Electroplating nickel-containing wastewater treatment and recovery method

A recovery method and technology for nickel wastewater, applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of increased treatment cost, unremoved metal ions, consumption, etc., and achieve improvement The effect of removing ability, improving adsorption exchange ability, and improving separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

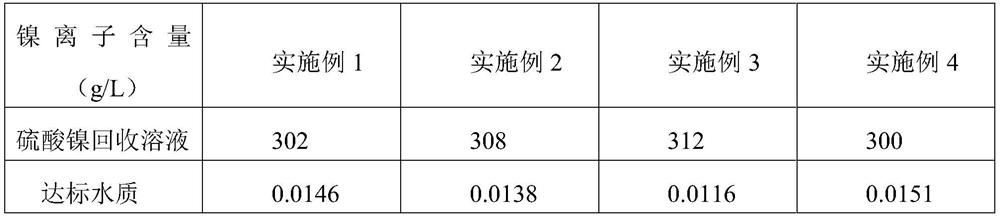

Embodiment 1

[0025] A method for treating and recycling electroplating nickel-containing wastewater, comprising the steps of:

[0026] S1. Pass the electroplating nickel-containing wastewater from bottom to top through the filter pipes provided with several sets of filter screens, and discharge it into the nickel-plating cleaning water tank;

[0027] S2. At a speed of 100r / min and a temperature of 35°C, pass carbon dioxide into the nickel-plating cleaning water tank at a flow rate of 0.08L / min, stir for 10 minutes, stop feeding carbon dioxide, and raise the temperature to 57°C and let stand for 30 minutes. Obtain the electroplating nickel-containing mixed turbid solution, then pass the electroplating nickel-containing mixed turbid solution through the bag filter at a flow rate of 0.4L / min, obtain the electroplating nickel-containing clear solution and discharge it into the buffer tank;

[0028] S3. Pass the electroplating nickel-containing clear liquid in the buffer tank through two sets o...

Embodiment 2

[0039] A method for treating and recycling electroplating nickel-containing wastewater, comprising the steps of:

[0040] S1. Pass the electroplating nickel-containing wastewater from bottom to top through the filter pipes provided with several sets of filter screens, and discharge it into the nickel-plating cleaning water tank;

[0041] S2. At a speed of 180r / min and a temperature of 28°C, pass carbon dioxide into the nickel-plating cleaning water tank at a flow rate of 0.05L / min, stir for 13 minutes, stop feeding carbon dioxide, and raise the temperature to 50°C and let stand for 34 minutes. Obtain the electroplating nickel-containing mixed turbid solution, then pass the electroplating nickel-containing mixed turbid solution through the bag filter at a flow rate of 0.5L / min, obtain the electroplating nickel-containing clear solution and discharge it into the buffer tank;

[0042] S3. Pass the electroplating nickel-containing clear liquid in the buffer tank through two sets o...

Embodiment 3

[0053] A method for treating and recycling electroplating nickel-containing wastewater, comprising the steps of:

[0054] S1. Pass the electroplating nickel-containing wastewater from bottom to top through the filter pipes provided with several sets of filter screens, and discharge it into the nickel-plating cleaning water tank;

[0055] S2. At a rotation speed of 240r / min and a temperature of 30°C, pass carbon dioxide into the nickel-plating cleaning water tank at a flow rate of 0.1L / min, stir for 16 minutes, stop feeding carbon dioxide, and raise the temperature to 54°C and let stand for 38 minutes. Obtain the electroplating nickel-containing mixed turbid solution, then pass the electroplating nickel-containing mixed turbid solution through the bag filter at a flow rate of 0.3L / min, obtain the electroplating nickel-containing clear solution and discharge it into the buffer tank;

[0056] S3. Pass the electroplating nickel-containing clear liquid in the buffer tank through tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com