Carbon-coated nickel sulfide electrode material and preparation method and application thereof

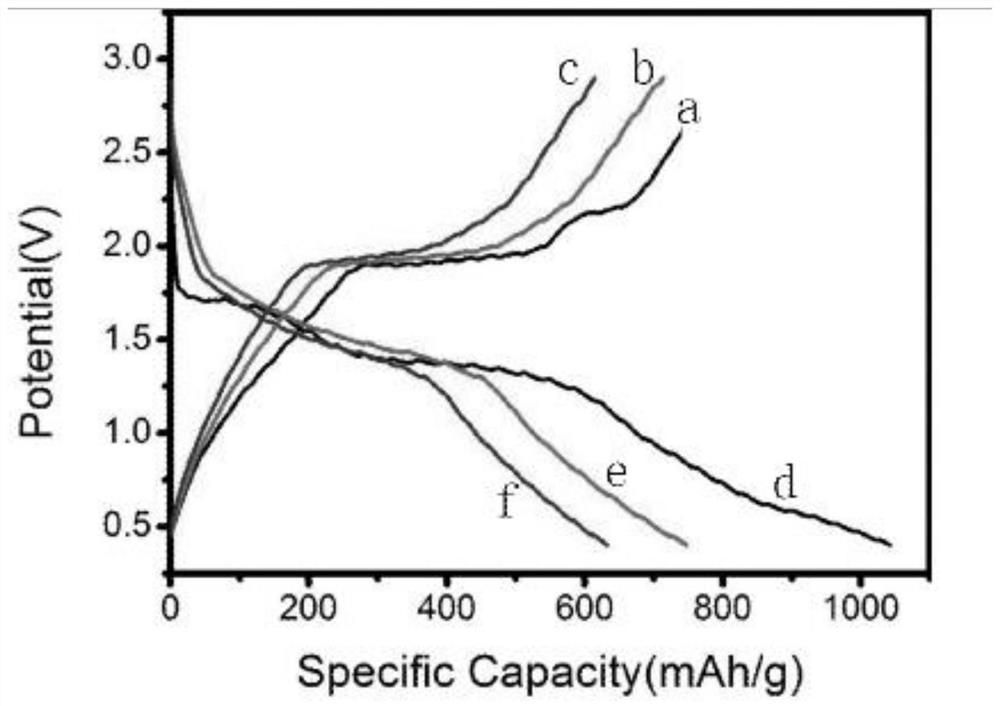

An electrode material, a technology of nickel sulfide, applied in the field of carbon-coated nickel sulfide electrode materials and its preparation, can solve the problems of poor reversible capacity and rate performance, inability to guarantee structure and electrochemical stability, poor conductivity, etc., and achieve charging and discharging Good capacity and rate performance, high reproducibility, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] One aspect of the present invention provides a method for preparing a carbon-coated nickel sulfide electrode material. In an exemplary embodiment of the preparation method of the carbon-coated nickel sulfide electrode material of the present invention, the preparation method may include:

[0024] S01, prepare ethylene glycol aqueous solution. Measure a predetermined amount of ethylene glycol solution and disperse it in deionized water, and stir evenly to obtain an ethylene glycol aqueous solution. The volume of ethylene glycol and aqueous solution can be mixed according to the ratio of 1:(0.75~1.25), for example, it can be mixed according to the volume ratio of 1:1. The amount of ethylene glycol added can be determined according to the sulfur source added, the amount of sulfur source and glucose used. For example, it is sufficient that the added nickel source, sulfur source and glucose can be completely dissolved. Of course, ethylene glycol can also be added in exces...

example 1

[0041] Step 1, measure 40 mL of ethylene glycol solution and disperse it in 40 mL of deionized water, stir until uniform to form a uniform mixed solution.

[0042] Step 2, slowly add 1.5 g of glucose to the solution obtained in Step 1, and stir until completely dissolved.

