Wire rod coating material, and preparation method and application thereof

A technology of outer quilt and wire, applied in the field of wire, can solve the problems of easy aging, yellowing and brittleness of polyvinyl chloride, unsuitable for long-term close wearing, affecting the service life of earphone cables, etc., achieving low recycling cost and being conducive to environmental protection , The effect of not easy to age, yellow and become brittle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

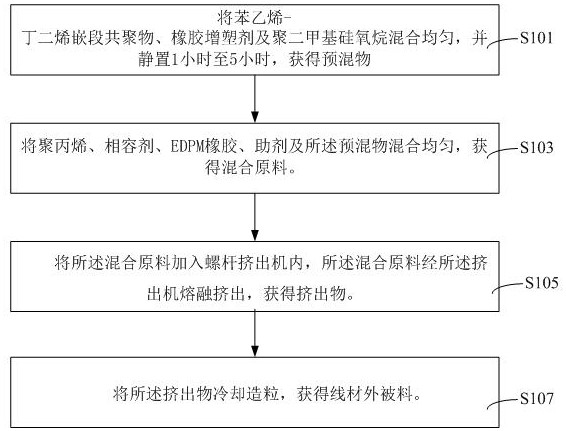

[0031] In one of the embodiments, the preparation method of the wire coating includes part or all of the following steps.

[0032] S101, mixing the styrene-butadiene block copolymer, rubber plasticizer and polydimethylsiloxane evenly, and standing for 1 hour to 5 hours to obtain a premix.

[0033] Specifically, the raw material of the styrene-butadiene block copolymer is a powdery solid, the polydimethylsiloxane is an oily liquid, and the rubber plasticizer is also an oily liquid. In one embodiment, the rubber plasticizer is paraffin grade industrial base oil. Since both polydimethylsiloxane and rubber plasticizer are oily liquids, it can be understood that the powder of styrene-butadiene block copolymer is affected by the oily surface tension without processing. It is easy to float on the oily surface of polydimethylsiloxane and rubber plasticizer, that is, the three cannot be mixed evenly. This will directly lead to floating powder on the surface of the finished outer cove...

Embodiment 1

[0048] The preparation process of the wire rod outer covering material of the present embodiment is as follows:

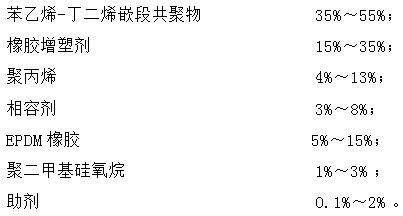

[0049] (1) Raw materials, according to mass percentage, raw materials include 40% styrene-butadiene block copolymer, 30% rubber plasticizer, 10% polypropylene, 5% maleic anhydride graft compatibilizer, 12% EPDM Rubber, 1% polydimethylsiloxane, 1% antioxidant, 1% anti-ultraviolet agent.

[0050] (2) Put styrene-butadiene block copolymer, rubber plasticizer and polydimethylsiloxane into a mixer and mix evenly. The stirring speed is 200 rpm, and the stirring time is 30 minutes. After the stirring was completed, it was left to stand for 5 hours to obtain a premix.

[0051] (3) Add polypropylene, compatibilizer, EDPM rubber, antioxidant and anti-ultraviolet agent to the mixing tank. Stir at 500 rpm for 8 minutes to obtain a mixed raw material, and preheat the mixed raw material to 80°C.

[0052] (4) Put the mixed raw materials into the twin-screw extruder. Wherein, ...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is:

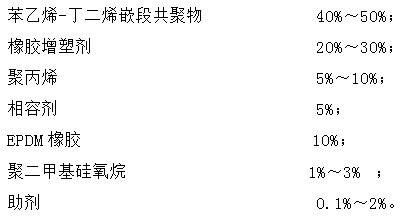

[0056] (1) Raw materials, according to mass percentage, raw materials include 45% styrene-butadiene block copolymer, 26% rubber plasticizer, 10% polypropylene, 5% maleic anhydride graft compatibilizer, 10% EPDM Rubber, 2% polydimethylsiloxane, 1% antioxidant, 1% anti-ultraviolet agent.

[0057] (4) The rotating speed of the main engine is 500 rpm, and the residence time in the main engine is less than that in Example 1.

[0058] Other steps are all the same as in Example 1, and sample 2 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com