Foam concrete formula and preparation method and application thereof

A foamed concrete and formula technology, applied in the field of foamed concrete, can solve the problems of affecting the thermal insulation performance of foamed concrete, affecting the porosity of foamed concrete, low foam stability, etc., so as to improve the adhesion effect, improve the water penetration resistance, and improve the foam stability. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of foam concrete formula and preparation method:

[0068] S1. Add 1900g TPU particles, 400g tea saponin, 100g octadecyldimethyl benzyl ammonium chloride, 100g polyacrylamide, 50g hydroxymethyl starch ether and 5000g water into the first mixing tank, and use a mixer to Stir at a speed of 450r / min until bubbles are generated, and continue stirring for 5 minutes to obtain a foam solution;

[0069] S2. Add 5000g of fly ash, 10000g of shale ceramsite and 5000g of expanded vermiculite into the second mixing tank, stir with a mixer at a speed of 80r / min for 5min, then add 10000g of cement, and continue stirring for 2min to obtain a concrete slurry;

[0070] S3. Add the foam solution obtained in step S2 into the second mixing tank, mix the foam solution with the concrete slurry, stir with a mixer at a speed of 80 r / min for 1 min, and set aside.

Embodiment 2~ Embodiment 5

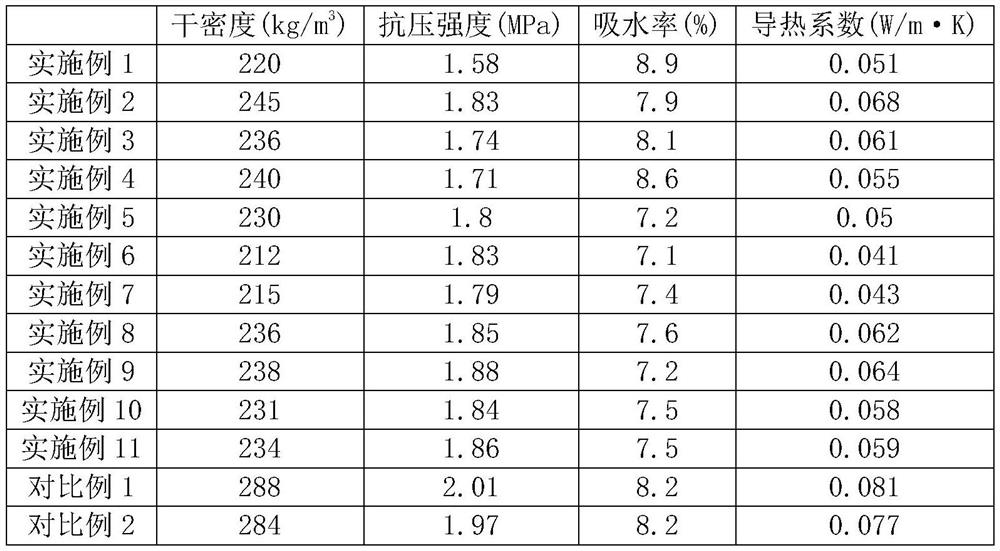

[0072] The difference between Embodiment 2 to Embodiment 5 and Embodiment 1 lies in the proportioning of raw materials, the stirring speed and the stirring time, as shown in Table 1.

[0073] Table 1

[0074] Example 2 Example 3 Example 4 Example 5 cement (g) 13000 11500 10500 11000 Shale ceramsite (g) 15000 12000 13125 11330 Expanded vermiculite (g) 5000 4000 4375 5670 Fly ash (g) 4000 3000 3800 3500 TPU particles (g) 800 3000 1000 1200 Tea saponin (g) 400 600 1000 500 Octadecyl dimethyl benzyl ammonium chloride (g) 200 200 200 200 Polyacrylamide (g) 200 300 400 200 Hydroxymethyl starch ether (g) 30 40 20 30 water (g) 8000 6500 5500 5500 Stirring speed in S1 (r / min) 450 500 500 450 Stirring time in S1 (min) 5 8 10 8 Stirring time before adding cement in S2 (min) 8 8 5 5 Stirring time after adding cement in S2 (min) 3 4 4 3 Stirring ...

Embodiment 6

[0076] The only difference between this example and Example 5 is that before step S1, a pretreatment step of TPU particles is also included. Oxygen was pre-mixed, then 1200g TPU particles, 1500g sodium dodecylbenzenesulfonate, 60g chloroplatinic acid and 10000g water were added to the reaction kettle, stirred at room temperature for 10min, and tridecafluoro was added dropwise into the reaction kettle The mixture of octyltrimethoxysilane and octamethylcyclotetrasiloxane, add dropwise within 1h, then stir at 60°C for 1h, then filter, collect the solid, wash the solid with water, and dry in an oven at 60°C 1h, the pretreated TPU particles were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com