Acrylic pressure-sensitive adhesive tape as well as preparation method and application thereof

A technology of acrylic pressure-sensitive tape and acrylic pressure-sensitive adhesive, which is applied in the direction of pressure-sensitive film/sheet, adhesive, adhesive type, etc., and can solve the problems of initial tack, stickiness, peel strength balance, pressure sensitivity, etc. The tape is easy to degumming, residual glue, poor temperature resistance and water resistance, etc., to achieve good invisible effect, strong cohesive force and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

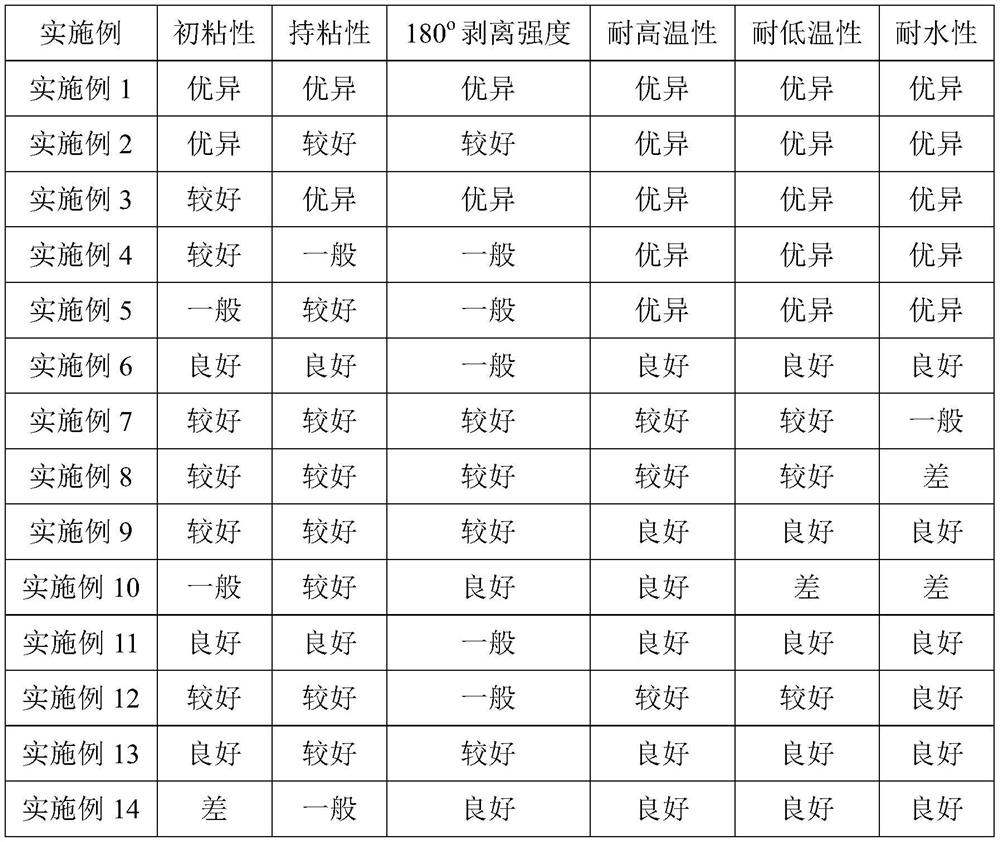

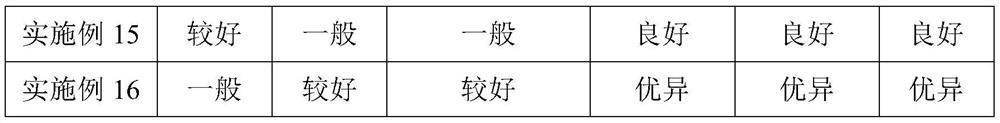

Examples

preparation example Construction

[0086] Among the present invention, the preparation method of described polyacrylic acid resin comprises the following steps:

[0087] (1) Add monomer Ⅰ, monomer Ⅱ and monomer Ⅲ into the reactor, stir evenly, add solvent, and heat up to 45-65°C while stirring in an inert gas environment;

[0088] (2) Add initiator, stir and heat up to 70°C-85°C, react until the solid content of the mixed material is 30%-70%, and the viscosity is 1000-50000cps, stop the reaction;

[0089] (3) Cool to below 40°C and discharge for later use.

[0090] The inventor believes that the best reaction temperature is preferably not lower than 80°C, preferably 85°C, and the transparency of the prepared glue solution is the best.

[0091] The viscosity test method is to use the NDJ-8S rotational viscometer produced by Shanghai Pingxuan Scientific Instrument Co., Ltd. to test against the GB / T2794-1995 standard.

[0092] The test method of glue solid content is:

[0093] Step 1: Cut the aluminum foil into...

Embodiment 1

[0118] Embodiment 1 provides a kind of acrylic pressure-sensitive adhesive tape, and described adhesive tape comprises substrate and the acrylic pressure-sensitive adhesive that is coated on one side of substrate; The other side of substrate is coated with release coating; Described substrate is PE Film, thickness is 0.07mm, purchased from Dongqiao Plastic Co., Ltd., Zhongshan City; the thickness of the release coating is 0.2 μm, and the material is a silicone release agent, purchased from Hubei New Sihai Chemical Co., Ltd.; the curing The agent is n-butanol etherified melamine formaldehyde resin, purchased from Shanghai Xinhua Resin Co., Ltd.;

[0119] The raw materials for the preparation of the acrylic pressure-sensitive adhesive include at least the following components in parts by weight: 80% polyacrylic resin, 16% tackifying resin, and 4% curing agent; the tackifying resin is olefin resin, vitrified The transformation temperature is 80±5°C, purchased from Shanghai Danfan...

Embodiment 2

[0130] Embodiment 2 provides a kind of acrylic pressure-sensitive adhesive tape, and described adhesive tape comprises substrate and the acrylic pressure-sensitive adhesive that is coated on one side of substrate; The other side of substrate is coated with release coating; Described substrate is PE Film, thickness is 0.065mm, purchased from Dongqiao Plastic Co., Ltd., Zhongshan City; the thickness of the release coating is 0.01 μm, and the material is a silicone release agent, purchased from Hubei New Universal Chemical Co., Ltd.; the curing The agent is n-butanol etherified melamine formaldehyde resin, purchased from Shanghai Xinhua Resin Co., Ltd.;

[0131] The raw materials for the preparation of the acrylic pressure-sensitive adhesive include at least the following components in parts by weight: 75% polyacrylic resin, 20% tackifying resin, and 5% curing agent; the tackifying resin is olefin resin, vitrified The transformation temperature is 80±5°C, purchased from Shanghai ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com