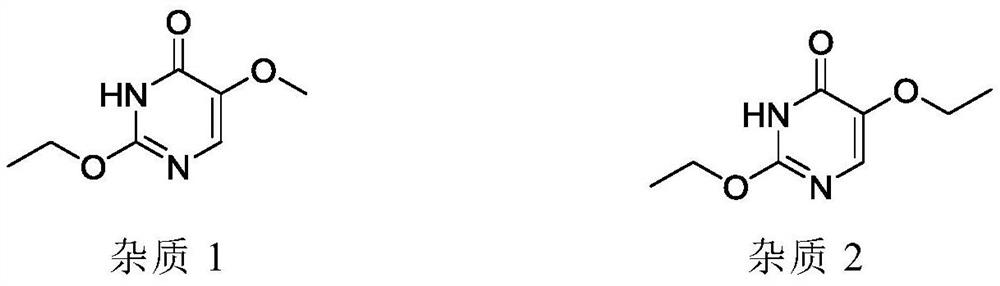

Preparation method of 2-ethoxy-5-fluorouracil impurity

A technology of fluorouracil and ethoxy, applied in the field of drug synthesis, can solve the problems of no public data report, etc., and achieve the effects of short route, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

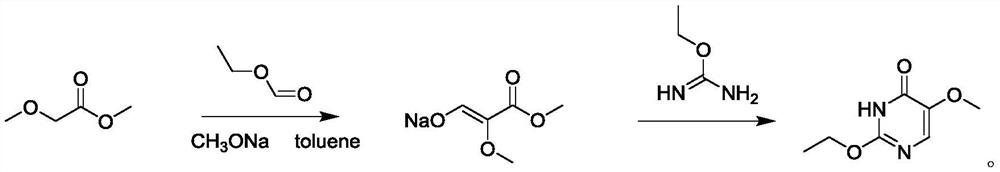

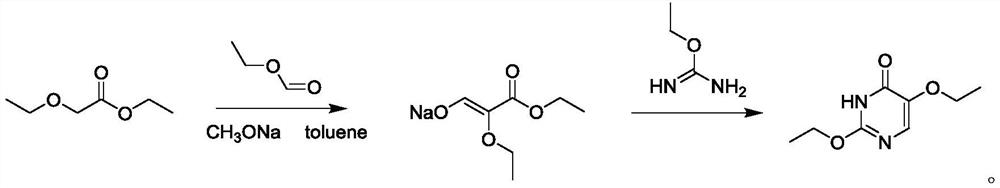

[0027] One aspect of the embodiments of the present invention provides a method for preparing 2-ethoxy-5-fluorouracil impurity, which comprises the following steps:

[0028] (1) Using methyl methoxyacetate or ethyl ethoxyacetate as raw material, sodium methoxide as alkali hydrogen extraction, and toluene as solvent, respectively drop raw material and ethyl formate in a uniform mixing system, and react to form 2 - Ethoxy-5-fluorouracil impurity intermediate;

[0029] (2) Add ethoxyisourea dropwise to the 2-ethoxy-5-fluorouracil impurity intermediate, adjust the pH to 9-10, then sequentially perform heating, vacuum distillation, adding water to dissolve, and purify to obtain 2 -Ethoxy-5-fluorouracil impurity crude product;

[0030] (3) Add water to dissolve the crude 2-ethoxy-5-fluorouracil impurity, and then sequentially cool and crystallize with ice water, suction filter, wash with water, and dry to obtain the 2-ethoxy-5-fluorouracil impurity.

[0031] In some preferred embo...

Embodiment 1

[0055] Synthesis of Impurity 1:

[0056] In a dry and clean 500mL three-necked flask, add 157g of methanol solution of sodium methoxide and stir, distill under reduced pressure to a fine powder, add 67g of solvent toluene, stir while adding, control the temperature at 10-15°C, add 56g of ethyl formate and 35g of methyl methoxyacetate, after the dropwise addition, it was naturally raised to room temperature, heated to 40°C, kept for 4-5h, and allowed to stand overnight after returning to room temperature.

[0057] Control the temperature of the reaction system at 10-15°C, add 95g of ethoxyisourea dropwise, adjust the pH to 9-10, heat to 40°C, and keep the reaction for 4-5h. The solvent was distilled off under reduced pressure, and the system was dark yellow viscous syrup. Add 100 g of water and stir to dissolve, add 30 ml of saturated saline to break the emulsion, extract with dichloromethane, collect the organic phase and concentrate to obtain 8.1 g of crude product. To the cr...

Embodiment 2

[0062] Synthesis of Impurity 1:

[0063] Add 157g of methanol solution of sodium methoxide into a dry and clean 500mL three-neck flask, stir, distill under reduced pressure to fine powder, add 67g of solvent toluene, stir while adding, control the temperature at 10-15°C, and add 56.2g of ethyl formate dropwise And 35.4g of methyl methoxyacetate, after the dropwise addition, it was naturally raised to room temperature, heated to 40°C, kept for 4-5h, and allowed to stand overnight after returning to room temperature.

[0064] Control the temperature of the reaction system at 10-15°C, add 99g of ethoxyisourea dropwise, adjust the pH to 9-10, heat to 40°C, and keep the reaction for 4-5h. The solvent was distilled off under reduced pressure, and the system was dark yellow viscous syrup. Add 100 g of water and stir to dissolve, add 30 ml of saturated saline to break the emulsion, extract with dichloromethane, collect and concentrate the organic phase to obtain 8.7 g of crude product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com