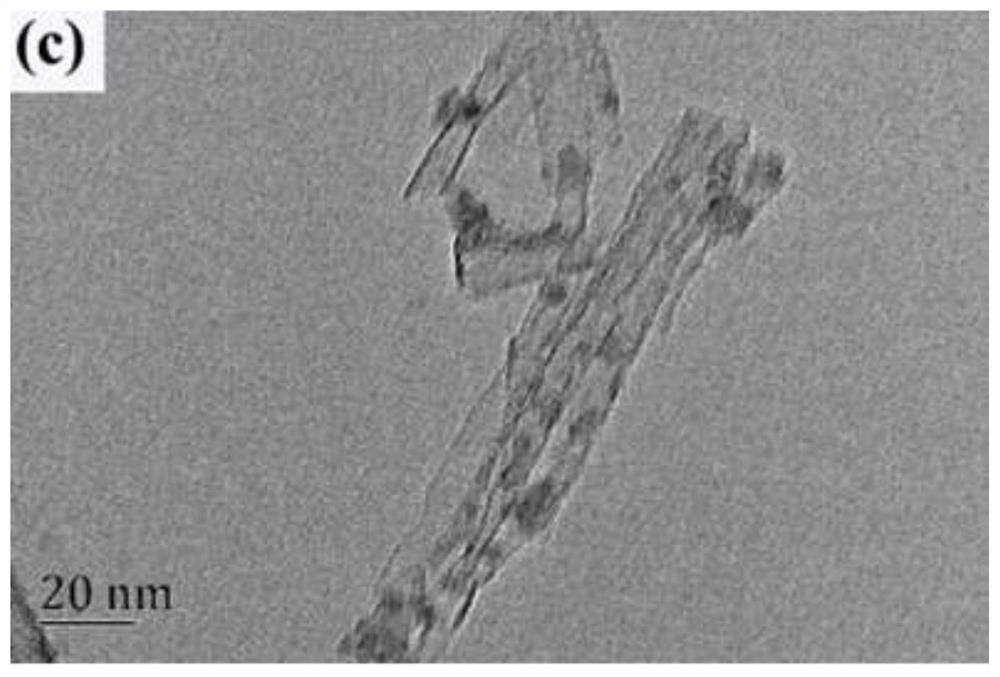

Preparation method of cadmium zinc sulfide-titanic acid nanotube composite photocatalyst

A technology of titanate nanotubes and composite photocatalysts, which is applied in chemical instruments and methods, catalyst activation/preparation, special compound water treatment, etc., can solve the problems of insufficient utilization rate and low separation efficiency of photogenerated electron-hole pairs, and achieve The effect of low cost, high adsorption and photocatalytic performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of cadmium zinc sulfide-titanic acid nanotube composite photocatalyst preparation method of the present invention, specifically implement according to the following steps:

[0043] Step 1. Weigh TiO 2 Add the nanometer powder into the NaOH solution, stir for 5 minutes, carry out hydrothermal reaction, cool to room temperature, and obtain sample A;

[0044] The concentration of NaOH solution is 5mol / L, TiO 2 The mass-to-body ratio of nanopowder to NaOH solution is 0.08g / 5mL;

[0045] The hydrothermal reaction condition is 140°C, and the time is 12h;

[0046] Step 2. Repeatedly washing sample A with deionized water until PH = 6, centrifuging to separate the precipitate, adding dilute hydrochloric acid to the precipitate for pickling for 0.5h, then washing with water, centrifuging, and drying again to obtain titanate nanotubes ;

[0047] The concentration of dilute hydrochloric acid is 0.01mol / L, and the volume is 20mL;

[0048] The drying temperature is 50-80°C;...

Embodiment 2

[0055] A kind of cadmium zinc sulfide-titanic acid nanotube composite photocatalyst preparation method of the present invention, specifically implement according to the following steps:

[0056] Step 1. Weigh TiO 2 Add the nanometer powder into the NaOH solution, stir for 25 minutes, carry out the hydrothermal reaction, cool to room temperature, and obtain the sample A;

[0057] The concentration of NaOH solution is 8mol / L, TiO 2 The mass-to-body ratio of nanopowder to NaOH solution is 1g / 25mL;

[0058] The hydrothermal reaction condition is 1480°C, and the time is 20h;

[0059] Step 2. Repeatedly washing sample A with deionized water until pH = 6.2, centrifuging to separate the precipitate, adding dilute hydrochloric acid to the precipitate for pickling for 1 hour, then washing with water, centrifuging, and drying again to obtain titanate nanotubes;

[0060] The concentration of dilute hydrochloric acid is 0.5mol / L, and the volume is 100mL;

[0061] The drying temperature...

Embodiment 3

[0068] A kind of cadmium zinc sulfide-titanic acid nanotube composite photocatalyst preparation method of the present invention, specifically implement according to the following steps:

[0069] Step 1. Weigh TiO 2 Add the nanometer powder into the NaOH solution, stir for 58 minutes, carry out hydrothermal reaction, cool to room temperature, and obtain sample A;

[0070] The concentration of NaOH solution is 10mol / L, TiO 2 The mass-to-body ratio of nanopowder to NaOH solution is 1g / 100mL;

[0071] The hydrothermal reaction condition is 150°C, and the time is 48h;

[0072] Step 2. Repeatedly washing sample A with deionized water until pH = 6.5, centrifuging to separate the precipitate, adding dilute hydrochloric acid to the precipitate for pickling for 3 hours, then washing with water, centrifuging, and drying again to obtain titanate nanotubes;

[0073] The concentration of dilute hydrochloric acid is 1mol / L, and the volume is 1000mL;

[0074] The drying temperature is 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com