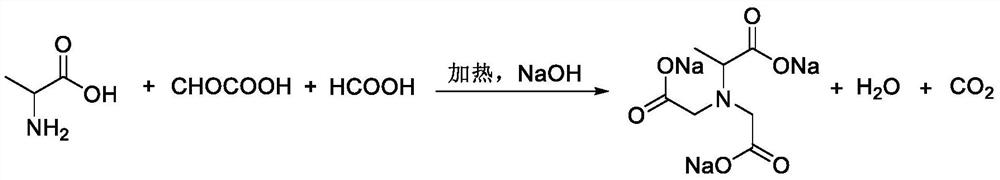

Preparation method of green chelating agent methyl glycine diacetic acid (MGDA) sodium salt

A technology of sodium methyl glycine diacetate and chelating agent is applied in the field of preparation of green chelating agent methyl glycine diacetate sodium salt, which can solve the problems of affecting chelating performance, high chloride ion content, strong corrosiveness, etc. The effect of production cost, simple reaction steps and short reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 4.5g of L-alanine and 10g of deionized water into a 100mL three-necked flask, stir at room temperature for 10min, then add 15.9g of glyoxylic acid (40wt%), control the reaction temperature of the solution at 30±2°C, React for 30 minutes. A reflux condenser was connected to the mouth of the three-necked flask, and the reaction temperature was raised to 95°C. Take 6.7g of formic acid with a mass fraction of 88% and put it in a constant pressure dropping funnel, control the opening of the glass stopper, slowly add formic acid dropwise, and control the reaction temperature at 95±2°C. After the dropwise addition, keep warm for 4h. The temperature was lowered to 75° C., and 32 wt % liquid caustic soda was added dropwise to the solution to adjust the pH to 10.0. Concentrate in vacuum at -0.01Mpa for 0.5h, and cool to room temperature. 30.1 g of methylglycine diacetic acid sodium salt solution was obtained, the mass concentration was 45%, the effective content was 40%, a...

Embodiment 2

[0029] Add 4.5g of L-alanine and 10g of deionized water into a 100mL three-necked flask, stir at room temperature for 10min, then add 18.5g of glyoxylic acid (40wt%), control the reaction temperature of the solution at 45±2°C, React for 30 minutes. A reflux condenser was connected to the mouth of the three-necked flask, and the reaction temperature was raised to 80°C. Take 9.2g of formic acid with a mass fraction of 88% and put it in a constant pressure dropping funnel, control the opening of the glass stopper, slowly add formic acid dropwise, and control the reaction temperature at 80±2°C. After the dropwise addition, keep warm for 3h. The temperature was lowered to 60° C., and 32 wt % liquid caustic soda was added dropwise to the solution to adjust the pH to 10.2. Concentrate in vacuum at -0.02Mpa for 0.5h, cool to room temperature, and obtain 29.3g of methylglycine diacetic acid sodium salt solution, with a mass concentration of 48%, an effective content of 45%, and a tot...

Embodiment 3

[0032] Add 4.5g of L-alanine and 10g of deionized water into a 100mL three-necked flask, stir at room temperature for 10min, then add 13.0g of formic acid (88wt%), control the reaction temperature of the solution at 25±2°C, and react for 30min . A reflux condenser was connected to the mouth of the three-necked flask, and the reaction temperature was raised to 80°C. Take 27.8g of glyoxylic acid with a mass fraction of 40% and put it into a constant pressure dropping funnel, control the opening of the glass stopper, slowly add glyoxylic acid dropwise, and control the reaction temperature at 80±2°C. After the dropwise addition, keep warm for 5h. The temperature was lowered to 50° C., and 50 wt % liquid caustic soda was added dropwise to the solution to adjust the pH value to 11.0. Concentrate in vacuum at -0.03Mpa for 0.5h, cool to room temperature, and obtain 28.5g of methylglycine diacetic acid sodium salt solution, with a mass concentration of 48%, an effective content of 46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com