Solution type corn cationic starch and preparation method thereof

A technology of cationic starch and corn starch, which is applied in the field of starch denaturation, can solve the problems of relatively high equipment and process requirements, residual impurity content of reagents, high reaction efficiency of semi-dry method, etc., and achieve uniform reaction, less reagent residue and good retention effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

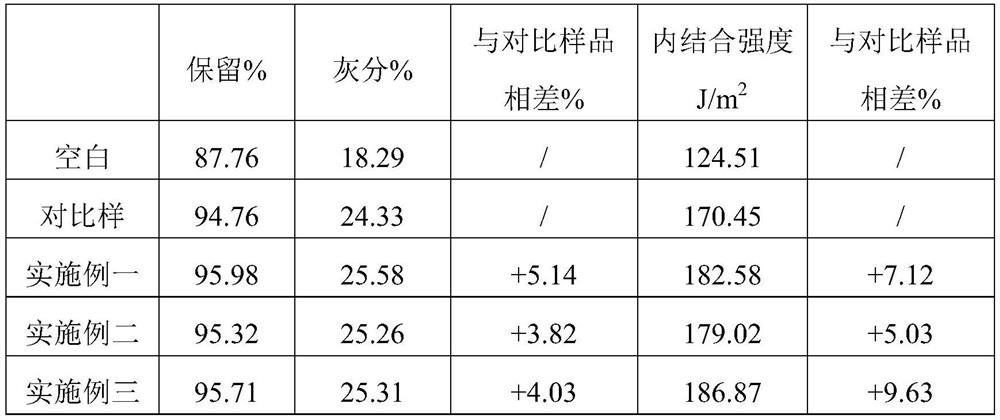

Examples

Embodiment 1

[0031] The present embodiment provides a kind of solution type corn cationic starch and preparation method thereof, and specific preparation method comprises the following steps:

[0032] Step 1: Add cornstarch and deionized water into a four-port fired glass reactor and keep stirring, then add an appropriate amount of NaCl into it at a stirring speed of 450r / min, stir evenly and divide into two parts.

[0033] Step 2: Warm up the two solutions to 60°C, add ammonium persulfate as a shearing agent and initiator to one of them, and then add a certain amount of NaOH solution as a catalyst to make it react in an alkaline environment for 1 hour, record Make E1; add only NaOH solution with the same volume as E1 to another solution, and react for 1 hour in the same way, and record it as E2.

[0034] Step 3, add an appropriate amount of sodium sulfite to E1, remove excess ammonium persulfate, and record it as E3; then add E3 to E2 and mix well, and the mixed solution is recorded as E4...

Embodiment 2

[0048] The present embodiment provides a kind of solution type corn cationic starch and preparation method thereof, and specific preparation method comprises the following steps:

[0049] Step 1: Add cornstarch and deionized water into a four-port fired glass reactor and keep stirring, add an appropriate amount of NaCl into it, stir at a speed of 450r / min, stir evenly and divide into two parts.

[0050] Step 2: Warm up the two solutions to 60°C, add sodium hypochlorite as a shearing agent and initiator to one of them, and then add a certain amount of NaOH solution as a catalyst to make it react in an alkaline environment for 1 hour, denoted as E1 ; To another solution, only add the same volume of NaOH solution as E1, also react for 1h, denoted as E2. Add an appropriate amount of sodium bisulfite to E1, remove the excess sodium hypochlorite, and record it as E3; then add E3 to E2 and mix well, and the mixed solution is recorded as E4; then add an appropriate amount of epichloro...

Embodiment 3

[0064] The present embodiment provides a kind of solution type corn cationic starch and preparation method thereof, and specific preparation method comprises the following steps:

[0065] Step 1: Add cornstarch and deionized water into a four-port fired glass reactor and keep stirring, add an appropriate amount of NaCl into it, stir at a speed of 450r / min, stir evenly and divide into two parts.

[0066] Step 2: Warm up the two solutions to 60°C, add sodium hypochlorite as a shearing agent and initiator to one of them, and then add a certain amount of NaOH solution as a catalyst to make it react in an alkaline environment for 1 hour, denoted as E1 ; To another solution, only add the same volume of NaOH solution as E1, also react for 1h, denoted as E2. Step 3, add an appropriate amount of sodium bisulfite to E1, remove excess sodium hypochlorite, and record it as E3; then add E3 to E2 and mix evenly, and the mixed solution is recorded as E4; then add an appropriate amount of cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com