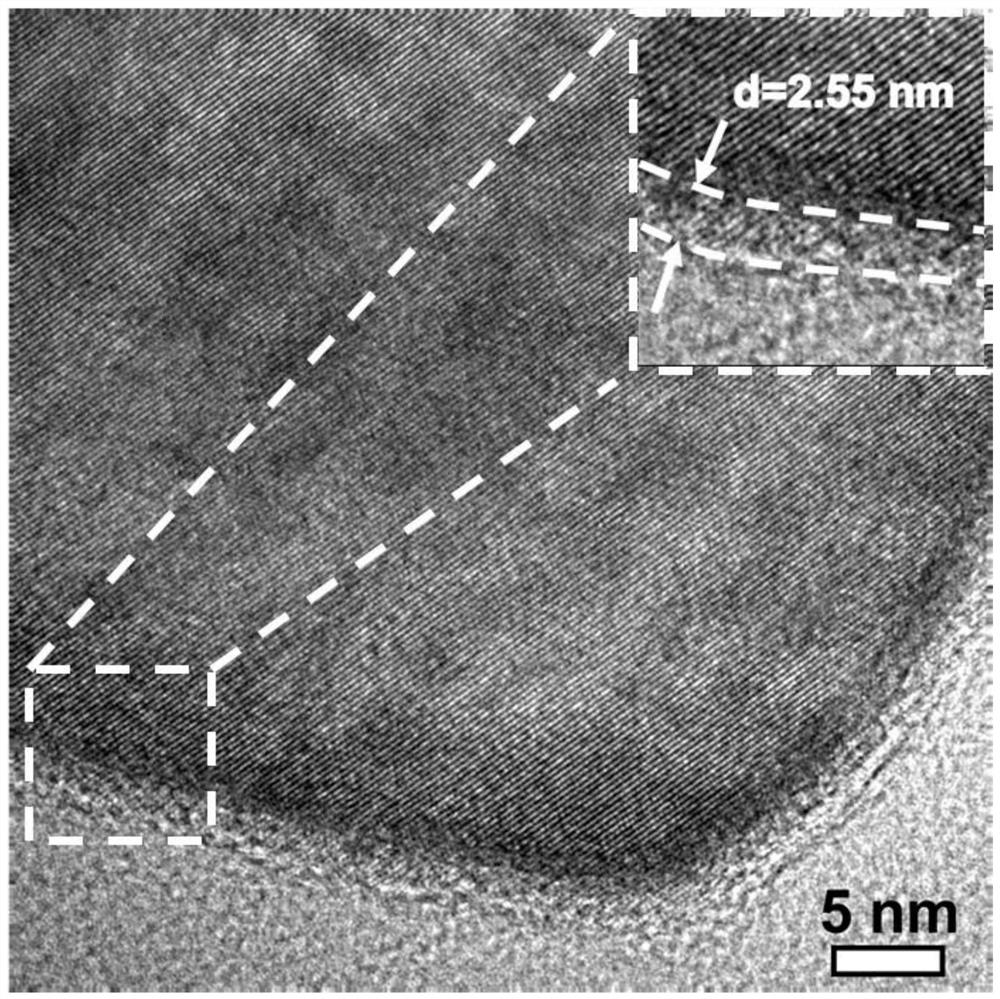

[0043] Step 3, slowly add 2 mmol of nickel acetate tetrahydrate (C 4 h 6 o 4 Ni·4H 2 O) Powder, magnetically stirred until completely dissolved; then 6 mmol of Na was added at a rate of 0.4 g / min 2 S 2 o 3 ·5H 2 O, stir magnetically until completely dissolved. The resulting solution was placed in a high-pressure reactor, heated in an oven at 180°C for 10 hours, and the resulting product was repeatedly washed and centrifuged with deionized water and absolute ethanol until it was clean, and finally dried in a vacuum oven to obtain NiS 2 Material. The resulting product was placed in a tube furnace N 2 In the atmosphere, calcined at 600 ° C for 4 hours to obtain a similar NiS / C (carbon-coated nickel s...

example 2

[0058] Step 1, measure 30 mL of ethylene glycol solution and disperse it in 50 mL of deionized water, stir until uniform to form a uniform mixed solution.

[0059] Step 2, slowly add 0.5 g of glucose to the solution obtained in Step 1, and stir until completely dissolved.

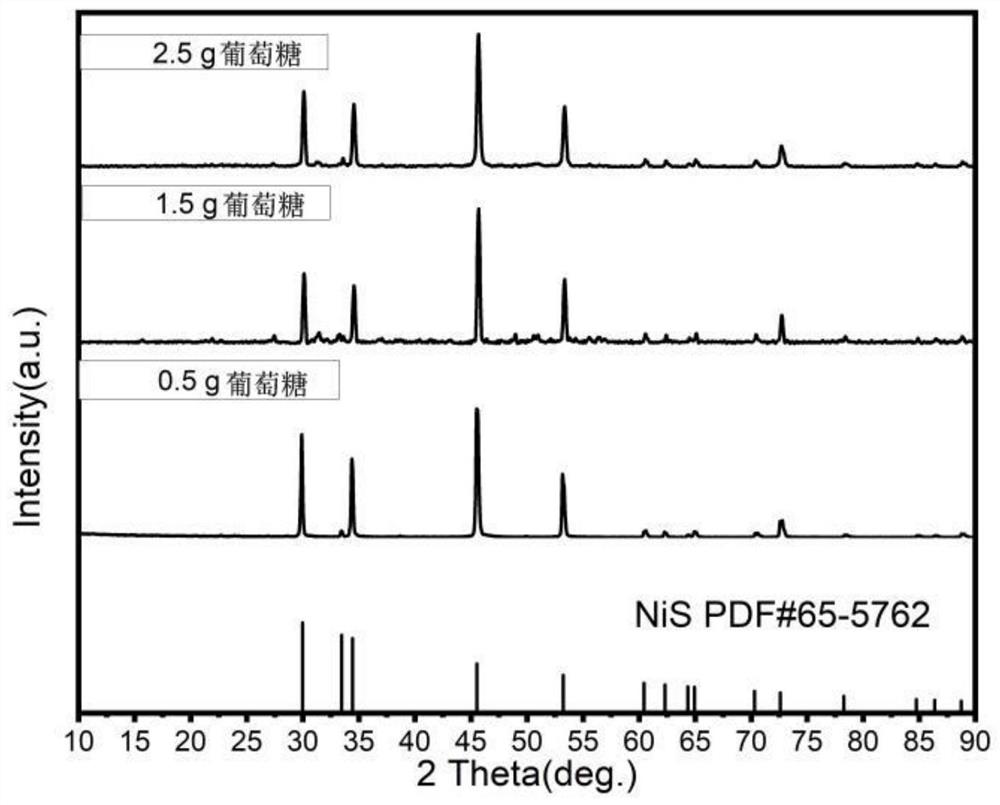

[0060] Step 3, slowly add 2 mmol of nickel acetate tetrahydrate (C 4 h 6 o 4 Ni·4H 2 O) powder, stirred magnetically until completely dissolved; then added 6 mmol of Na 2 S 2 o 3 ·5H 2 O, stir magnetically until completely dissolved. The resulting solution was placed in a high-pressure reactor, heated in an oven at 200°C for 24 hours, and the resulting product was repeatedly washed and centrifuged with deionized water and absolute ethanol until it was clean, and finally dried in a vacuum oven to obtain NiS 2 Material. The obtained product was placed in an Ar atmosphere in a tube furnace, and calcined at 500 ° C for 1 hour to obtain a similar NiS / C electrode material, and its XRD pattern is as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com