Electrolyte for ultrahigh-voltage aluminum electrolytic capacitor as well as preparation method and application thereof

A technology of aluminum electrolytic capacitors and electrolytes, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of short life, restricting high stability, long-life high-voltage aluminum electrolytic capacitors, and large leakage current, so as to ensure long life. , high stability, the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

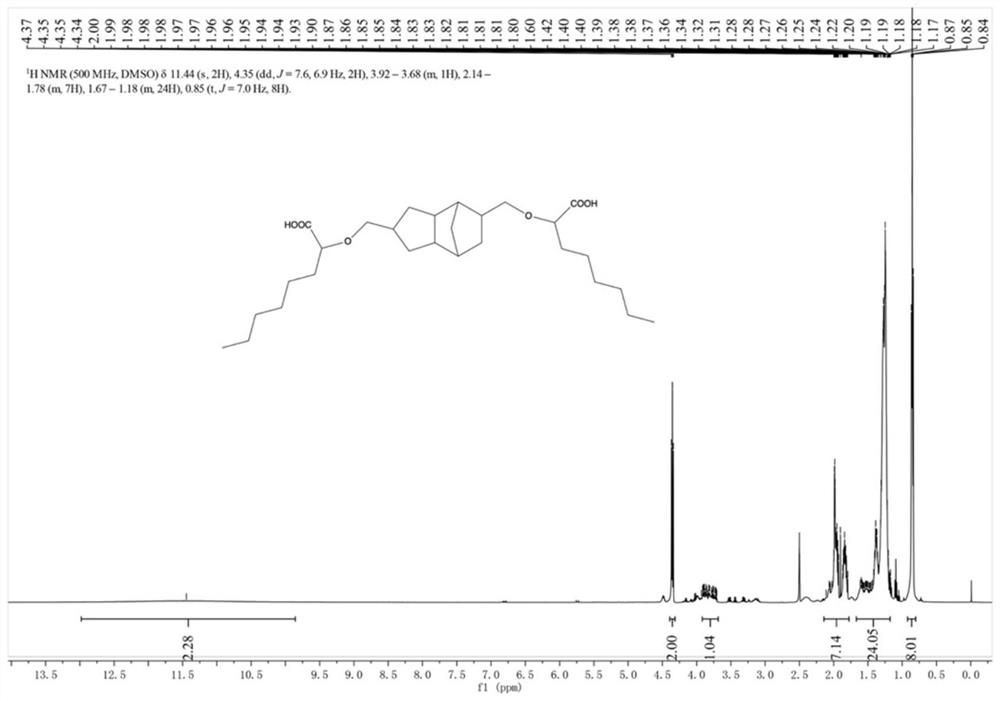

[0040] Mix (octahydro-1H-4,7-methyleneindene-2,5-diyl)dimethanol with a molar ratio of 1:2 and Na wire at 25°C under N 2 Reaction under protection for 4h, obtained (octahydro-1H-4,7-methyleneindene-2,5-diyl) sodium dimethoxide.

[0041] Mix the above (octahydro-1H-4,7-methyleneindene-2,5-diyl)sodium dimethoxide and 2-bromooctanoic acid ethyl ester at a molar ratio of 1:2, and reflux at 25°C for 6h , to obtain the ester of the final product.

[0042] Add 30ml of deionized water to the reaction solution, and add an equivalent of 1mol / L NaOH solution to convert the ester of the target product into a sodium salt, and then add phosphoric acid dropwise to adjust the pH value of the solution to 3-5. At this time, the target product consists of three fats The sodium salt of cyclodimethoxydioctanoic acid becomes tri-aliphatic cyclodimethoxydioctanoic acid; 30ml ethyl acetate is added to the above reaction solution to extract the target product from the water layer, separate the ester ...

Embodiment 2

[0049] (Octahydro-1H-4,7-methyleneindene-2,5-diyl)dimethanol with a molar ratio of 1:2 was mixed with Na wire at 32°C under N 2 Reaction under protection for 4h, obtained (octahydro-1H-4,7-methyleneindene-2,5-diyl) sodium dimethoxide.

[0050] Mix the above (octahydro-1H-4,7-methyleneindene-2,5-diyl)sodium dimethoxide and 2-bromooctanoic acid ethyl ester at a molar ratio of 1:2, and reflux at 32°C for 6h , to obtain the ester of the final product.

[0051] Add 30ml of deionized water to the reaction solution, and add an equivalent of 1mol / L NaOH solution to convert the ester of the target product into a sodium salt, and then add phosphoric acid dropwise to adjust the pH value of the solution to 3-5. At this time, the target product consists of three fats The sodium salt of cyclodimethoxydioctanoic acid becomes tri-aliphatic cyclodimethoxydioctanoic acid; 30ml ethyl acetate is added to the above reaction solution to extract the target product from the water layer, separate the...

Embodiment 3

[0055] Mix (octahydro-1H-4,7-methyleneindene-2,5-diyl)dimethanol with a molar ratio of 1:2 and Na wire at 20°C under N 2 Reaction under protection for 8h, obtained (octahydro-1H-4,7-methyleneindene-2,5-diyl) sodium dimethoxide.

[0056] Mix the above (octahydro-1H-4,7-methyleneindene-2,5-diyl)sodium dimethoxide with 2-bromooctanoic acid ethyl and propyl ester at a molar ratio of 1:2, and reflux at 20°C After 10 hours of reaction, the ester of the final product was obtained.

[0057] Add 30ml of deionized water to the reaction solution, and add an equivalent of 1mol / L NaOH solution to convert the ester of the target product into a sodium salt, and then add phosphoric acid dropwise to adjust the pH value of the solution to 3-5. At this time, the target product consists of three fats The sodium salt of cyclodimethoxydioctanoic acid becomes trialiphatic cyclodimethoxydioctanoic acid; 20ml ethyl acetate is added to the above reaction solution to extract the target product from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com